Straw charcoal machine plays an essential role in the recycling of agricultural biomass wastes. It turns crops straws, wood stick, and weed into charcoal through the process of carbonization. The production process of the Lifting Type Carbonization Furnace is safe, clean, and efficient. The high-quality straw charcoal produced by the machine has great utilization value. It has wide applications in agriculture, industry, and carbon credit platforms. Therefore, investing in this kind of machine has great market prospects.

Hazards of Improper Straw Handling

Straw is a potential biomass energy resource. If handled properly, it can be used as biomass energy. However, improper handling not only leads to the waste of these resources but more importantly, it brings harm.

Environmental Pollution

Direct burning of straw may result in the release of smoke and harmful gases. These pollutants are detrimental to air quality and the atmosphere. Moreover, it will exacerbate environmental problems such as smog and acid rain.

Decreased Soil Quality

If straw accumulates in the field for a long time, it will cause the soil quality to deteriorate. The accumulation of straw will hinder the aeration and water penetration of the soil. thereby affecting crop growth. It even leads to land degradation.

Fire Risk

Improper straw handling methods, such as littering or burning, can easily start a fire. Especially during the dry season, the spread of fire can cause serious damage. This machine can solve waste resource management issues in an eco-friendly and safe manner.

Multiple Uses of Straw to Charcoal Processing Machine

Lifting Type Carbonization Furnace can accept a large range of raw materials except for crop straws, wood sticks, and weeds. It also can turn all the biomass or organic wastes (rice hull, sludge sewage, coconut shells, palm kernel shells, etc.) into charcoal.

Wide Application of End Products from Straw Charcoal Machine

High-Quality Charcoal

Carbon credit acquisition. Charcoal production and use are recognized in the carbon credit market as a carbon reduction measure. It can earn carbon credits.

High-temperature furnace material: Charcoal can be used as fuel in high-temperature furnaces for smelting metals, and producing glass, and ceramics.

Cooking and Heating: Charcoal not only produces high heat but also produces less smoke. Therefore, it is widely used for cooking and heating in life.

Soil Improvement: Charcoal can be used as a soil amendment to improve soil structure. Applying charcoal to soil can help improve soil fertility.

Wood Vinegar

Food preservation. Wood vinegar is often used in the food industry for anti-mildew, anti-bacteria, and anti-oxidation.

Soil disinfection. Wood vinegar can effectively kill pests in the soil that hinder plant growth.

Plant growth regulation. Wood vinegar can promote the growth of vegetables, fruits, and other plants.

Wood Tar

Building Sealing. Wood tar can be used to seal building materials. It can fill in the cracks. This prevents water and gas penetration.

Wood Preservation. Wood tar is painted on the surface of wood products to protect the wood from insects, fungi, and decay.

Carbon black production. Wood Tar is an important raw material for carbon black manufacture. It is widely used in the rubber industry.

Lifting Type Carbonization Furnace has high yield and high-value end-products, thus you can get a high return from your investment in this waste-to-fuel business.

Different Types of Carbonization Equipment

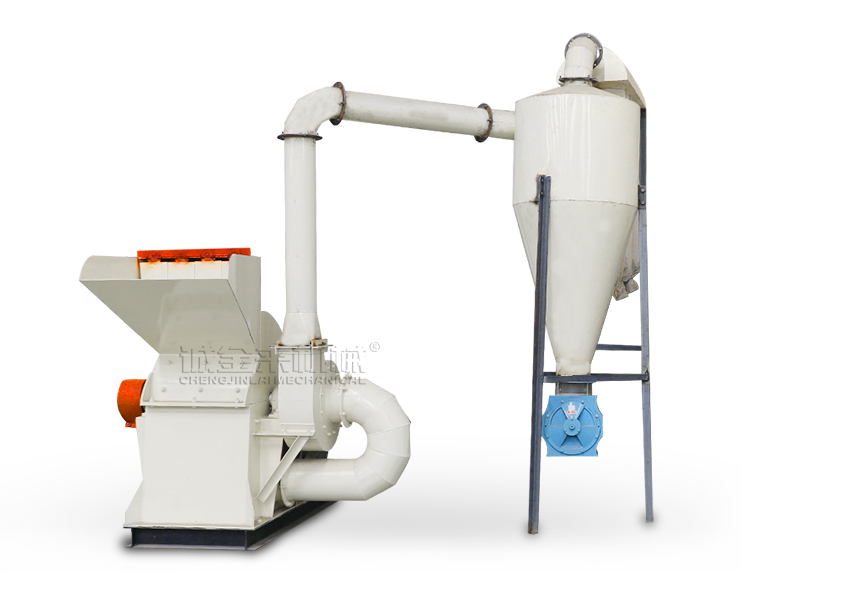

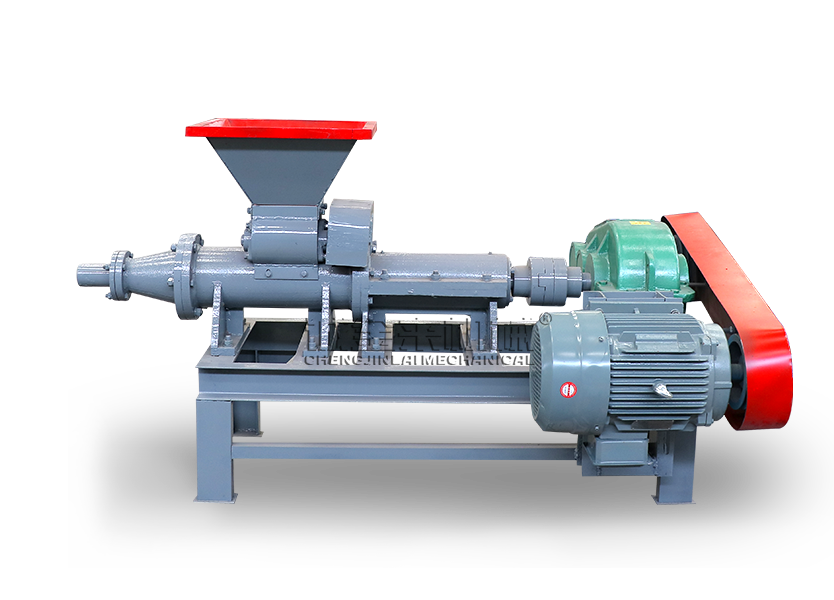

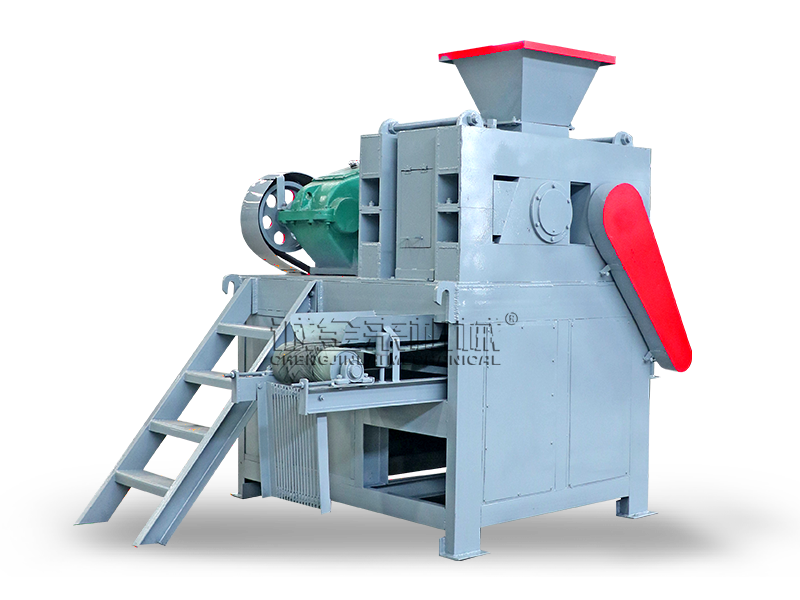

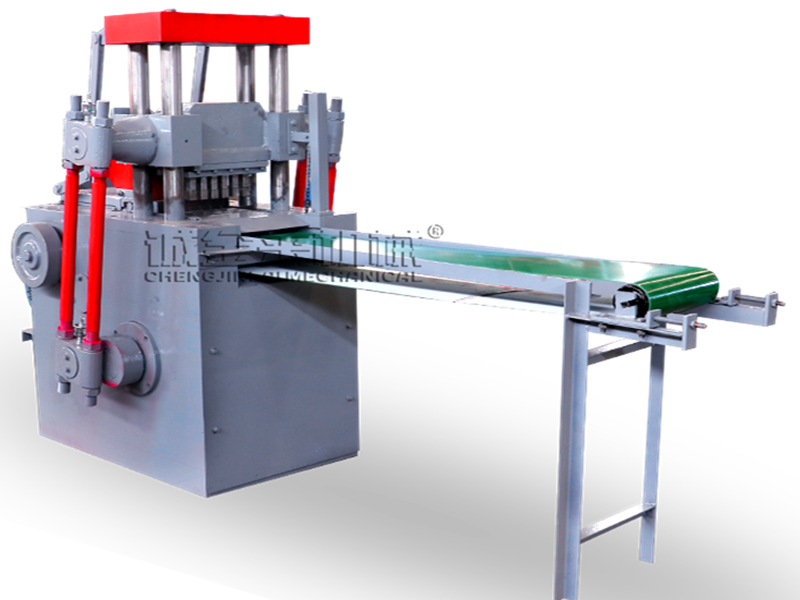

Production Line

Now you can roughly see the production line we designed for our customer, if you have special needs, we can design the production line according to your needs.

Our professional team can provide you with free production line planning according to your requirements!

Related Products

Making Equipment

Wechat

Wechat

+8613838093177

+8613838093177