What’s Continuous Carbonization Furnace ?

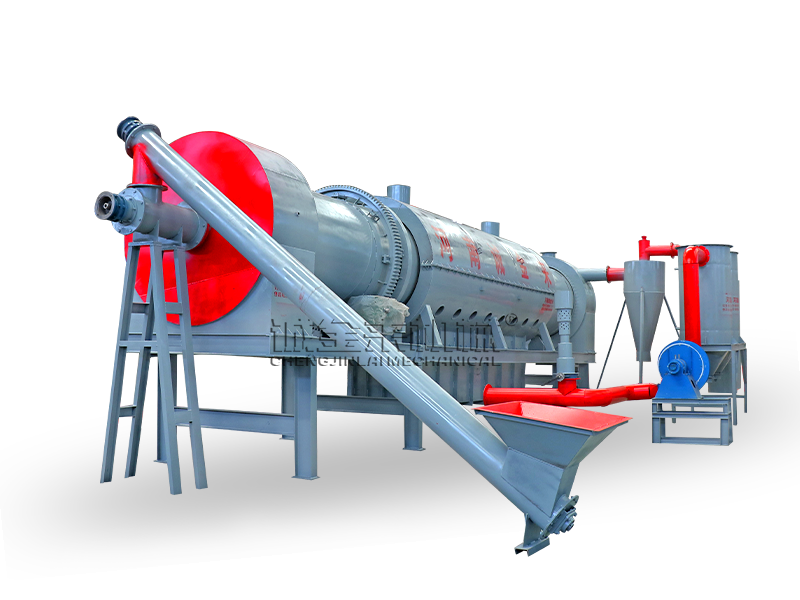

Continuous Carbonization Furnace is a new type of environmentally friendly carbonization equipment. The biomass material is converted to charcoal after passing through a carbonization stove and can be further processed. Compared with other carbonization equipment, this carbonization furnace for briquette can work continuously for 24 hours to achieve high output, so it is called continuous carbonization furnace. The entire production process does not produce harmful gases, does not pollute the environment, and is excellent in various carbonization furnaces.

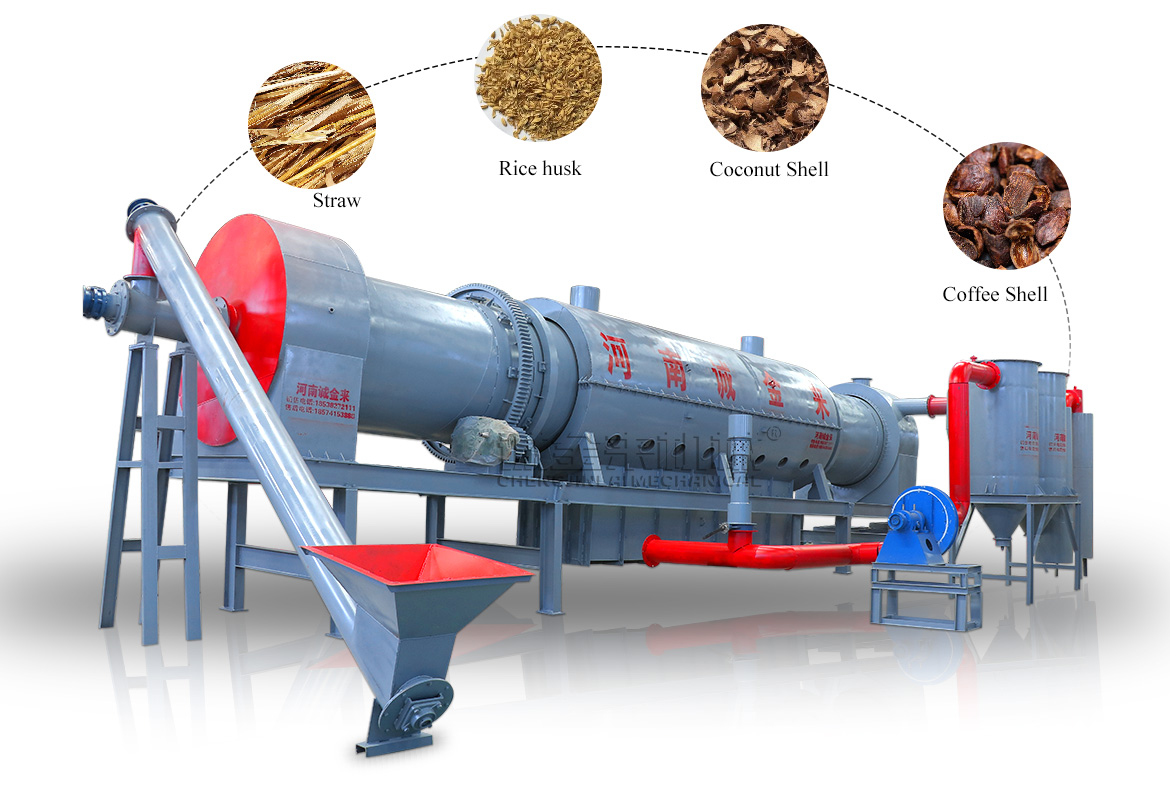

Raw Materials and Final Products

Continous Carbonization Furnace is mainly used for:

olive seeds, nut shells, animal bones,peanut shells, sawdust, corn stalks, bagasse, tree branches, rice husks,bamboo chips, sorghum stalks, sunflower husks, coconut shells, apricot husks, coffee grounds,cotton stalks , Chinese medicine residue, hemp stalk, palm shell, electronic waste, cans,waste wires, sludge, household garbage and other materials with biomass properties are carbonized.

(size less than 30mm, moisture less than 15%)

Product Advantages

- Heating method: gas, natural gas, wood, coal, etc. are available for various options. Equipped with one-key ignition, safe and reliable.

- Control system: high degree of automation, temperature controllable, air leakage alarm.

- Flue gas recovery device: It recovers and reuses combustible gases such as carbon monoxide, methane, and oxygen produced during the carbonization process to save fuel.

- Cooling system: Cooling by circulating water and equipped with high-efficiency large-capacity evaporation tower, high efficiency, to ensure the quality of the finished product.

Working principle

When the continuous carbonization furnace is working, the sawdust, rice husk, coconut husk, etc. and various biomass raw materials (size less than 30mm, moisture less than 15%) that need to be carbonized (size less than 30mm, moisture less than 15%) are heated to 300°C through a gasification furnace or a fire box. The feeding screw is conveyed and sent into the carbonization drum through the screw propeller. Dehumidification, decomposition and carbonization are carried out in a high temperature (heating temperature can reach 600°C) and an oxygen-free environment.

The flue gas and combustible gas produced in this process are uniformly processed by the flue gas purification and recovery device to achieve smokeless emission; after the combustible gas is collected, it will flow to the bottom of the furnace for recycling and use. In this process, it will form a continuous feed. Material, the effect of continuous carbonization, so as to achieve continuous production.

Models and Types of Continuous Carbonization Furnace for Sale

| Model | Capacity | Motor Power | Weight | Size(M) |

| L1 | 200-300kg/h | 22KW | 8-9T | 12.5*5.5*3 |

| L2 | 300-500kg/h | 28KW | 9-10T | 12.5*6.5*4.5 |

| L3 | 500-800kg/h | 28KW | 12-14T | 12.5*7.5*5.5 |

| L4 | 800-1200kg/h | 32KW | 14-16T | 12.5*7.5*5.5 |

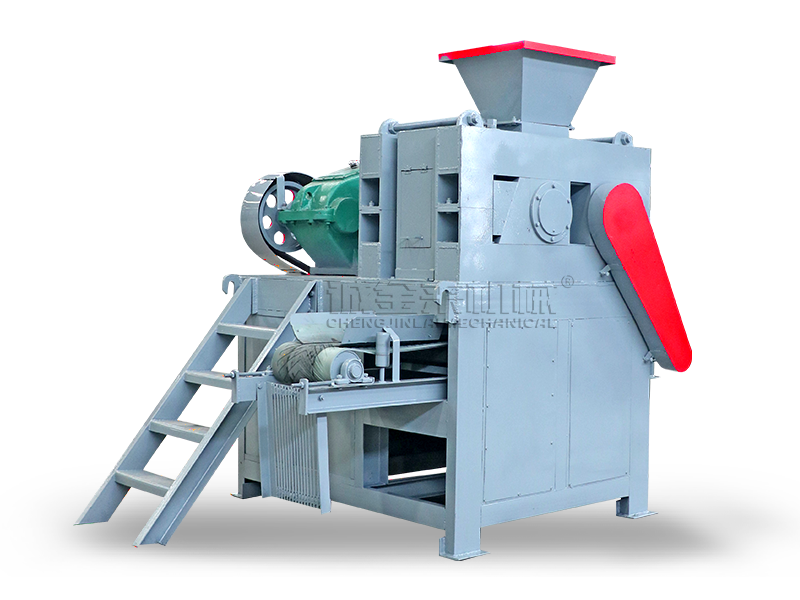

Unique Continuous Carbonization Furnace Design from Chengjinlai

You can purchase with confidence as our products are guaranteed to be of high quality and manufactured strictly according to national and international standards.

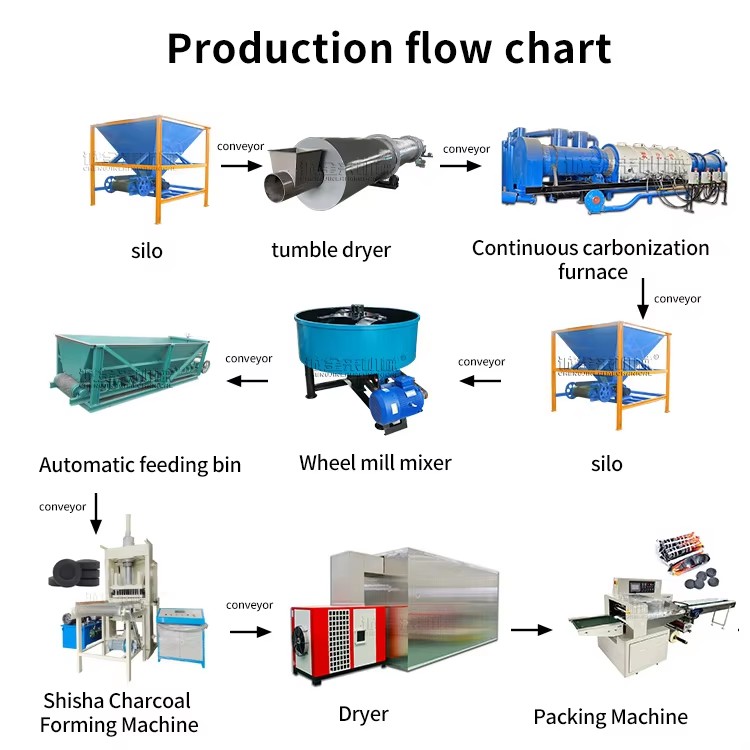

Charcoal Making Process

We have professional engineer team can provide flow chart solution base on your project infos, like: raw material, processing capacity, usage etc, please contact us if you need. We can make the most suitable production line for your plant.

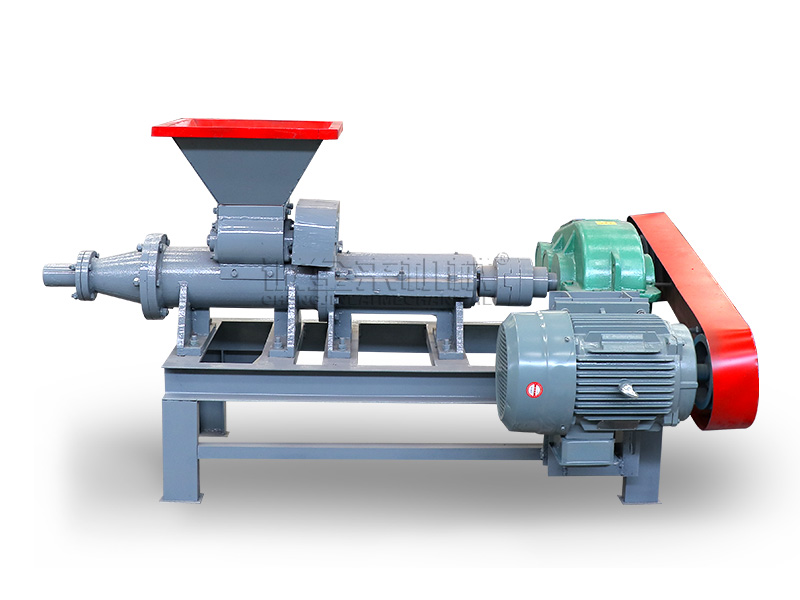

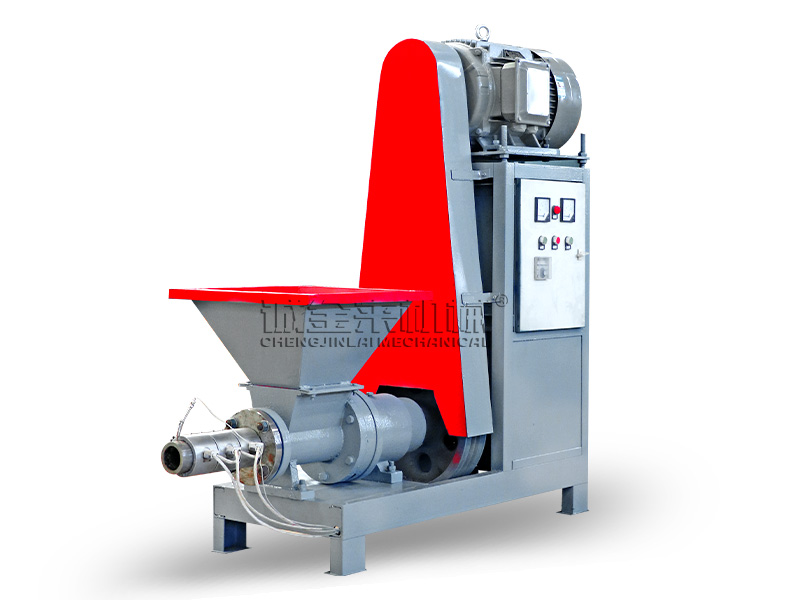

♦Secondly, biomass powder can be shaped by sawdust briquette machine.

♦In the end, sawdust stick can be carbonized by carbonization furnace.

The whole charcoal furnace stove, charcoal machine burn wood and rice husk carbonization furnace production line are fully automatic.

♦Firstly, rice husk, sawdust or other biomass are crushed by dust free crusher and dryer.

♦Secondly, biomass powder can be shaped by sawdust briquette machine.

♦In the end, sawdust stick can be carbonized by carbonization furnace.

The whole charcoal furnace stove, charcoal machine burn wood and rice husk carbonization furnace production line are fully automatic.

Packing & Shipping

1,Small size equipment is packed by wooden case which delivery by LCL shipping .

2, Big size equipment is water-proof packing which delivery by full container load,small parts will be packed into wooden case.

3, Special packing requirement as customers requirement.

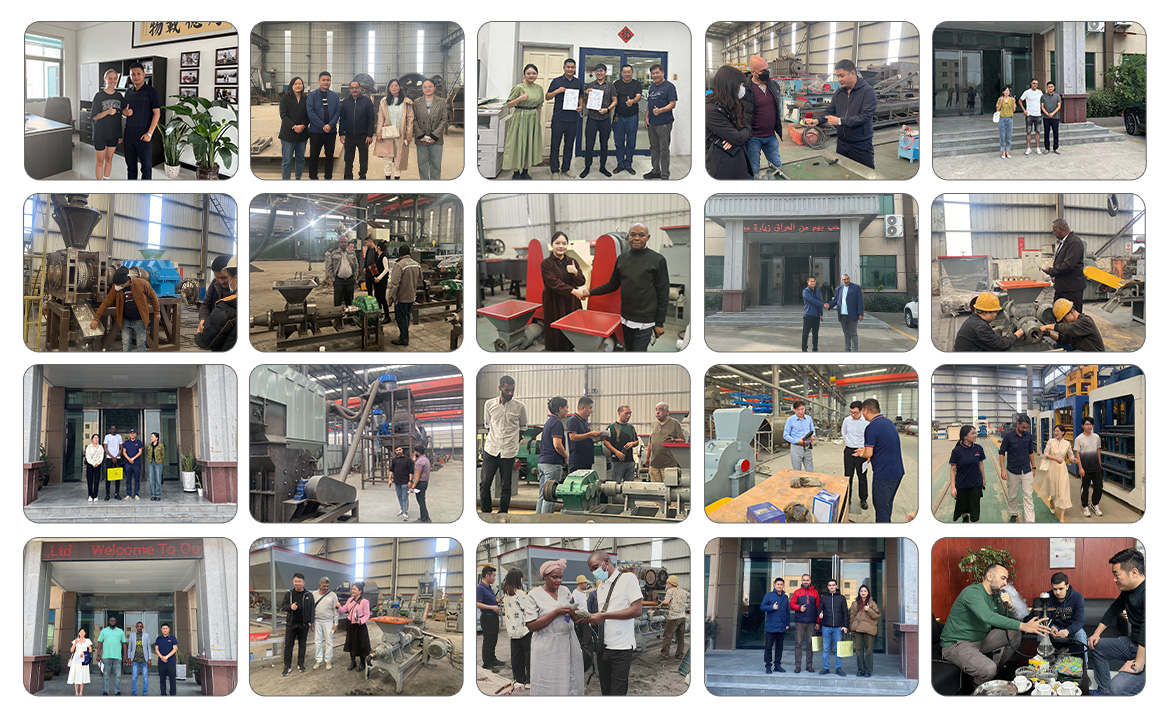

Starting Your Business Here!

Until now, we have customers more than 130 countries, Indonesia, India, Malaysia, Laos, Myanmar, Thailand,Vietnam,Philippines,Pakistan, Sri Lanka, Lebanon, Georgia, Turkey, Poland, Czech, Mongolia, South Korea, Romania, Egypt, Sudan,Tunis,Algeria, Ethiopia, Tanzania Equatorial Guinea, Zambia, Mexico, South Africa, etc.

You’re welcome if you’d like to visit our factory! You can contact us now!

Related Posts

Wechat

Wechat

+8613838093177

+8613838093177