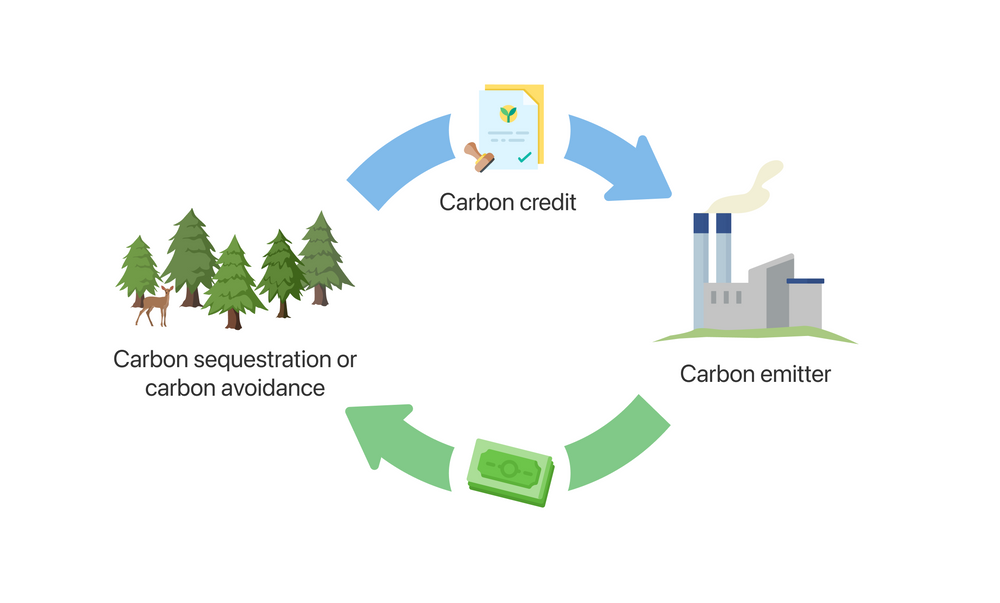

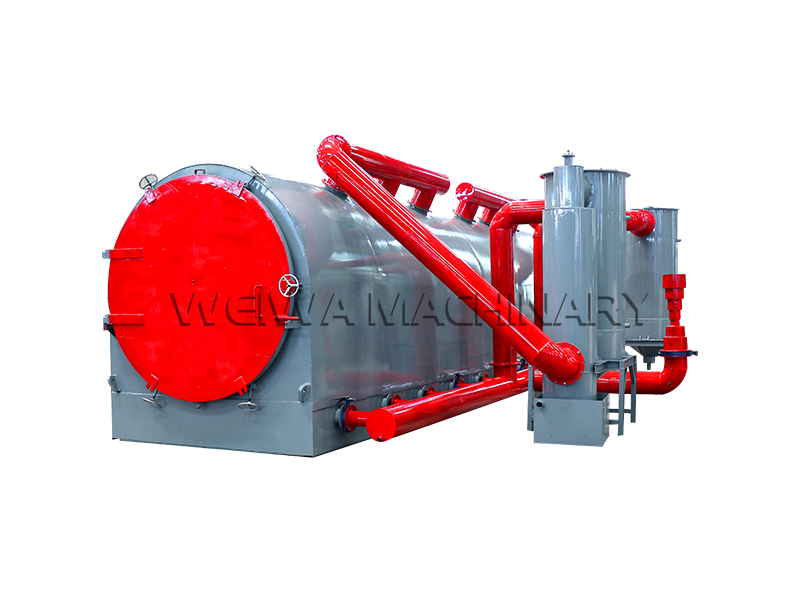

Horizontal Charcoal Furnance adopts the advanced carbonized technology heat flow, uses a unique storage chamber structure,make full use of the flue gas produced by carbonization.It is used to make charcoal from the wood and all kinds of biomass.The operation is very convenient, good safety, high production efficiency, can save a lot of energy, good environmental protection performance, simple and convenient, need not power and mobile production.It ensures that the entire process does not produce harmful gases and does not pollute the environment, with this machine you can get carbon credit directly.It is an ideal equipment of family,large and medium scale production of charcoal.

What is the operating instructions of horizontal charcoal making machine?

- Feeding raw material and sealing the furnace → Preheating and drying the raw material → Anaerobic carbonization → Cooling and discharging the carbon.

- Preparing the materia, if it’s the wood, please make sure the size is not with big different;

- Open the furnace door, and put the mateiral inside directly; or you can put the mateiral on the trolley to send the material into the inner pot.

- Seal the furnace, and check the valves and other things, make sure the furnace is ok before firing.

- FIre the furnace and to make the charcoal. This step, there is the combustible gas to produce and this gas can be sent to the bottom of the fire mouth to let the machine heat.

- After the charcoal finished and cooled, then use the trolley to delivery the charcoal out.

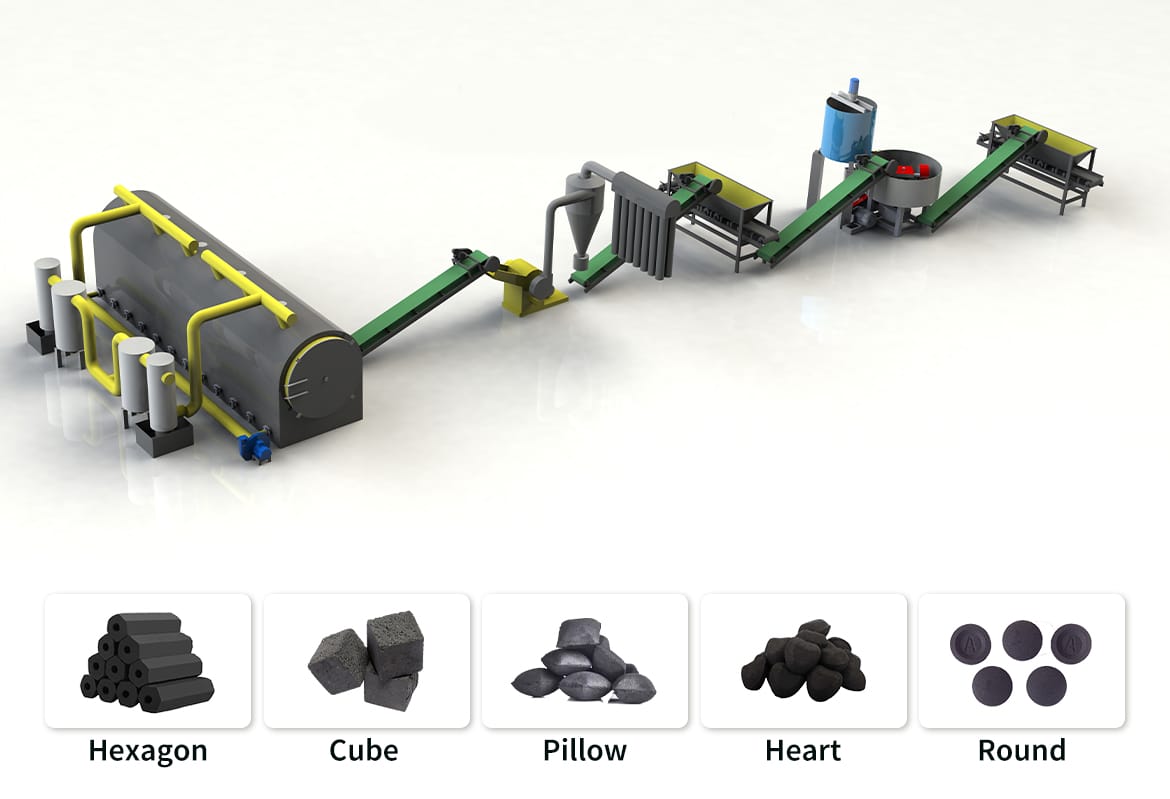

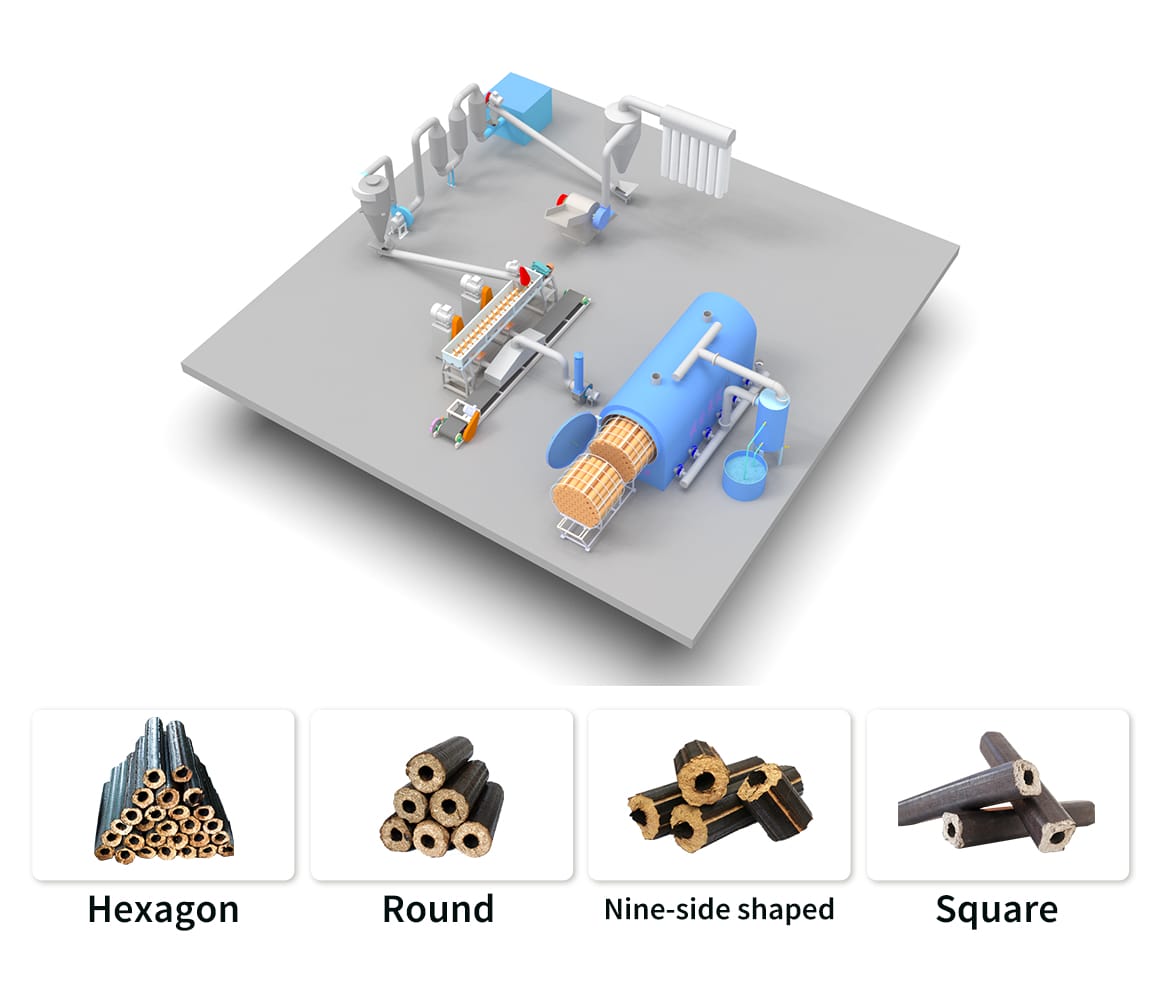

Optional Charcoal Briquette Machine: Add Value with Ease

A charcoal briquette machine significantly enhances the value of briquette charcoal by transforming loose biochar powder into compact, energy-dense briquettes (rod, spherical, cubic, and hexagonal shapes, etc.). Here’s how it boosts the utility and value of charcoal:

Higher Energy Density

Briquetting charcoal increases its energy density, making it an efficient and longer-burning fuel. This characteristic makes charcoal briquettes popular for cooking, heating, and industrial uses, providing a cost-effective alternative to conventional fuels like coal or wood.

Compact Form and Easy Storage

Charcoal briquettes are compact and uniform, allowing for easier storage, transportation, and handling compared to loose charcoal. This consistency appeals to customers, especially in bulk, because it reduces wastage and facilitates efficient storage.

Higher Market Value

Briquetting adds significant commercial value to charcoal by creating a refined product that’s ready for diverse uses. Compared to raw charcoal, briquettes fetch a higher price in the market, especially with increasing demand for eco-friendly alternatives.

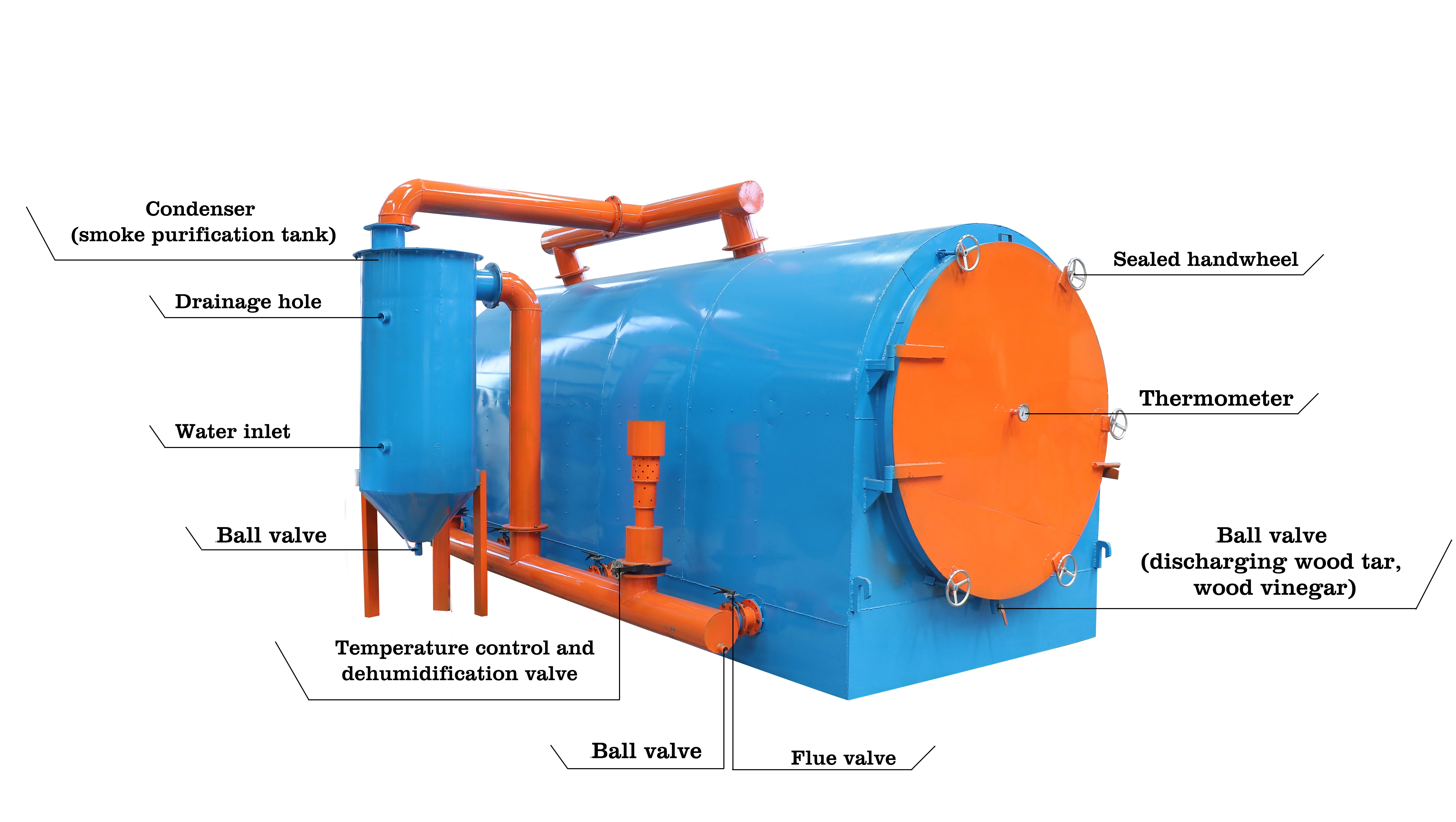

Unique Horizontal Carbonization Furnace Design

These are the main technical parameters of the product, if you do not know how to choose, you can tell us the raw materials you want to process. We will help you choose the best product for you.

Thermometer : Measuring furnace temperature.

Sealing cap:Seal to maintain the temperature inside the furnace, to ensure into a good effect of carbonization.

Combustion Chamber: Fire the furnace and to make the charcoal. There is the combustible gas to produce and this gas can be sent to the bottom of the fire mouth to let the machine heat.

Carbonization Chamber:The raw materials are thermally decomposed in combustion chamber to generate a large amount of acetic acid, methanol, wood tar and other liquid products; also produced combustible gases such as methane and ethylene.

Smoke recovery system:The flammable gases are treated by flue gas purification, and are returned to the carbonization machine for burning, providing heat to the carbonization furnace, increasing the furnace temperature, and generating carbon at high temperatures.

Convenient feeding and unloading:The horizontal carbonizing furnace is eguipped with rails and trolley, which can make full use of the space in thefurnace, which is more convenient to use and reduces the labor intensity of workers.

Raw Materials Available for Horizontal Carbonization Furnace

New model horizontal charcoal carbonizer furnace can directly carbonize (Bulky timber): fruit tree, bamboo, wood branches, wood blocks, coconut shell, waste wood, trunks, wood logs, stumps, roots, wooden pallet, corncob, furniture factory scrap.

Fine powder or granular materials(The fine, small and flake biomass powder must first be formed into wood chip sticks by a wood chip forming machine, which can be carbonized by a horizontal carbonization furnace.)

like:sawdust, shavings, wood chips, rice husk, rice grams, peanut shell, wood chips, nut shells, palm shells, cashew nut shell, hemp straw, biomass, some crops, semi-coke bark, furfural residue.

How to Use Horizontal Carbonization Furnace to Bring Good Economic Profit

Take bamboo charcoal as an example

Carbon Sequestration

Bamboo biochar is rich in carbon and has a stable structure, allowing it to store carbon in the soil for many years. This long-term carbon sequestration helps reduce the harmful effects of carbon dioxide on the environment.

Heating Fuel & BBQ & Hookah

Bamboo charcoal has a fixed carbon content of over 80%, making its calorific value about 30% higher than wood charcoal. Therefore, it suits to be:

- used as fuel in cement plants, power factory, brick plants, etc.

- used for BBQ or Hookah.

Soil Improvement

Bamboo biochar is a good material to improve soil quality. It can:

- increase nutrient retention and promote plants’ healthier growth and higher yields.

- regulate soil pH, etc.

- improve soil aeration and drainage and enhance soil structure;

Models and Types of Horizontal Carbonization Furnace for Sale

| Model(m) | Input Capacity(t/h) | Dimension(m) | Weight(kg) |

| 1.0*1.5 | 3.8-4 | 1.0*1.5*1.8 | 600 |

| 1.5*3.0 | 6-8 | 1.5*3.0*2.2 | 1800 |

| 2.0*4.5 | 8-10 | 2.0*4.5*2.2 | 3500 |

| 2.0*6.0 | 12-16 | 9.0*2.4*2.9 | 5000 |

Applications of the horizontal charcoal making machine furnace

Other types of carbonization furnaces, such as continuous carbonization furnaces and lifting carbonization furnace are important equipment for the production of charcoal.

Therefore, charcoal producers and charcoal processing plants should choose their own carbonization machines according to their actual production needs.

Continuous Carbonization Furnaces

Lifting Carbonization Furnace

Why do so many manufacturers choose Weiwa horizontal carbonization furnace?

By summarizing the past data of seling, we can find that this horizontal carbonization furnace is popular with charcoal suppliers.Why? Because it has many advantages which can attract biochar manufacturers to invest in as follows:

Stocks

We have a lot of stocks,we can delivery quickly.

Cerificate

We have obtained many cerification,so you don’t need worry about the quality of our machine.

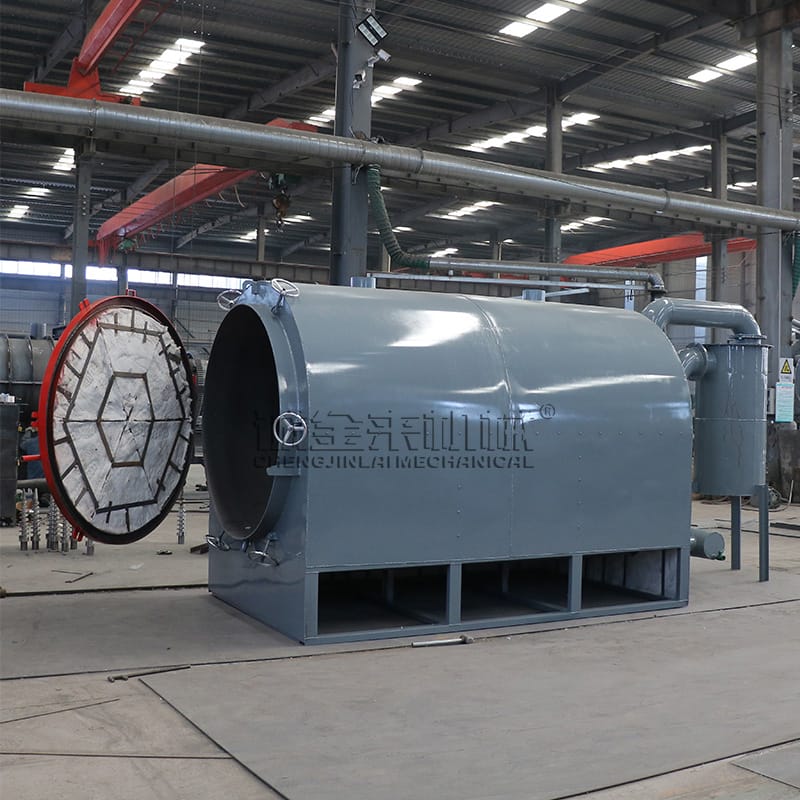

Factory

We are factory,we can provide the same quality machine with a lower price.

Henan Weiwa Machinery Manufacturing Co., Ltd. is a professional manufacturer of charcoal manufacturing machinery in China. Continuous improvement and innovation is our production philosophy. Our tenet: Survive by quality, develop by credit, quality first, credit first, integrity-based, customer first.

Starting Your Business Here!

Until now, we have customers more than 130 countries, Indonesia, India, Malaysia, Laos, Myanmar, Thailand,Vietnam,Philippines,Pakistan, Sri Lanka, Lebanon, Georgia, Turkey, Poland, Czech, Mongolia, South Korea, Romania, Egypt, Sudan,Tunis,Algeria, Ethiopia, Tanzania Equatorial Guinea, Zambia, Mexico, South Africa, etc.

You’re welcome if you’d like to visit our factory! You can contact us now!

Related Posts

Wechat

Wechat