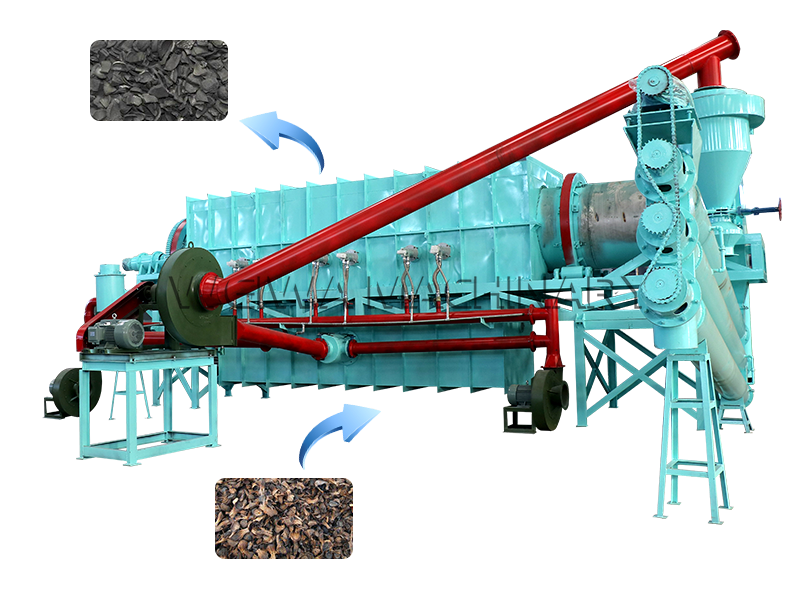

Palm kernel shell charcoal making machine is designed to convert palm kernel shell waste into charcoal through the biomass carbonization process. As a pioneer in the waste recycling plants manufacturing field, Weiwa Group can provide you with best quality palm shell kernel charcoal machine with perfect design, which can both save energy and protect the environment.

Know Palm Kernel Shells in Palm Cultivation and Palm Oil Industry

Palm Kernel Shell (PKS) is the hard outer shell of palm kernel fruit, which is left behind as a byproduct after palm oil extraction. It is a fibrous, brownish-yellow material with particle sizes typically ranging from 5 mm to 40 mm. Each year, the palm oil industry generates over 5 million tons of PKS. Utilizing a palm kernel shell biochar machine allows you to profit from the attractive palm kernel shell charcoal price. Now learn about this material.

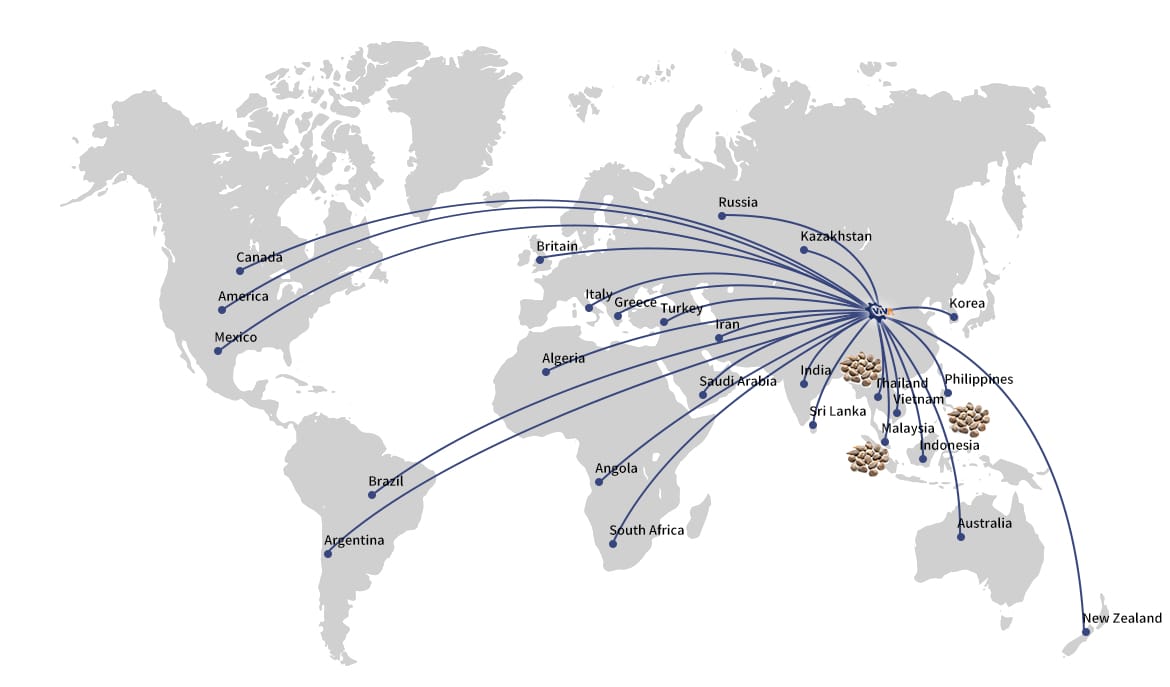

Major Producing Regions

The primary producers of PKS are countries where oil palm is a major economic crop. According to public data, the top PKS-producing regions include:Indonesia、Malaysia 、Thailand and etc.

Characteristics of Palm Shells

Palm kernel shells offer unique characteristics that make them ideal for charcoal production.

- High calorific value (around 4000 Kcal/kg)

- Low moisture content

- Easy crushing

- Low ash content

- Renewable, easy available and low cost

Palm Byproducts for Carbonization

In addition to PKS, some other palm byproducts be processed through carbonization

- Palm fiber;

- Empty fruit bunches (EFB);

- Palm dregs;

- Palm branches and leaves;

- etc.

How to Use Palm Kernel Shell Charcoal Making Machine?

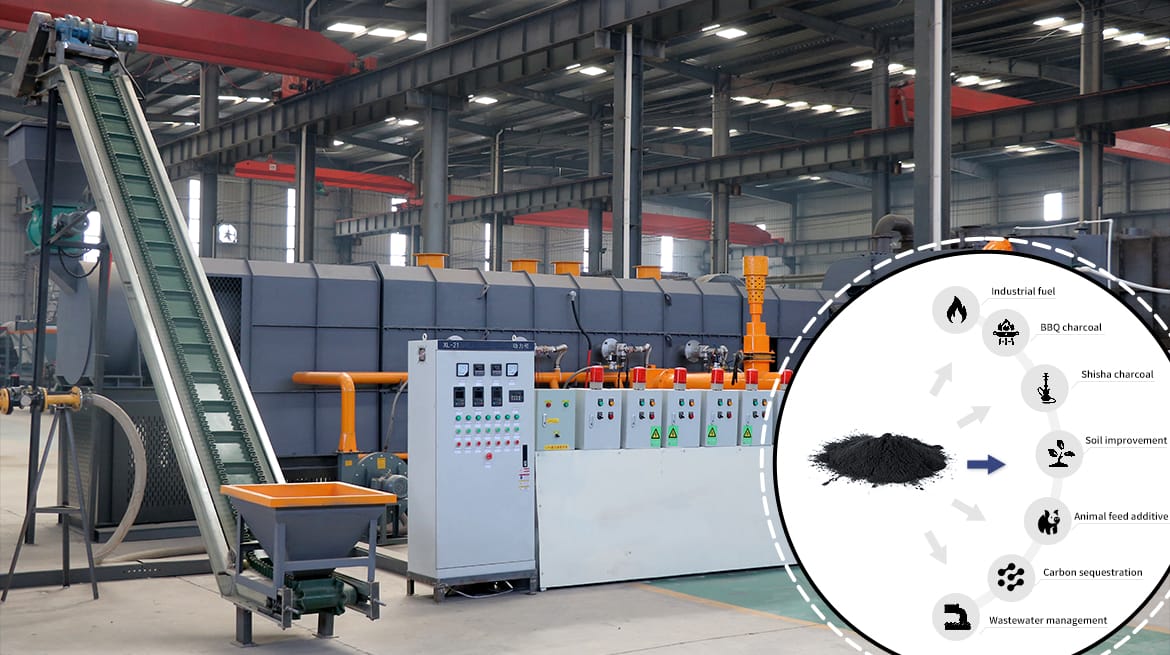

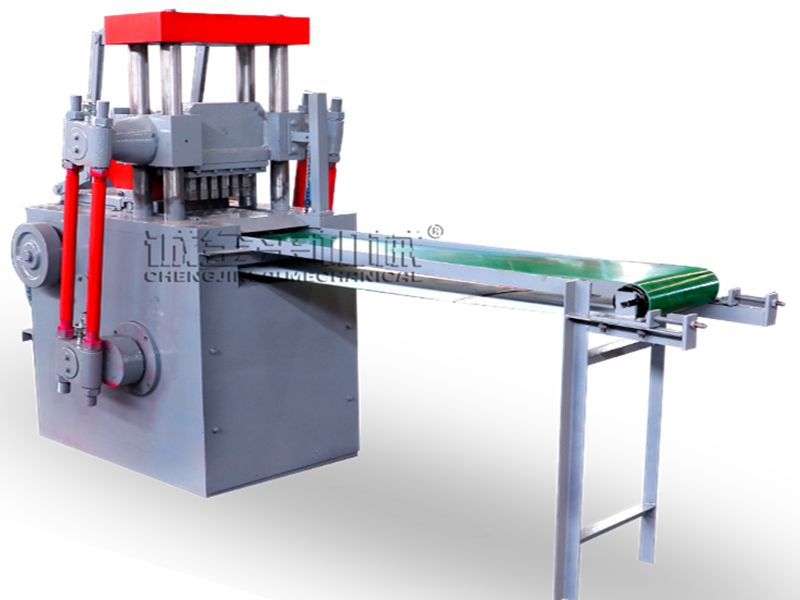

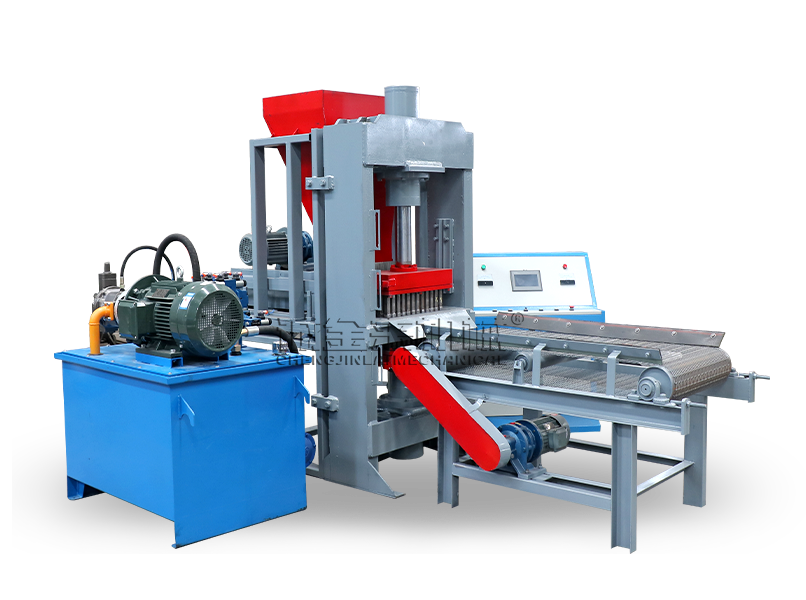

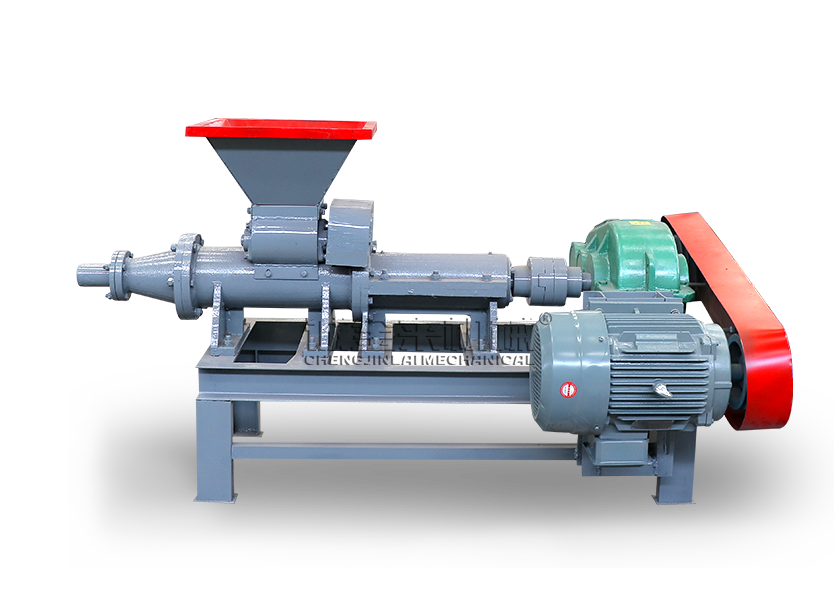

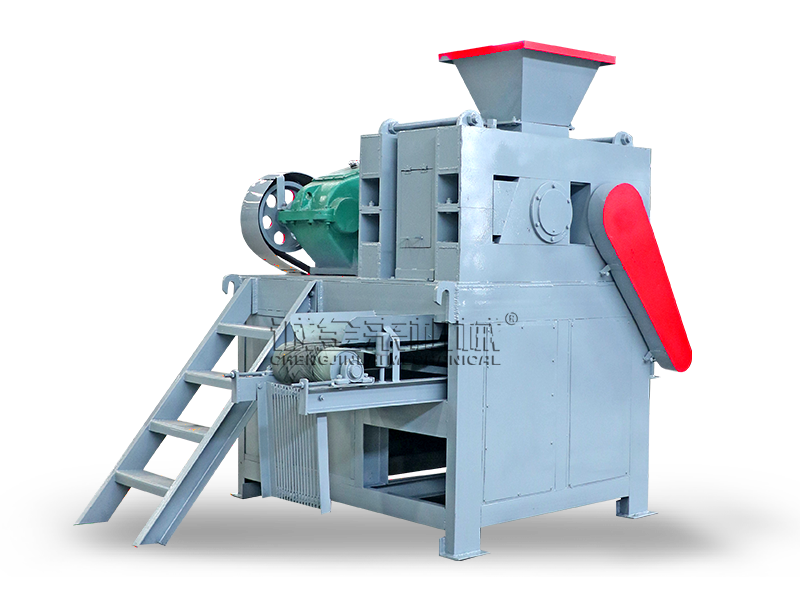

A complete palm kernel shell charcoal machine usually includes a material pretreatment line, a biomass carbonization part, and a charcoal briquette machine. This integrated system effectively transforms palm waste into valuable charcoal, optimizing the process for both efficiency and sustainability. See its working process.

Features of Palm Kernel Shell Charcoal Machine

Equipped with Alarm Device

The PLC electric cabinet has an alarm device, and there will be an alarm display and an alarm for some electrical failures.

With Explosion-proof Water Seal

There is an explosion-proof water seal at the combustible pipeline (to prevent abnormal pressure of combustible gas in the equipment)

Variable Frequency Fan Guide

The direction of the gas in all pipelines is led by the fan (the fan is variable frequency), and it will be displayed on the PLC when the pipeline is blocked.

High Heat Efficiency

The material is not in contact with the flue gas and is not polluted by hot air.

Good Energy-saving Effect

The heat utilization rate of this equipment is higher, the use of air heat ex-changer can effectively improve the thermal efficiency by 5-10%, and the energy saving effect is good.

Advantages of Palm Kernel Shell Charcoal Machine

Test Report of Palm Kernel Shell Charcoal

Note: The following are the test data for palm shell biochar produced by palm kernel shell charcoal machine. The data may vary due to material differences.

- Size: 5-20mm

- Calorific Value: high, at about 5500kcal/kg

- Fixed Carbon: high, about 77%

- Sulfur Content: very low, below 0.1% (very low compare to regular coke).

- Volatile Matter: about 10%

- Moisture Content: between 1% and 2%.

| Kind | Palm silk grain |

| Whole water Mt% | 2.35 |

| Analytical water Mad% | 1.32 |

| Dry basis ash Ad% | 20.75 |

| Volatile matter Vd% | 9.32 |

| Dry basis fixed carbon Fcad% | 68.61 |

| Sulfur content on dry basis St.d% | 0.42 |

| Coking Characteristics 1-8CRC | 1 |

| New national standard calorimeter dry basis high calorific value kcal/kg | 5485 |

| The new national standard calorimeter method receives the base low calorific value kcal/kg | 5265 |

| Remarks: The above data is for reference only |

Application Fields of Palm Kernel Shell Charcoal

The unique chemical properties of palm kernel shell charcoal bring a wide range of applications and significant economic value. The palm kernel shell charcoal is widely applied in agricultural, pharmaceutical, civilian, and other industries. Come on to start your investment of palm kernel shell charcoal making machine!

Carbon Sequestration

Feature: Abundant Carbon Content and Stable Chemical Structure

Application: Carbon Sequestration and Carbon Credits

Palm kernel shell charcoal’s high carbon content and stable chemical structure make it suitable for carbon sequestration initiatives. It can be used to capture and store carbon dioxide, contributing to efforts aimed at mitigating climate change. Additionally, it can generate carbon credits for organizations involved in carbon offset programs.

Fuel

Feature: High Calorific Value

Application: Alternative Fuel

Palm kernel shell charcoal’s high calorific value makes it an excellent alternative fuel source. It can be used in various industries for heat generation and energy production.

Soil Improvement

Feature: rich Micro-elements and Slightly Alkaline Property

Application: Soil Improvement and Soil Remediation

Palm kernel shell charcoal is rich in elements like N, P, Ca, Zn, and Mn, beneficial for soil enhancement. It can enrich soil with essential nutrients and adjust its pH, improving soil fertility and better crop yields.

Related Products

Making Equipment

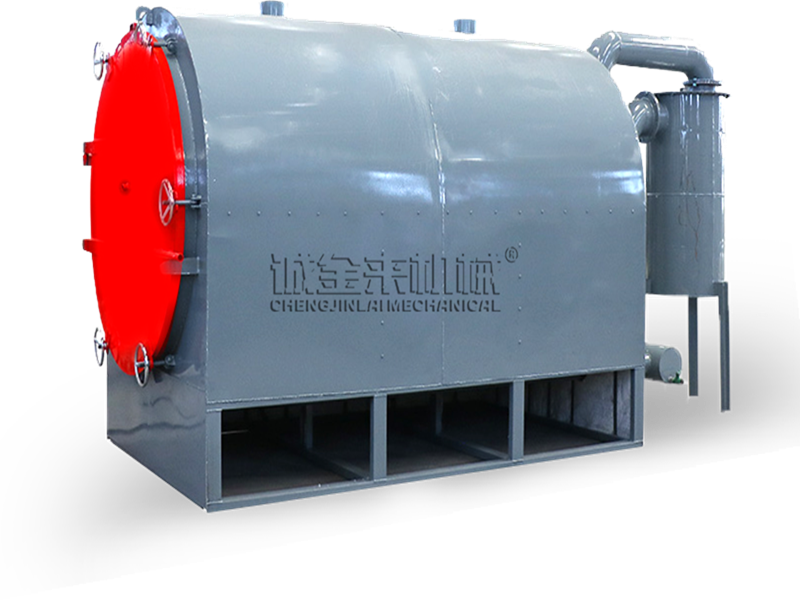

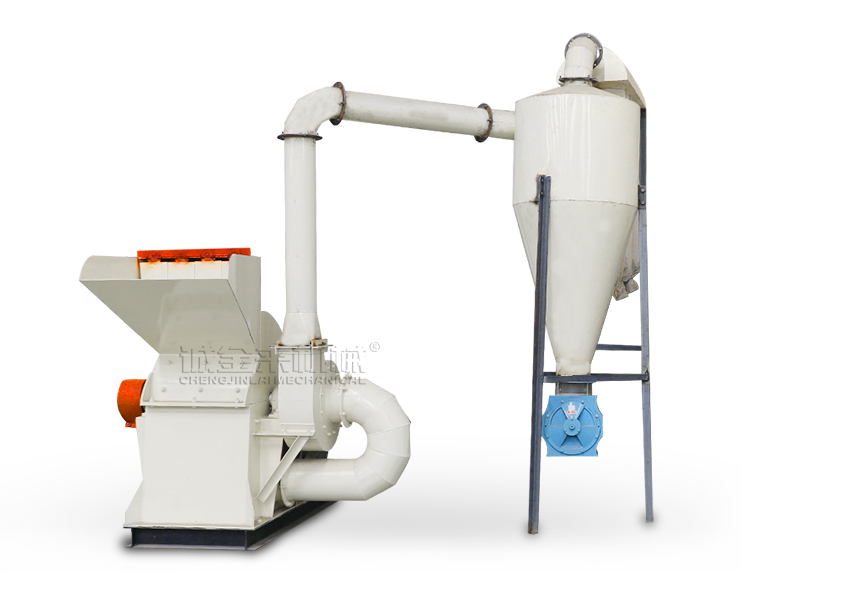

Types of Palm Kernel Shell Charcoal Making Machine for Sale

Better carbonization effect, higher carbonization rate 304 stainless material for inner furnace. High temperature resistance.

Higher Fixed carbon content.

Suitable for large materials such as wood logs.

Simple structure,easy to operate and maintain controllable and adjustable

carbonization temperature.

Smoke-free and dust-free, environmentally friendly. Easy to operate, saves time and labour. Excellent carbonization rate,without destroying the shape structure.

Wechat

Wechat

+8613838093177

+8613838093177