Are you looking for rice husk charcoal making machine for sale? Please have a look at Weiwa Group! We can provide the most suitable solution and machine for you. Come and follow us to learn about the machine here.

What is Rice Husk Charcoal Making Machine?

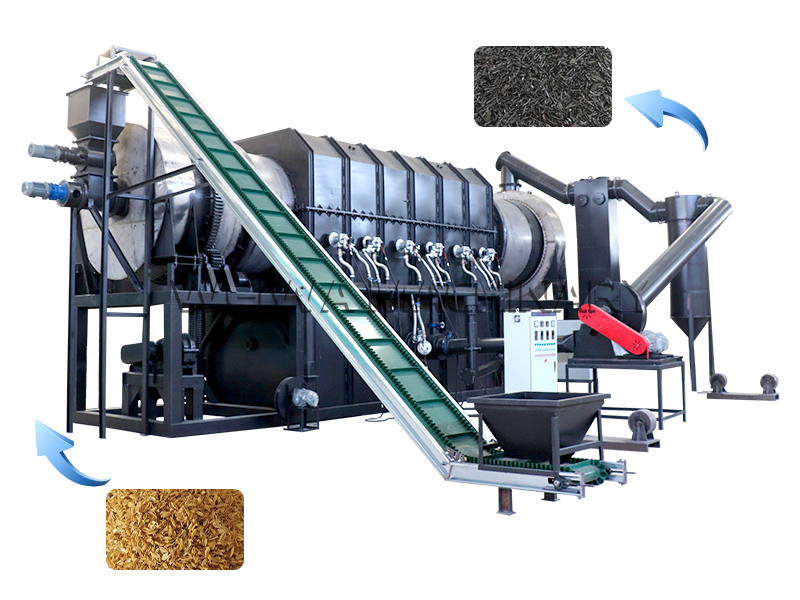

A rice husk charcoal making machine transforms agricultural waste (rice husk) into biochar through high-temperature carbonization. This eco-friendly process reduces waste and creates renewable energy. With millions of tons of rice husk discarded annually, traditional disposal methods like burning or landfills harm the environment. Rice husk charcoal making machines offer a sustainable solution by converting waste into valuable products.

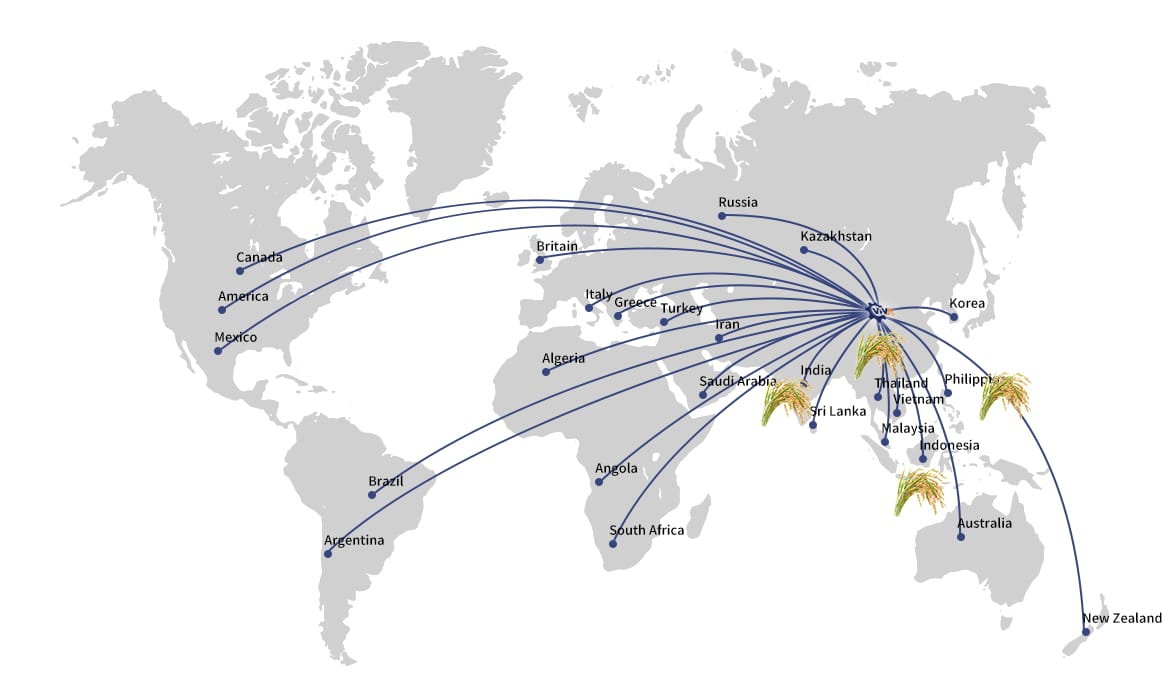

Background of Rice Production Industry

Here are the top countries in the world for rice production per acre in 2024:

Rice Husk Disposal Current Challenges

Low Recycling Rate

Approximately 150 million tons of rice husk are generated worldwide each year. However, the recycling rate of rice husk is less than 25%. The lack of an effective recycling system and infrastructure is the main reason. As a result, rice husk is often abandoned or not fully utilized.

Immature Technology

Currently, available rice husk processing technologies are inefficient. For example, incineration for energy or simple composting cannot fully tap the potential value of rice husk. More advanced processing technologies, such as biomass carbonization, have not yet been widely used.

Economic Feasibility Issues

Large-scale recycling of rice husk often involves high third-party costs. They include collection, transportation and processing fees. These costs may be too high for rice growers and processing plants. As a result, economic feasibility reasons hinder practitioners from recycling.

Sustainable Solution: Rice Husk Charcoal Making Machine

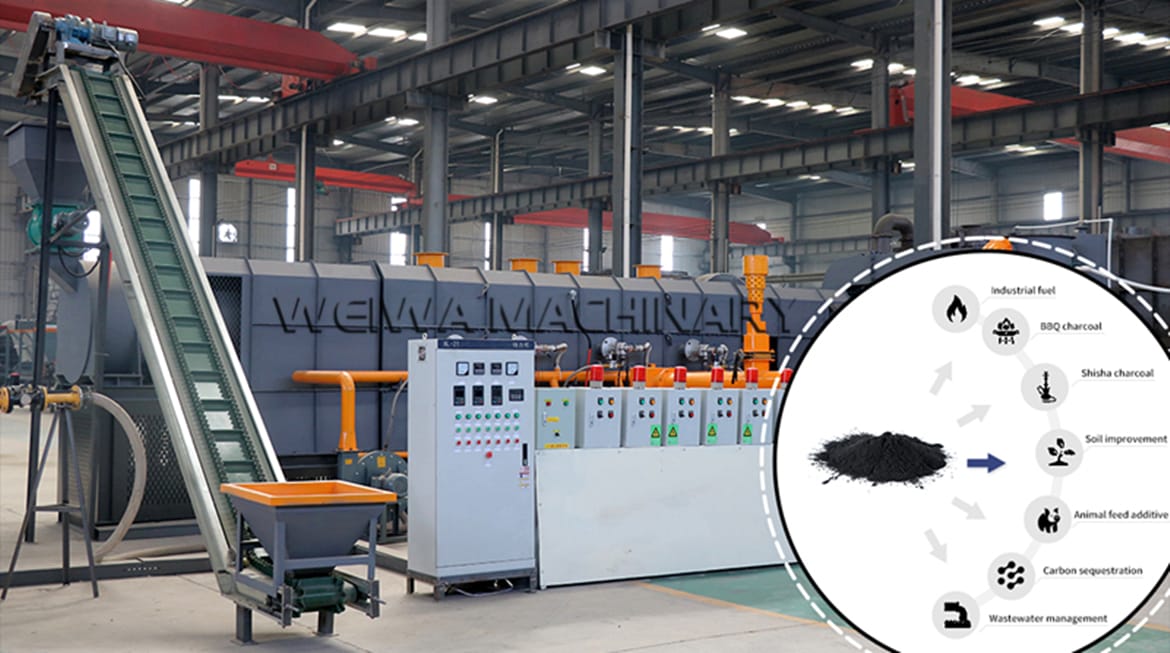

-1.jpg)

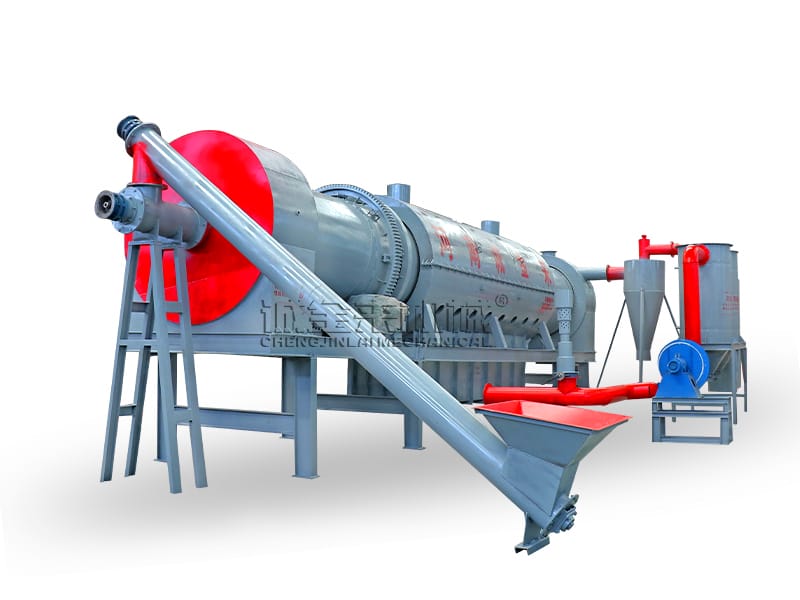

Rice husk charcoal making machine is the current mainstream agricultural waste recycling solution. It is favored by recyclers for its environmental friendliness and high efficiency. The machine achieves rice husk reduction and resource utilization.

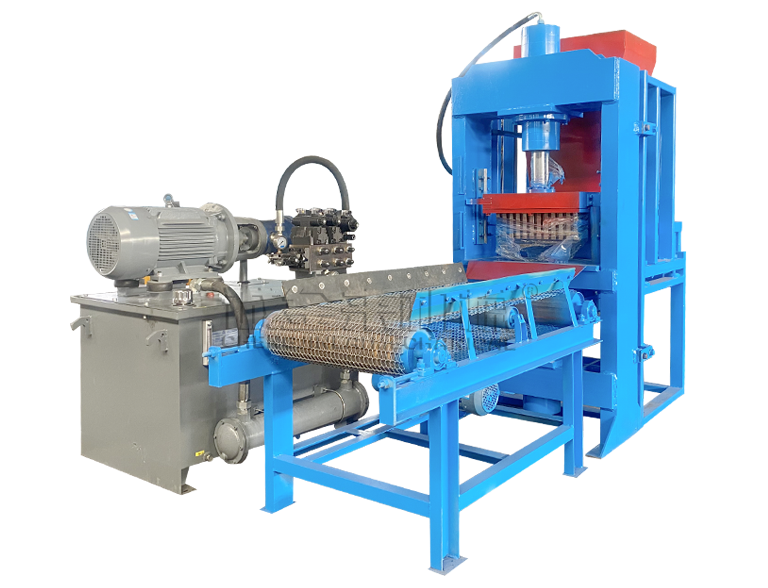

By using rice husk charcoal making machine, we can get the most important end product, rice husk charcoal. The charcoal can be further processed into industrial hookah or barbecue charcoal, both of which have high values and can be applied in many areas. It is the most suitable machine for the hookah charcoal or BBQ charcoal production.

hookah charcoal

BBQ charcoal

How to Use the Rice Husk Charcoal Making Machine?

Features of Rice Husk Charcoal Making Machine

Equipped with Alarm Device

The PLC electric cabinet has an alarm device, and there will be an alarm display and an alarm for some electrical failures.

With Explosion-proof Water Seal

There is an explosion-proof water seal at the combustible pipeline (to prevent abnormal pressure of combustible gas in the equipment)

Variable Frequency Fan Guide

The direction of the gas in all pipelines is led by the fan (the fan is variable frequency), and it will be displayed on the PLC when the pipeline is blocked.

High Heat Efficiency

The material is not in contact with the flue gas and is not polluted by hot air.

Good Energy-saving Effect

The heat utilization rate of this equipment is higher, the use of air heat ex-changer can effectively improve the thermal efficiency by 5-10%, and the energy saving effect is good.

Get Benefits from Rice Husk Charcoal Machine

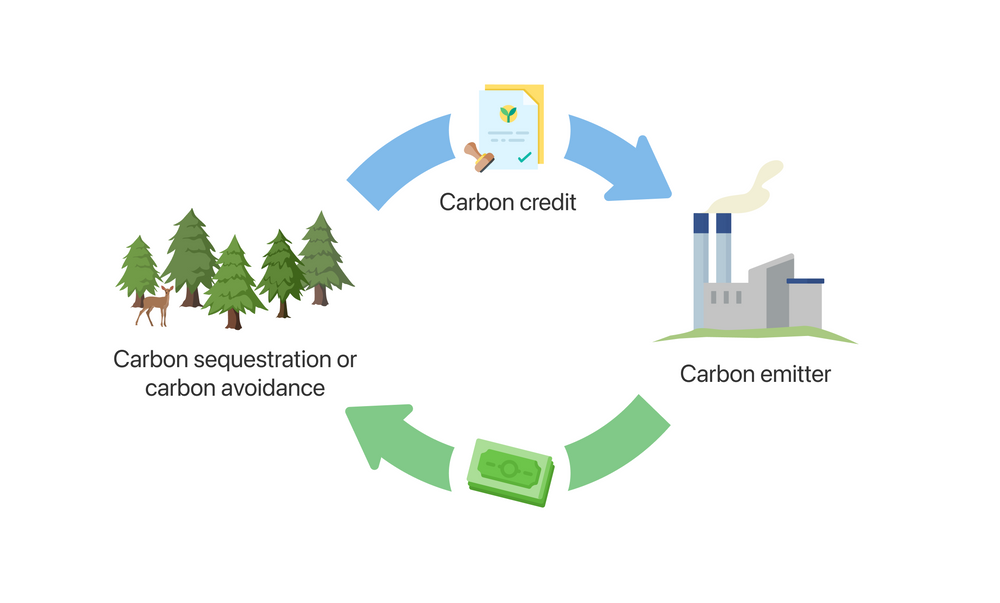

Guaranteed Access to Carbon Credit Trading

The biochar produced after the Rice Husk is treated by a continuous carbonization furnace has a stable carbon structure and can be stored in the soil for hundreds of years, reducing carbon dioxide in the atmosphere. This process is in line with the category of “carbon removal” or “carbon sequestration” in the carbon credit project, and can be applied for carbon credits through international certifications (such as VCS, GS, etc.)

High-Quality Rice Husk Charcoal Output

Our carbonization process uses high-temperature carbonization, guaranteeing the production of biochar that meets EBC standards. The product’s H/C molar ratio, heavy metal content, and PAHs levels align with the requirements for a variety of EBC application scenarios, ensuring superior biochar quality for diverse uses.

Soil Improvement

- 80% microporous structure to improve soil aeration and drainage

- Provide some trace elements, such as potassium, magnesium, zinc

- Alkalinity and ion exchange helps adjust soil pH and save on fertilizer costs

Related Products

Different Types of Carbonization Equipment

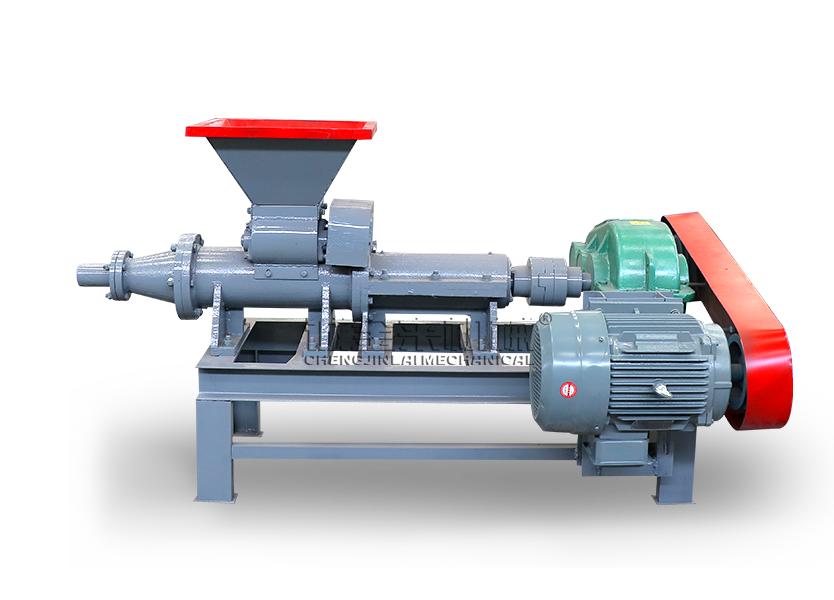

Better carbonization effect, higher carbonization rate 304 stainless material for inner furnace. High temperature resistance.

Higher Fixed carbon content.

Suitable for large materials such as wood logs.

Simple structure,easy to operate and maintain controllable and adjustable

carbonization temperature

Wechat

Wechat