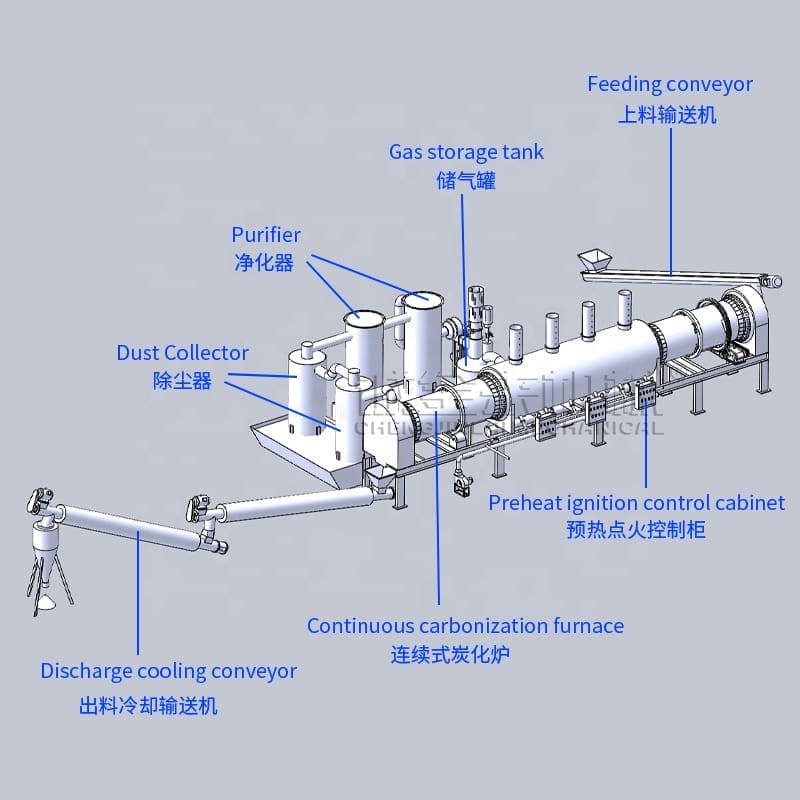

We are a professional biochar making machine manufacturer, our biochar production equipment is also called drum type continuous carbonization furnace. It is suitable for large scale continuous biochar production. Our biochar making machine uses pyrolysis technology to perform anoxic dry distillation and carbonization of wood, fruit shells, rice husks, garbage, sludge, oil sludge, animal feces, leather and other materials under high temperature conditions in the furnace, and it is an environmentally friendly continuous carbonization equipment with high output.

Biochar Production Process

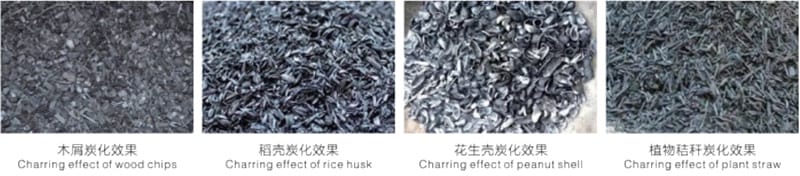

Carbon-containing lignin raw materials such as wood, rice husks, peanut shells, plant straw, and bark are first crushed by a hammer mill (the particle size is required to be less than 5mm), then put into a dryer for drying or naturally dried in the sun (the moisture content is required to be less than 20%), and then go through drying, drying, carbonization, cooling and other processes in a drum carbonization furnace to turn the loose raw materials into the required charcoal.

Grain powder→Pulverizer→Conveyor→Tumble dryer→conveyor→Drum type continuous carbonizing furnace

It is necessary to process large pieces or long-fiber raw materials into particles or powders suitable for carbonization. The raw materials can be crop straw, wood chips, rice husks, coconut shells, bamboo chips, etc.

Pulverizer

Function: crush larger particles of raw materials into fine particles to improve the subsequent carbonization efficiency.

Conveyor

Function: used to transport the crushed materials to the next process, such as drying or carbonization.

Tumble Dryer

Function: reduce the moisture content of the material and improve the carbonization efficiency. Suitable for raw materials with high humidity, such as wood chips, sawdust, straw powder, etc.

Conveyor

Function: transport the dried materials to the carbonization furnace to ensure continuous production. Usually high-temperature resistant conveying equipment is used.

Drum Type Continuous Carbonizing Furnace

Function: carbonize organic materials at high temperature in an oxygen-deficient environment to generate biochar. It has the characteristics of continuous feeding and discharging, which improves production efficiency.

The rotary carbonization furnace is equipped with biomass gasification furnace, flue gas purifier, fan, self-distributed gas burner, carbonization furnace and other equipment.

Rotary Contnous Carbonization Furnace Working Process

The continuous carbonization furnace adopts the dry distillation carbonization method, making full use of the combustible gases such as carbon monoxide, methane, hydrogen, etc. produced in the carbonization process. The wood tar and wood acid liquid are separated through the flue gas purification system to obtain pure combustible gas, which is then fully burned through the self-matching air burner to heat the high-temperature carbonization pipeline (the temperature is generally controlled at around 600°C).

Step 1: Initial Heating & Gas Treatment

Material is heated in the gasification furnace, producing flue gas.

A flue gas purification system treats the smoke, converting it into pure combustible gas.

Step 2: Gas Combustion & Temperature Rise

The purified gas flows to the combustion chamber via an induced draft fan.

High-temperature combustion begins once gas ignites, heating the rotary carbonization furnace to required levels.

Step 3: Material Carbonization

Raw material enters the rotary carbonization furnace through a feeder.

Drying and carbonization occur sequentially inside the rotating chamber.

Step 4: Flue Gas Recycling

New flue gas from carbonization is purified again.

This gas returns to the combustion chamber as a self-sustaining heat source.

Step 5: Final Cooling & Output

Carbonized material moves to a cooling discharge machine.

Finished charcoal is cooled continuously and collected for packaging.

Biochar Production Equipment Parameter

| Continuous Carbonization Furnace | Tumble Dryer | Conveyor | |||

| Pipe Diameter(mm) | 1000×1500 | Water evaporation rate | 100(kg/h) | Materil | Stainless Steel |

| Capacity(kg/h) | 500-600 | ||||

| Carbonized pipe temperature(℃) | 500-800 | ||||

| Furnace temperature(℃) | 350-850 | ||||

| Cooling carbon extractor(kw) | 3 | Speed | 10 (r/min) | Width | Customize |

| Screw feeder(kw) | 4 | ||||

| Main engine of carbonizer(kw) | 5.5 | ||||

| Distribute fan(kw) | 3 | ||||

| Fan(kw) | 11 | Power | 45kw | Height | Customize |

| Auxiliary burner | 1 | ||||

| Main burner | 1 | ||||

| Liquefied gas burner(set) | 6 | ||||

Biochar Making Machine Features

High-Efficiency Continuous Carbonization

Adopts an advanced drum-type continuous carbonization furnace for uninterrupted biochar production.

Energy-Saving and Eco-Friendly Design

Equipped with a gas recycling system to reuse combustible gases, reducing fuel consumption.

Versatile Raw Material Adaptability

Compatible with various biomass feedstocks, such as wood chips, coconut shells, rice husks, sawdust, and straw.

Integrated Drying and Carbonization Process

Includes a tumble dryer to reduce raw material moisture content before carbonization.

Robust and Durable Construction

Built with high-quality alloy steel and refractory materials for longevity.

Biochar Machine Benefits

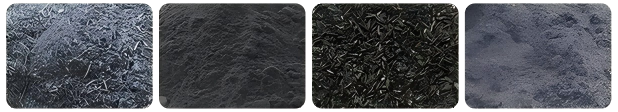

High-Quality Biochar Production

Produces premium-grade biochar with high carbon content and porosity.

Ideal for soil improvement, water filtration, and carbon sequestration.

Increased Business Profitability

Enables continuous and scalable production for higher revenue potential.

Reduces dependency on fossil fuels through energy-efficient operations.

Support for Circular Economy

Converts agricultural and forestry waste into valuable biochar products.

Contributes to sustainable agricultural and industrial applications.

Investing in Biochar Making Production Equipment ensures a high-efficiency, cost-effective, and environmentally friendly biochar production process. With its automated system, energy-saving design, and large-scale production capacity, this equipment is the ideal solution for businesses looking to expand into sustainable biochar production.

Take the next step towards profitability and sustainability—contact us today to get a quote or request a detailed product demonstration!

Wechat

Wechat

+8613838093177

+8613838093177