Stop letting valuable bagasse go to waste! Our cutting-edge Sugarcane Bagasse Charcoal Making Machine converts this abundant byproduct into high-margin sustainable products with unmatched efficiency. Join the green energy revolution while boosting your profits! WEIWA Group provides customers with first-class solution design, installation guidance and other after-sales services.

Background of Sugarcane Industry

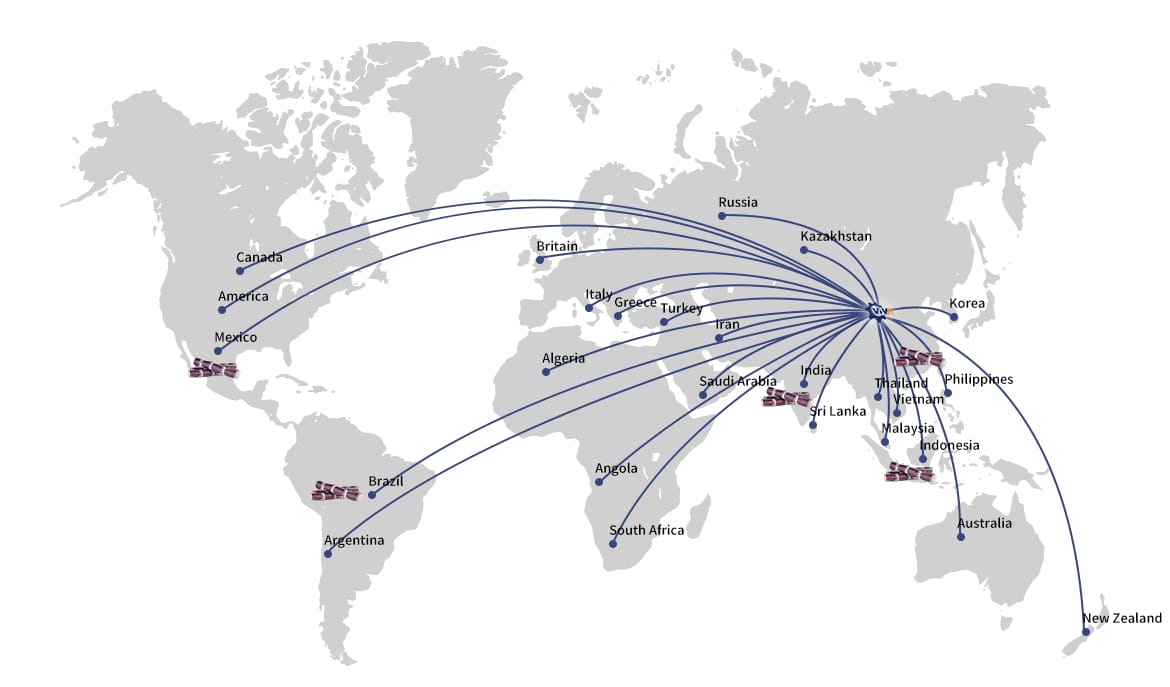

Sugarcane bagasse, a byproduct of sugarcane processing, is abundantly available worldwide. Large areas of sugarcane are planted in many countries, such as Brazil, India, Thailand, Pakistan, Mexico, Indonesia and so on.

Who Needs Sugarcane Bagasse Charcoal Making Machine?

- Sugar mills – Profit from bagasse waste

- Charcoal producers – Expand product range

- Farmers – Make biochar for soil improvement

- Waste-to-energy companies – Sustainable fuel production

New solutions:Sugarcane Bagasse Charcoal Making Machine

From the harvest to the final processing, the resulting sugarcane waste which is suitable for charcoal production mainly includes:

Sugarcane leaves: Sugarcane leaves are a waste product usually produced during harvest.

Sugarcane tops: They represent 15 to 25% of the aerial part of the plant. They generally consist of green leaves, bundle sheaths, and variable amounts of immature cane.

Sugarcane bagasse (straw): Bagasse is the fibrous material that remains after the extraction of sugar juice and constitutes about 30–40 wt % of the sugarcane. Around 280 kg of bagasse is generated from every ton of sugarcane.

Why Sugarcane Bagasse is Suitable for Making Charcoal?

The feasibility of converting sugarcane bagasse into bio charcoal is promising, supported by raw material characteristics and market trends.

Raw Material Analysis: Sugarcane Waste’s Natural Characteristics

- Abundance: Bagasse is a readily available waste product from sugarcane processing, ensuring a consistent and ample supply for charcoal production.

- Renewability: Bagasse is a renewable resource since sugarcane is a fast-growing crop that is harvested annually. This makes sugarcane charcoal a sustainable alternative fuel.

- High energy content: Bagasse’s high cellulose (45%), hemicellulose (32%), lignin (17%) content, and low ash content contribute to its high energy content, making it suitable for conversion into high-quality charcoal.

Market Analysis: Growing Interest in Biochar

- Rising popularity for bio-energy: Bioenergy is renewable energy made from biological materials. It has little environmental pollution during combustion. With the growing emphasis on environmental protection and sustainable development, bioenergy is becoming an increasingly popular alternative energy source. This drives the demand for bio charcoal such as sugarcane charcoal and wood charcoal.

- Cross-industry applications of biochar: Various industries are exploring the applications of biochar within their domains. For instance, in agriculture, biochar is used to enhance soil quality, while in livestock farming, it serves as a feed supplement. Industries, agriculture, livestock farming, etc. are all showing interest in the eco-friendly and sustainable properties of biochar.

How to Use Sugarcane Bagasse Charcoal Making Machine?

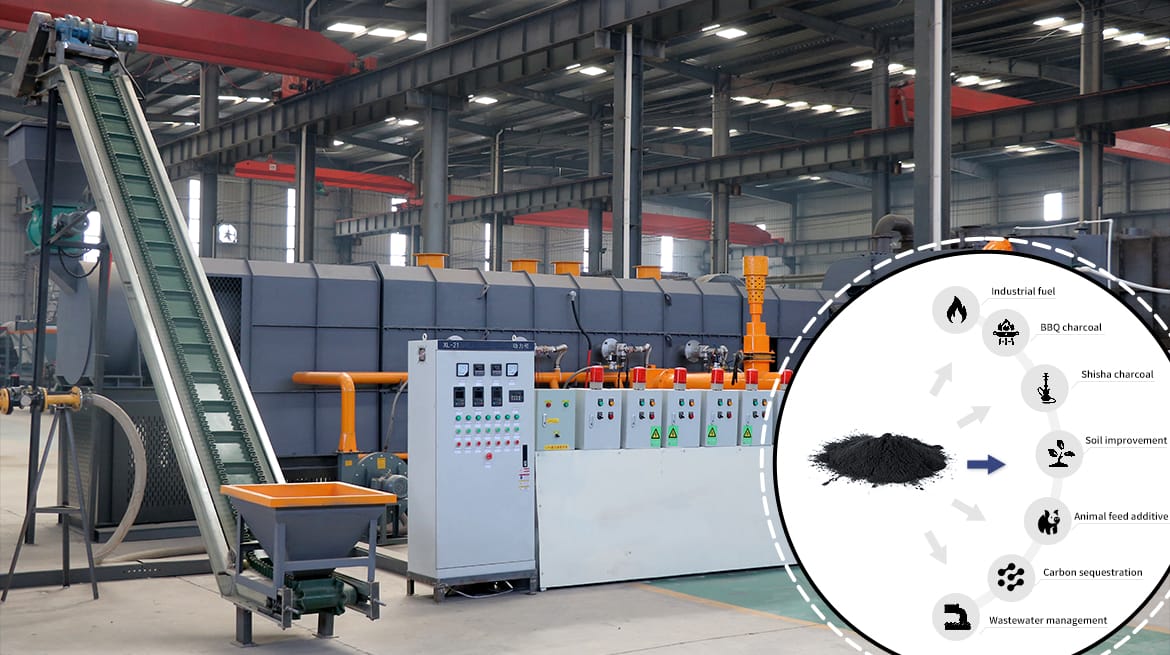

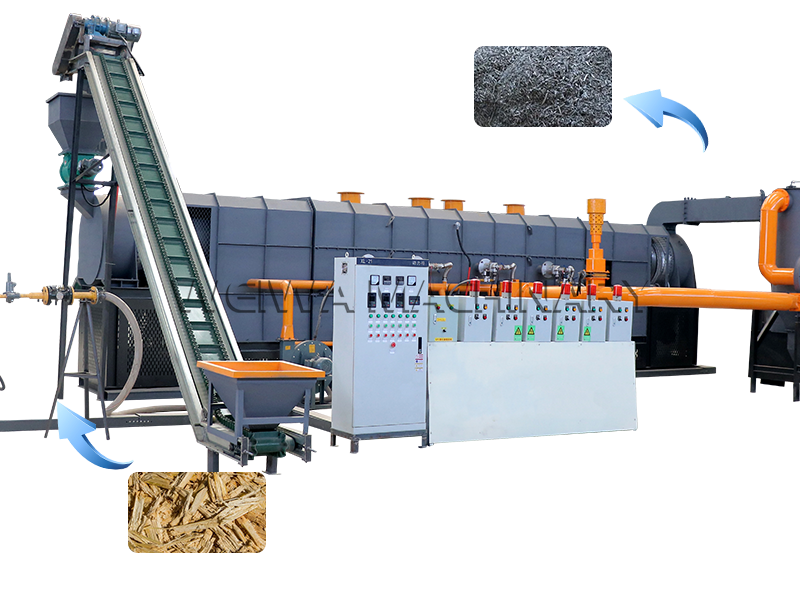

After acquiring the sugarcane charcoal making machine, you’re ready to commence the charcoal production process from the sugarcane bagasse. The sugarcane bagasse charcoal machine primarily operates on the principle of high-temperature carbonization. Here’s how it transforms sugarcane waste into charcoal:

01 Preprocessing

- Crushing (optional): The crushing system processes Sugarcane Bagasse into target sizes (less than 20mm).

- Drying (optional): The drying system processes the Sugarcane Bagasse to a moisture content of less than 15%.

02 Carbonization

- Feeding: The Sugarcane Bagasse is automatically fed into the furnace via a conveyor belt, screw feeder or Z-Belt.

- Carbonization: After heating the main furnace, the temperature gradually rises. The initial temperature helps dry out some of the moisture in the Sugarcane Bagasse. When the temperature reaches 250 degrees Celsius, demethylation begins. Combustible gas starts to generate. At 280 degrees Celsius, the exothermic reaction begins. The hydrocarbon molecules split into smaller carbon molecules and hydrogen. charcoal begins to be produced. As the temperature hits 450 degrees Celsius, aromatic ring compounds begin reacting.

03 Discharging

- Sugarcane Charcoal : Through a three-stage water-cooling discharger, Sugarcane Charcoal below 45 degrees Celsius is collected.

- Tar & wood vinegar collection (optional): Via the condenser, tar (biomass oil) and wood vinegar separate out and are collected separately.

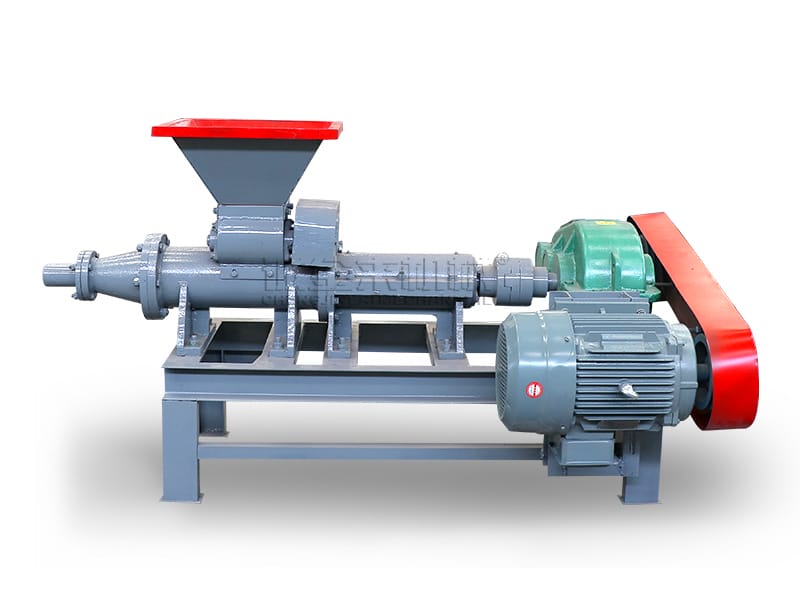

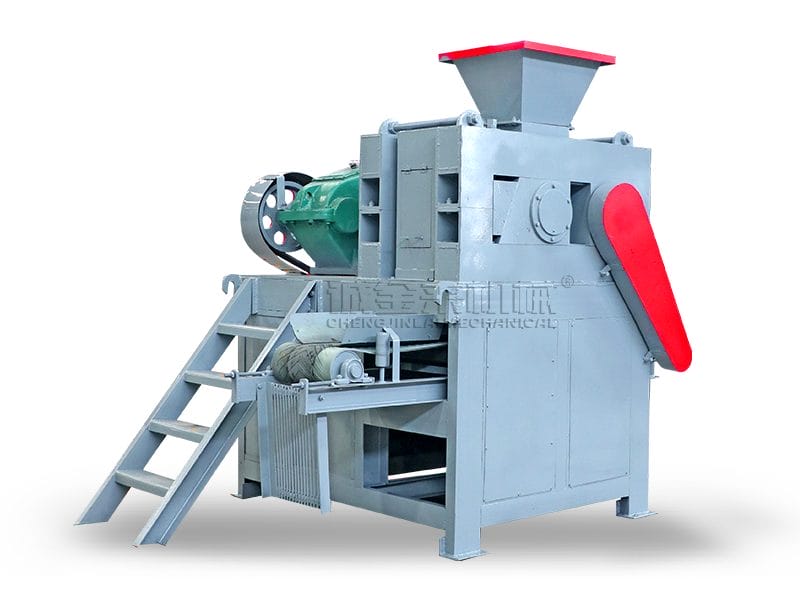

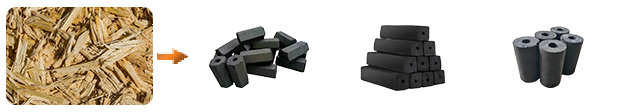

- Sugarcane Charcoal briquette making (optional): After being processed by the Sugarcane Charcoal briquette machine, the original shape of charcoal can be made into the required shape, such as round, square, stick, etc.

04 Combustible Gas Recovery

- After condensation and sulfur removal treatment, combustible gas can be recovered and reused.

- We can also introduce the excess heat from the carbonization furnace into the dryer to recycle the combustible gas, thereby saving fuel for the dryer.

05 Exhaust Gas Treatment

- The emission gas is treated by a spray tower, water curtain de-dusting tower, and cooling tower. The processed emission gas meets the EU emission standards.

- Weiwa Group provides high-standard customized exhaust gas treatment system.

Features of Sugarcane Charcoal Making Machine

Equipped with Alarm Device

The PLC electric cabinet has an alarm device, and there will be an alarm display and an alarm for some electrical failures.

With Explosion-proof Water Seal

There is an explosion-proof water seal at the combustible pipeline (to prevent abnormal pressure of combustible gas in the equipment)

Variable Frequency Fan Guide

The direction of the gas in all pipelines is led by the fan (the fan is variable frequency), and it will be displayed on the PLC when the pipeline is blocked.

High Heat Efficiency

The material is not in contact with the flue gas and is not polluted by hot air.

Good Energy-saving Effect

The heat utilization rate of this equipment is higher, the use of air heat ex-changer can effectively improve the thermal efficiency by 5-10%, and the energy saving effect is good.

How to Make Profit from Sugarcane Bagasse Charcoal Making Machine?

The produced sugarcane bagasse charcoal briquettes can bring good economic benefits because of their wide application across different industries. Investors can sell them to the relevant industries for profit.

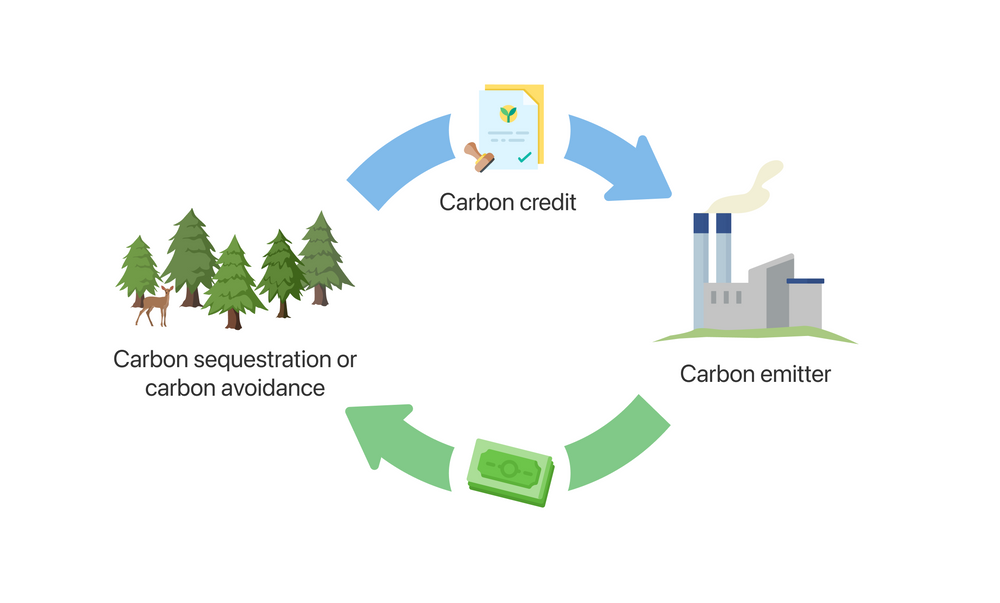

Guaranteed Access to Carbon Credit Trading

- High carbon content

- 100% Natural and environmentally friendly

- Trap large amounts of carbon dioxide and Improve carbon footprint

- Be used for market transactions, such as carbon credits, carbon offsets

High-Quality Sugarcane Charcoal Output

By using Sugarcane Bagasse Charcoal Making Machine, we can get the most important end product, Sugarcane Bagasse Charcoal. The charcoal can be further processed into hookah or barbecue charcoal, both of which have high values and can be applied in many areas. It is the most suitable machine for the hookah charcoal or BBQ charcoal production.

Barbecue Charcoal

- High carbon calories

- Low smoke

- Low ash content

- Long burning time

- Fruity wood aroma

Hookah Charcoal /Shisha Charcoal

- Stable temperature

- High hardness

- Low smoke volume

- Long burning time

- Fruity wood aroma

Soil Improvement

- 80% microporous structure to improve soil aeration and drainage

- Provide some trace elements, such as potassium, magnesium, zinc

- Alkalinity and ion exchange helps adjust soil pH and save on fertilizer costs

Policy subsidy application

Some countries or regions provide subsidies or tax incentives for the use of biomass energy, such as the EU’s “Green New Deal” or China’s renewable energy support policy.

Related Products

The Sugarcane Bagasse Charcoal Making Machine can also process different raw materials

Wechat

Wechat