What is Hoisting Carbonization Furnace?

Hoisting carbonization furnace is widely used in various fields of charcoal processing and production.It is an environmentally friendly and smokeless carbonization equipment and is one of the important equipment for charcoal making production.

Hoisting carbonization furnace is separated from the combustion chamber, and a movably installed carbonization liner is used. One furnace body is equipped with three carbonization liners to achieve continuous operation.

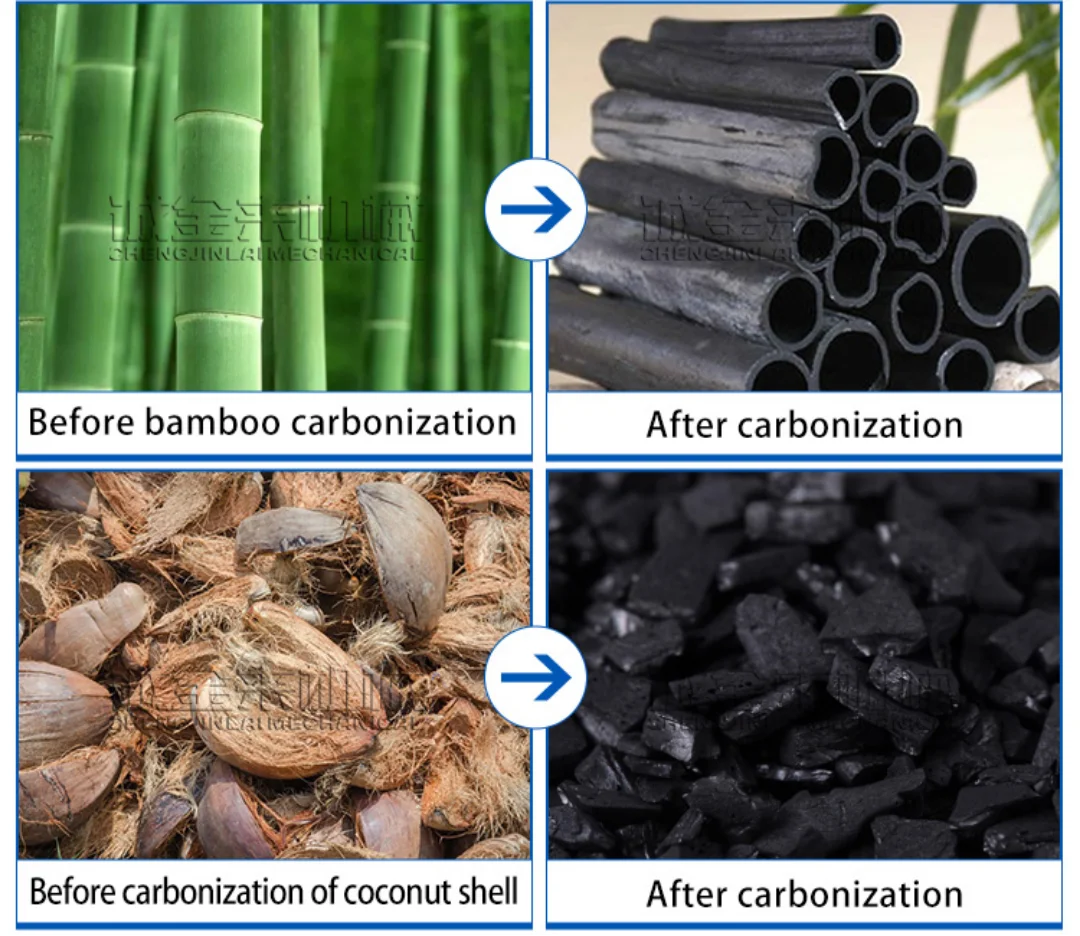

Hoisting carbonization furnace can carbonize the machine-made rods produced by the charcoal machine, and can also directly carbonize raw wood, wood blocks, tree bark, coconut shell, logs, wood blocks, tree bark and other raw materials.

Raw materials of hoisting carbonization furnace

The hoisting charcoal furnace is suitable for large pieces of material, such as logs, wood chunks, wooden furniture trimmings, biomass briquettes, coconut shells, twigs, etc. It is ideal for customers who want to obtain large pieces of charcoal. (If your raw material is less than 3cm, you can choose our continuous carbonization furnace.)

Basic Structure

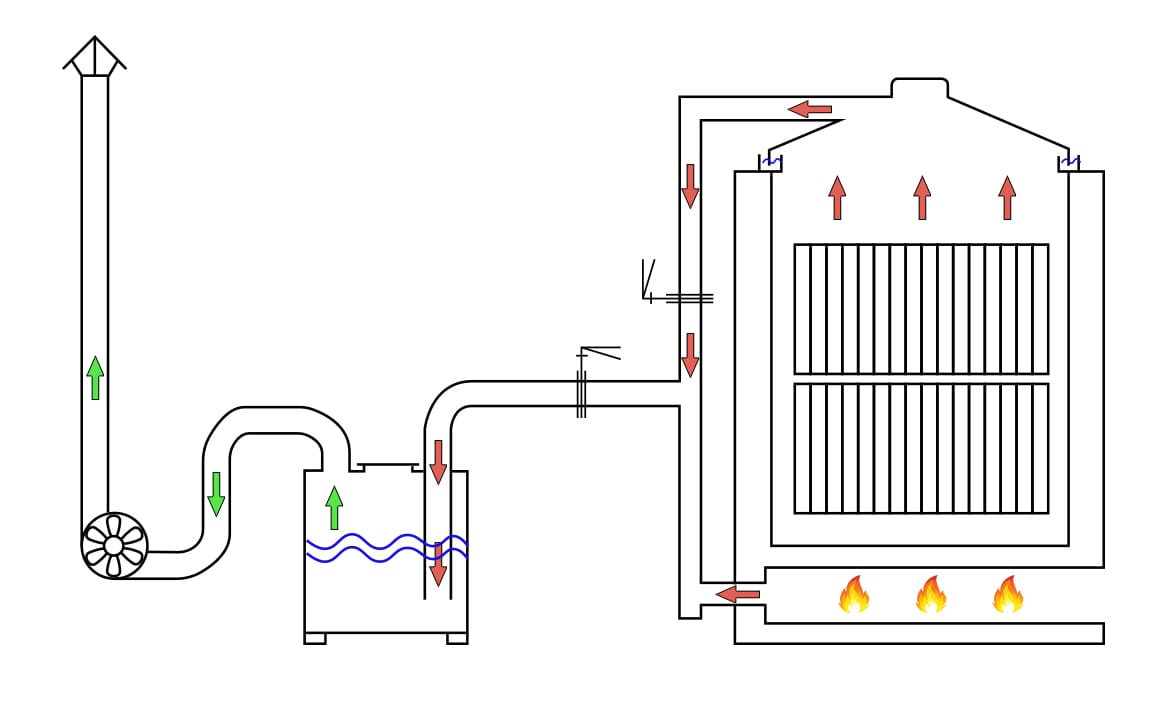

The main structure of the vertical carbonization furnace is the hanger, the outer tank, the inner furnace, the combustion chamber, the vent pipe for combustible gas circulation and the flue gas purification system. The inner furnace is the main carbonization chamber. The shell and inner liner of the charcoal making kiln are made of good quality steel, and the inner liner has a layer of refractory bricks and high-temperature resistant rubber.

One furnace body can be equipped with multiple charring inner stoves. No preheating treatment is needed when replacing the charring inner stove. The hanger of the charring furnace is very strong and has a good load-bearing capacity. Carbonization inner chamber The cooling of the chamber is completely separated from the furnace body, the structure of the equipment is simple and novel, and the operation is very easy.

Features

- (1)The three inner furnaces can be used cyclically, which can be continuous.

- (2)The inner furnace has a large volume, and can be loaded with 1.5 tons-2 tons of machine-made rods at a time.

- (3)The carbonization cycle is short, once every 8 hours, and the output is high.

- (4)The new five-stage purification device, leading the industry, can be environmentally friendly and smoke-free.

- (5)Combustible gas recovery device saves fuel.

- (6)There are various heat sources, such as wood, coal, and natural gas.

Working principle

When hoisting carbonization furnace is working, put the materials that need to be carbonized into the inner furnace and hoist them into the outer furnace; after sealing, conduct anaerobic heating and pyrolyze into combustible gas, tar and carbon through moisture removal;

The gas produced in the process passes through The flue gas purification device is used to achieve smokeless emission; the combustible gas is collected and burned at the bottom of the furnace body to be used as a subsequent heat source.

The details of the process for making charcoal by the airflow hoisting carbonization furnace:

Stage 1: drying process

After placing the inner stove which is of the biomass rods in the charcoal furnace, to ignite at the ignition port below the furnace, and the temperature in the furnace is gradually heated from normal temperature to about 100 °C. Because the temperature inside the furnace before ignition is low, this process should be heated with a large fire, reaching 100 degrees to the left, and then use a small fire to heat the carbonization temperature to 170 ° C – 200 ° C or so.

Stage 2: pyrolysis process

When the temperature in the carbonization furnace reaches 170 ° C – 200 ° C, use a simmer to heat the furnace temperature to about 340 ° C. The second phase takes about 2 hours and 30 minutes.

Stage 3: rapid pyrolysis process

When the temperature in the furnace reaches about 340 °C, use a small fire to heat the furnace temperature from 340 °C to 380 °C – 400 °C. The third phase takes about 2 hours.

Stage 4: the end of carbonization

When the temperature in the furnace reached about 400 ° C, there was no significant temperature change thereafter. Use a small fire to heat up, when the smoke output from the smoke outlet is significantly reduced and lightened, the flame is extinguished and the carbonization is over. The fourth phase takes about 40 minutes.

Stage 5: Charcoal cooling and discharging process

After the carbonization is completed, if no other cooling measures are taken, the fire can be sealed and the charcoal can be naturally cooled. There are two ways to seal fires: Method 1: seal the smoke outlet and cool the charcoal, and the surface of the charcoal briquettes is good. This method takes about 16 hours to cool down the charcoal. Method 2: completely open the smoke outlet and cool the charcoal. This process is the same as method 1, but the charcoal surface is not shiny like the former. This method takes about 16 hours for cooling. In these two ways, when the temperature in the furnace drops to about 40°C, to discharge the charcoal is ideal.

Core Components

- Hoisting device: national standard channel steel, electric hoist.

- Outer furnace and inner tank: thick steel plate, corrosion resistance, high temperature resistance.

- Insulation layer: high-aluminum insulation bricks with good insulation performance.

- New type of purification and flue gas recovery: thick steel plate, spray device inside, corrosion resistance and high temperature resistance.

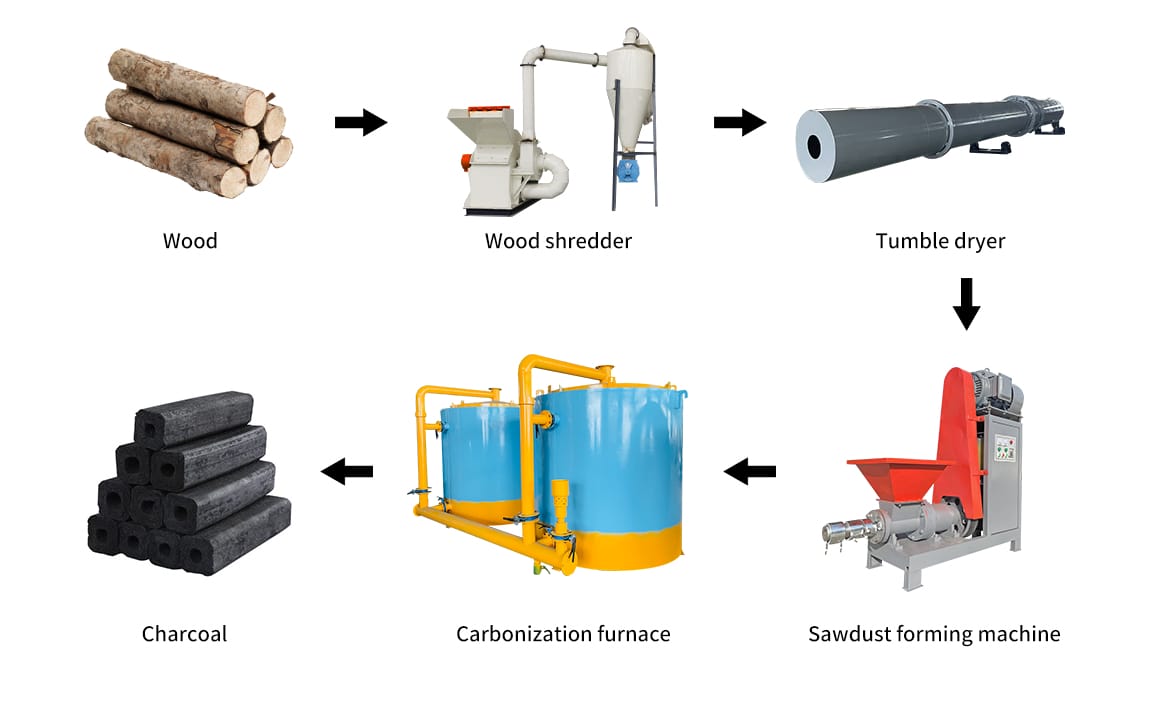

What is the Process of Hoisting Carbonization Furnace

Our professional team can provide you with free production line planning according to your requirements!

Packaging & Shipping

1. All the machines will be wrapped up with plastic film first.

2. The machine parts need to be put in a fixed container, should be fixed well, lest

collision and wear, or lost.

Starting Your Business Here!

Until now, we have customers more than 130 countries, Indonesia, India, Malaysia, Laos, Myanmar, Thailand,Vietnam,Philippines,Pakistan, Sri Lanka, Lebanon, Georgia, Turkey, Poland, Czech, Mongolia, South Korea, Romania, Egypt, Sudan,Tunis,Algeria, Ethiopia, Tanzania Equatorial Guinea, Zambia, Mexico, South Africa, etc.

You’re welcome if you’d like to visit our factory! You can contact us now!

Related Posts

Wechat

Wechat

+8613838093177

+8613838093177