Horizontal Carbonization Furnace for Wood is used to solve the waste wood disposal issues in the forestry and wood processing industry. Through high-temperature and low-oxygen carbonization technology, wood charcoal machine transforms waste wood into economically valuable charcoal. The entire transformation process ensures environmental friendliness and minimal pollution. As one of the leaders in the waste recycling field, Weiwa Group offers a one-stop wood recycling solution for your maximum convenience.

What is the operating instructions of Horizontal Carbonization Furnace for Wood?

Wood to charcoal machine is a kind of equipment specially used to convert wood into charcoal. It converts lignin, cellulose and other organic substances in wood into charcoal by high temperature carbonization. Modern machines adopt advanced design to improve production efficiency, reduce energy consumption and ensure long-term stable operation of equipment.

- 1,Horizontal charcoal furnace in the burning of log charcoal, the wood should be placed in the furnace in order first.

- 2,After the fire starts, as the temperature rises, continue to add fuel rods. Keep an eye on the temperature gauge and always remember to open the valve.

- 3,When the temperature reaches a certain point, combustible gases are produced, reducing the number of sticks added.

- 4,When the combustible gases have burned out, wait for the temperature to drop to about 50 degrees and open the door to collect the charcoal.

Optional Wood Charcoal Briquette Machine: Add Value with Ease

A wood charcoal briquette machine significantly enhances the value of briquette charcoal by transforming loose wood biochar powder into compact, energy-dense briquettes (rod, spherical, cubic, and hexagonal shapes, etc.). Here’s how it boosts the utility and value of charcoal:

Higher Energy Density

Briquetting charcoal increases its energy density, making it an efficient and longer-burning fuel. This characteristic makes charcoal briquettes popular for cooking, heating, and industrial uses, providing a cost-effective alternative to conventional fuels like coal or wood.

Compact Form and Easy Storage

Charcoal briquettes are compact and uniform, allowing for easier storage, transportation, and handling compared to loose bamboo charcoal. This consistency appeals to customers, especially in bulk, because it reduces wastage and facilitates efficient storage.

Higher Market Value

Briquetting adds significant commercial value to charcoal by creating a refined product that’s ready for diverse uses. Compared to raw bamboo charcoal, briquettes fetch a higher price in the market, especially with increasing demand for eco-friendly alternatives.

Why Wood is an Excellent Raw Material for Charcoal Production

Raw Material Properties

- Good Processability: Wood fiber structure is uniform and the texture is tight. Therefore, when cutting and crushing, wood can adapt to the requirements of different sizes while avoiding the generation of dust. In addition, wood can remove moisture in a shorter time, improving pyrolysis efficiency.

- Good Fluidity: The good fluidity of wood helps to ensure the smooth continuous feeding and avoid raw material blockage. In addition, good fluidity also ensures the uniform distribution of raw materials. Thus, this promotes uniform heating and conversion of the wood charcoal making machine.

Quality of Charcoal Product

- High Calorific Value: The high lignin content of wood forms a high density & strength carbon structure in the wood charcoal after pyrolysis. Thus, this improves the calorific value. In addition, the low ash content of wood increases the carbon content of the finished charcoal, further improving the calorific value.

- Excellent Pore Structure: Fiber structure is more easily converted into pores during making charcoal from wood. Thus, this enhances wood charcoal’s adsorption. In addition, pore characteristics increase specific surface area of charcoal. Thus, more oxygen can contact charcoal surface, promoting efficient combustion.

How to Use Horizontal Carbonization Furnace for Wood to Bring Good Economic Profit

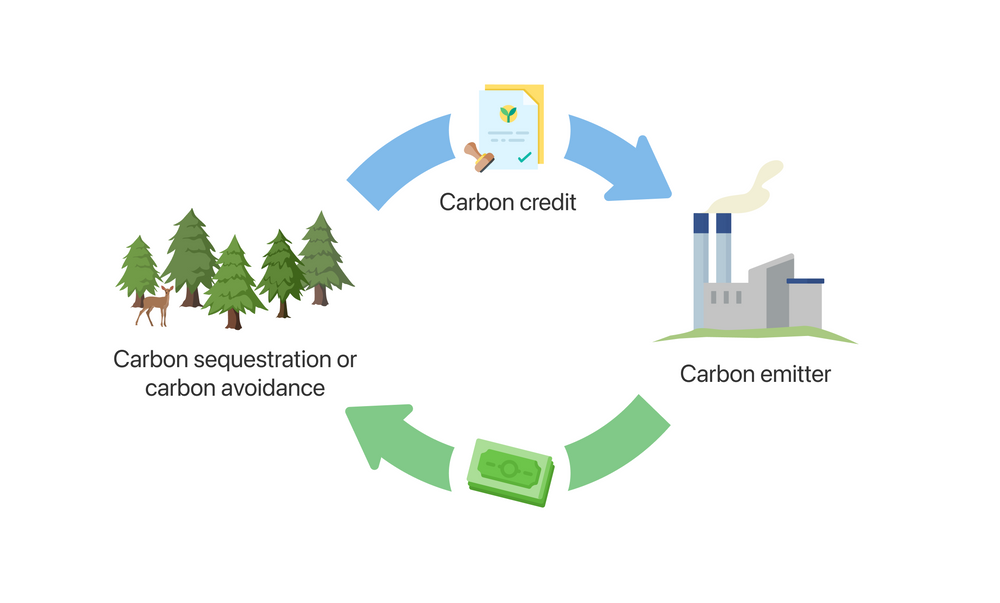

Carbon Sequestration

Wood biochar is rich in carbon and has a stable structure, allowing it to store carbon in the soil for many years. This long-term carbon sequestration helps reduce the harmful effects of carbon dioxide on the environment.

Heating Fuel & BBQ & Hookah

Wood charcoal has a fixed carbon content of over 80%, making its calorific value about 30% higher than wood charcoal. Therefore, it suits to be:

- used for BBQ or Hookah.

- used as fuel in cement plants, power factory, brick plants, etc.

Soil Improvement

Wood charcoal is a good material to improve soil quality. It can:

- improve soil aeration and drainage and enhance soil structure;

- increase nutrient retention and promote plants’ healthier growth and higher yields.

- regulate soil pH, etc.

Applications of the Horizontal Carbonization Furnace for Wood

Other types of carbonization furnaces, such as continuous carbonization furnaces and lifting carbonization furnace are important equipment for the production of charcoal.

Therefore, charcoal producers and charcoal processing plants should choose their own carbonization machines according to their actual production needs.

Continuous Carbonization Furnaces

Lifting Carbonization Furnace

Why do so many manufacturers choose Weiwa Horizontal Carbonization Furnace for Wood?

By summarizing the past data of seling, we can find that this horizontal carbonization furnace is popular with charcoal suppliers.Why? Because it has many advantages which can attract biochar manufacturers to invest in as follows:

Stocks

We have a lot of stocks,we can delivery quickly.

Cerificate

We have obtained many cerification,so you don’t need worry about the quality of our machine

Factory

We are factory,we can provide the same quality machine with a lower price.

Henan Weiwa Machinery Manufacturing Co., Ltd. is a professional manufacturer of charcoal manufacturing machinery in China. Continuous improvement and innovation is our production philosophy. Our tenet: Survive by quality, develop by credit, quality first, credit first, integrity-based, customer first.

Wechat

Wechat

+8613838093177

+8613838093177