Coconut shell charcoal making machine is an efficient machine for recycling waste coconut shells. When you plan to recycle these coconut shells, you require more than a simple equipment provider. You need a proficient expert capable of delivering the appropriate solution. Welcome to get the Carbonization solution from Weiwa Machinery Group.

Background of Coconut Industry

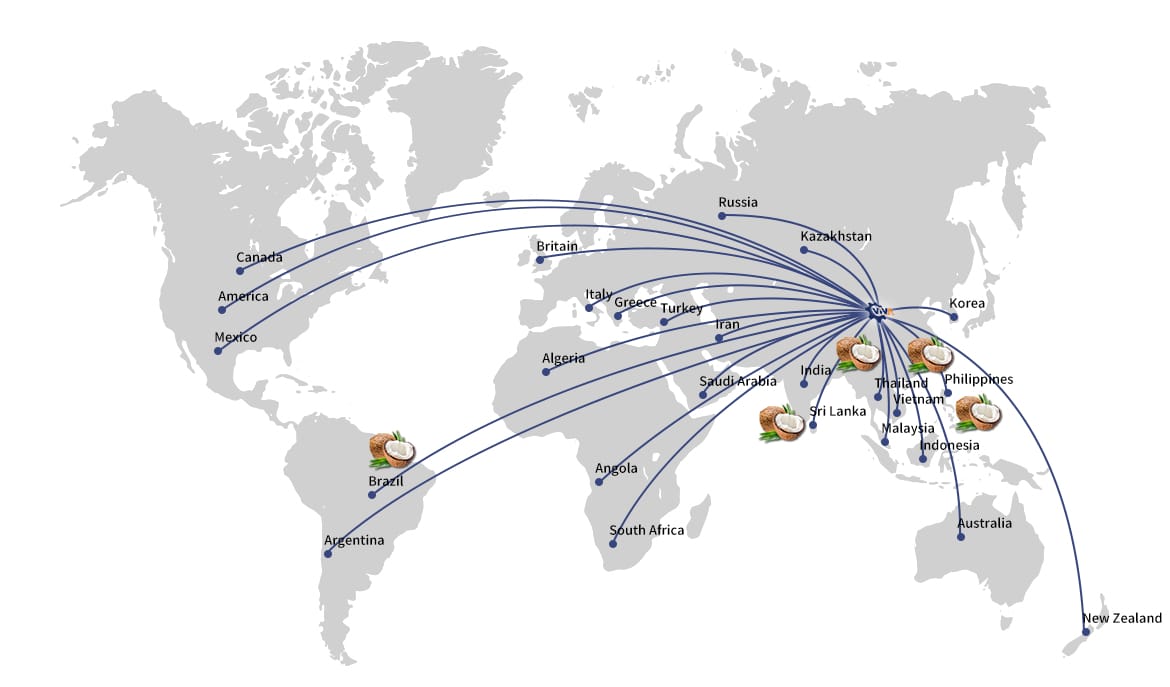

Production Countries

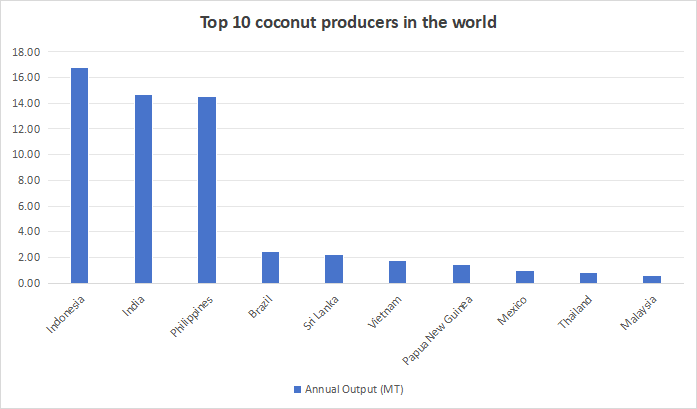

Coconut trees are grown in more than 80 countries. Here, we list the top 10 countries in coconut production. Indonesia, the Philippines and India are far ahead in coconut production among these countries. Coconut exports from these three countries account for 70% of global coconut exports. Please see the coconut production data.

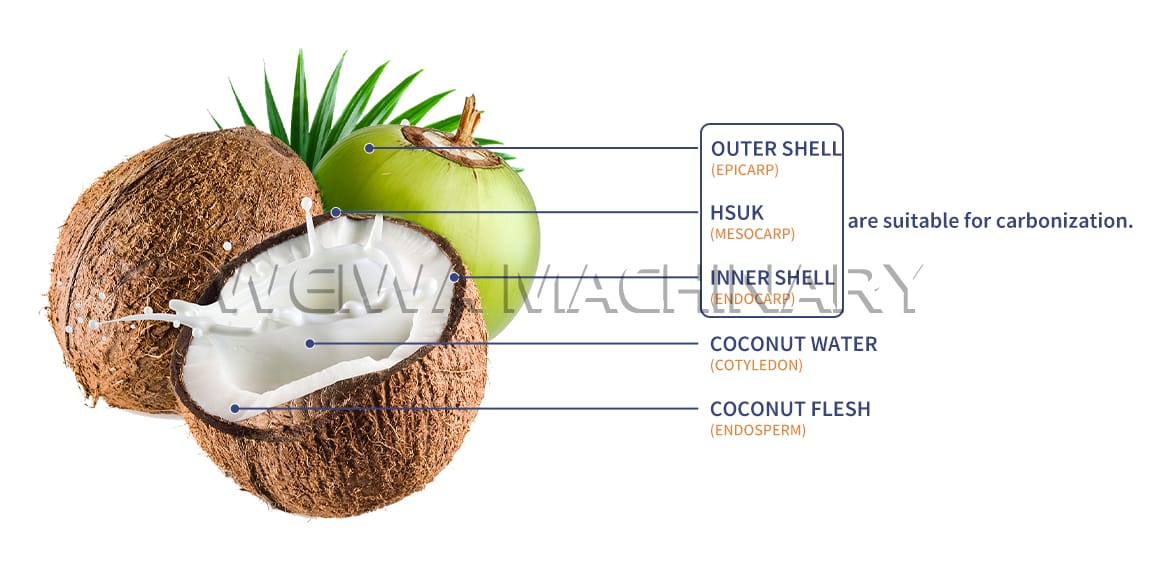

Coconut Shell Management

Among these kinds of coconut waste, coconut shell recycling by using Coconut Shell Charcoal Making Machine is the main solution Weiwa group offers. Approximately 50 million coconut shells are discarded every year. Landfill or discarding coconut shells produce greenhouse gases and pollutes the environment. Coconut shells is rich in cellulose, hemicellulose and lignin. It actually have a high energy value. This is a waste that needs to be recycled urgently.

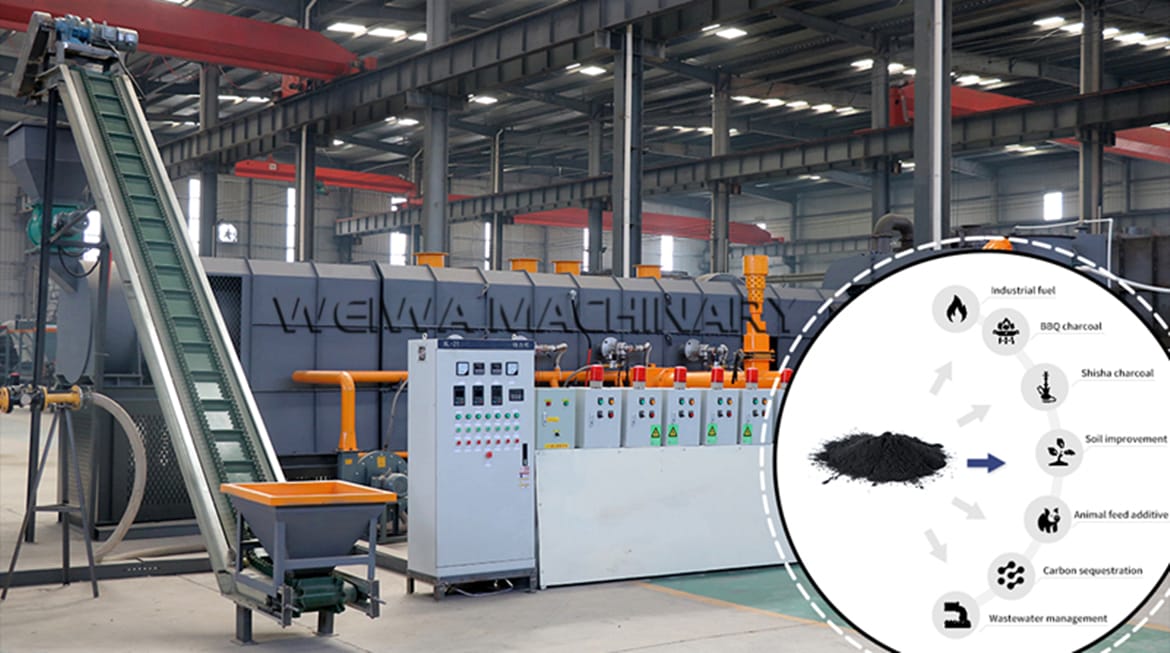

How to use Coconut Shell Charcoal Making Machine

The entire coconut shell recycling process mainly includes crushing, drying, feeding, carbonization, discharging, combustible gas recovery, exhaust gas treatment, and coconut shell briquette production.

01 Preprocessing

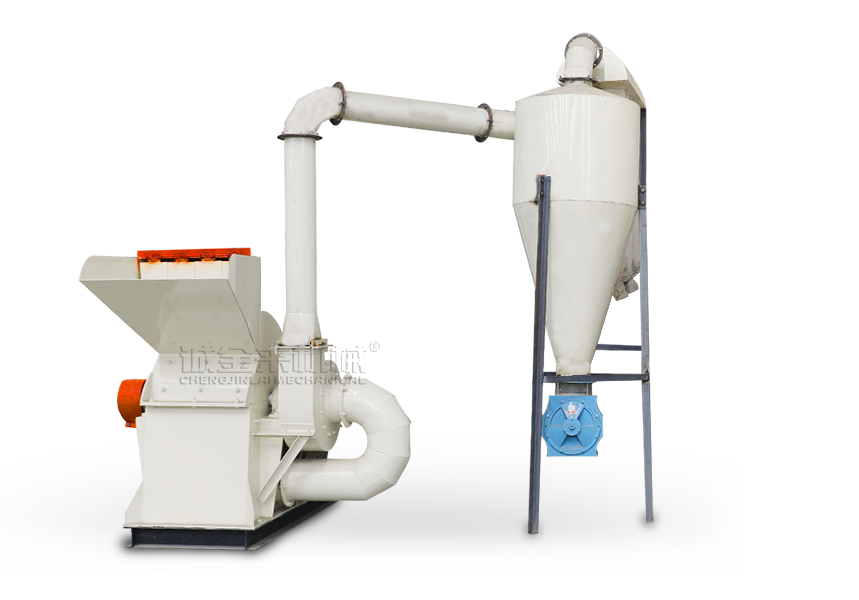

- Crushing (optional): The crushing system processes coconut shells into target sizes (less than 20mm).

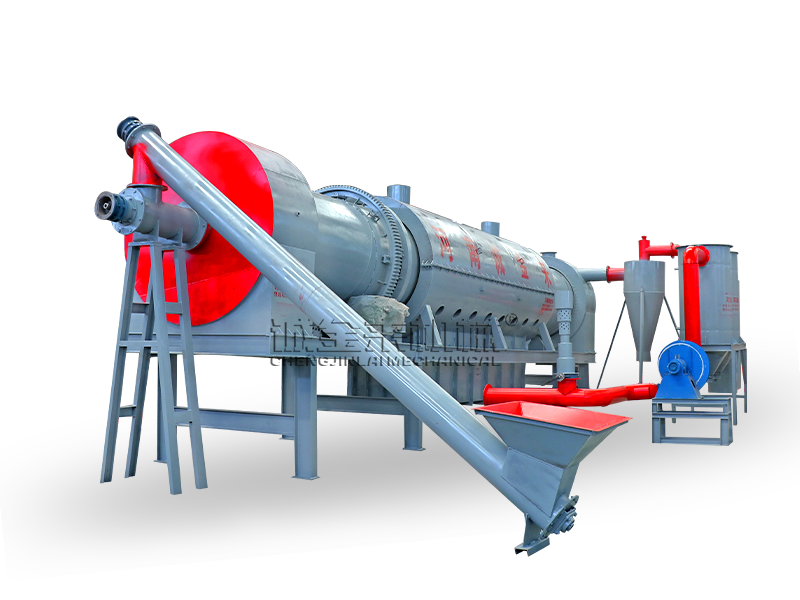

- Drying (optional): The drying system processes the coconut shell to a moisture content of less than 15%.

02 Carbonization

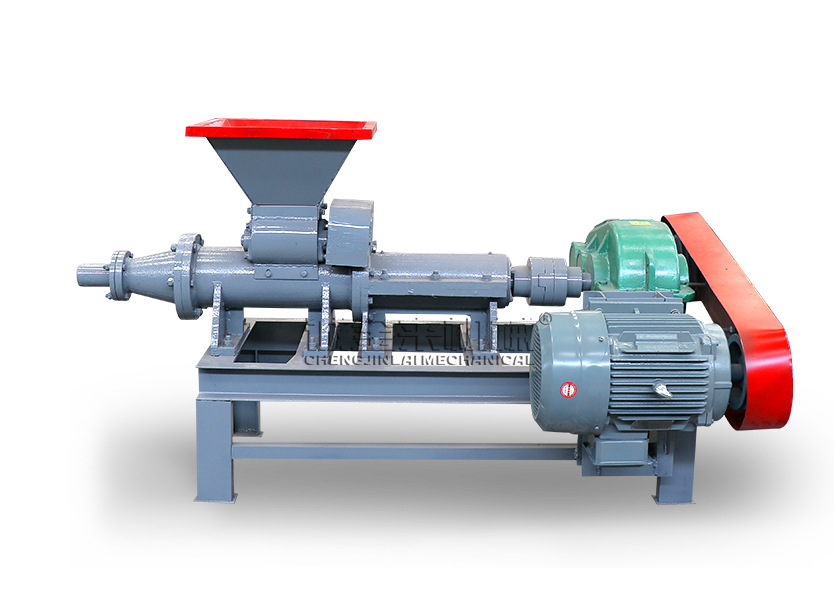

- Feeding: The coconut shells are automatically fed into the furnace via a conveyor belt, screw feeder or Z-Belt.

- Carbonization: After heating the main furnace, the temperature gradually rises. The initial temperature helps dry out some of the moisture in the coconut shell. When the temperature reaches 250 degrees Celsius, demethylation begins. Combustible gas starts to generate. At 280 degrees Celsius, the exothermic reaction begins. The hydrocarbon molecules split into smaller carbon molecules and hydrogen. charcoal begins to be produced. As the temperature hits 450 degrees Celsius, aromatic ring compounds begin reacting.

03 Discharging

- Coconut shell charcoal: Through a three-stage water-cooling discharger, coconut shell charcoal below 45 degrees Celsius is collected.

- Tar & wood vinegar collection (optional): Via the condenser, tar (biomass oil) and wood vinegar separate out and are collected separately.

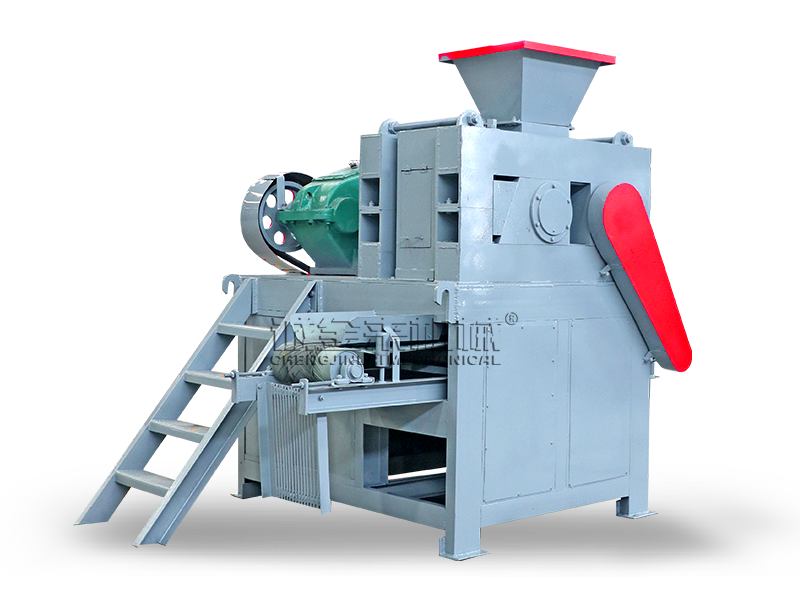

- Coconut shell charcoal briquette making (optional): After being processed by the coconut shell charcoal briquette machine, the original shape of charcoal can be made into the required shape, such as round, square, stick, etc.

04 Combustible Gas Recovery

- After condensation and sulfur removal treatment, combustible gas can be recovered and reused.

- We can also introduce the excess heat from the carbonization furnace into the dryer to recycle the combustible gas, thereby saving fuel for the dryer.

05 Exhaust Gas Treatment

- The emission gas is treated by a spray tower, water curtain de-dusting tower, and cooling tower. The processed emission gas meets the EU emission standards.

- Weiwa Group provides high-standard customized exhaust gas treatment system.

Features of Coconut Shell Charcoal Making Machine

Equipped with Alarm Device

The PLC electric cabinet has an alarm device, and there will be an alarm display and an alarm for some electrical failures.

With Explosion-proof Water Seal

There is an explosion-proof water seal at the combustible pipeline (to prevent abnormal pressure of combustible gas in the equipment)

Variable Frequency Fan Guide

The direction of the gas in all pipelines is led by the fan (the fan is variable frequency), and it will be displayed on the PLC when the pipeline is blocked.

High Heat Efficiency

The material is not in contact with the flue gas and is not polluted by hot air.

Good Energy-saving Effect

The heat utilization rate of this equipment is higher, the use of air heat ex-changer can effectively improve the thermal efficiency by 5-10%, and the energy saving effect is good.

How to profit from Coconut Shell Charcoal Making Machine

Coconut shell to charcoal is a circular economy solution. Coconut shells are converted into biomass charcoal resources. Biomass charcoal can be applied to both the coconut shell cultivation industry and the food processing industry. This allows for sustainable development and a truly closed-loop solution.

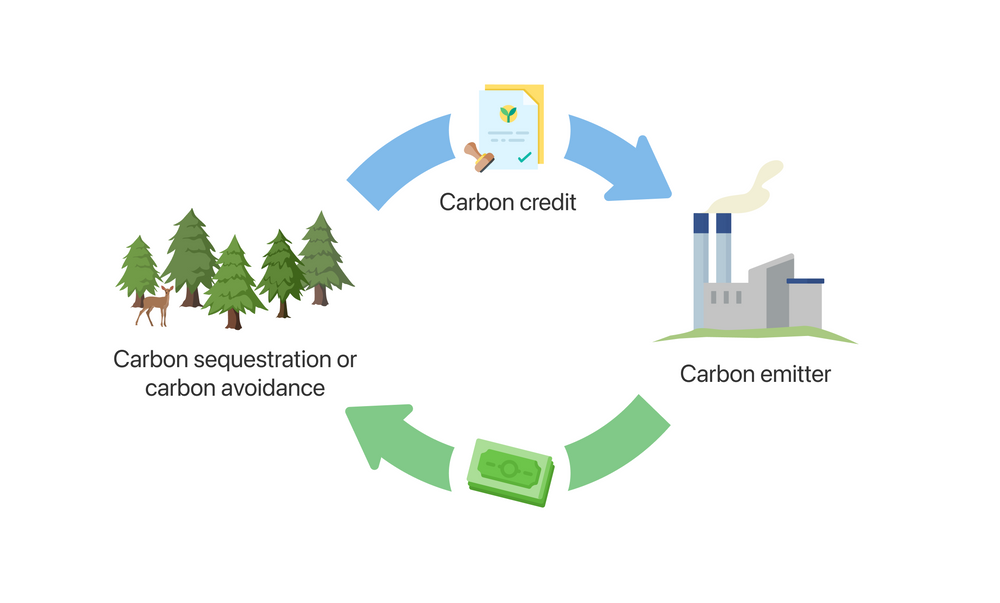

Guaranteed Access to Carbon Credit Trading

- Carbon Credit Trading: Quantified carbon reduction effect of biochar making machine generates carbon credits. Biochar producers can sell them on carbon market to companies with excess carbon emissions for carbon offset.

- Carbon Sequestration: Carbon content of biomass comes from atmospheric CO2 absorbed by photosynthesis. Biochar carbonization equipment stably stores this carbon in biochar. This avoids carbon emissions from natural degradation of biomass.

Soil Improvement

- 80% microporous structure to improve soil aeration and drainage

- Provide some trace elements, such as potassium, magnesium, zinc

- Alkalinity and ion exchange helps adjust soil pH and save on fertilizer costs

High-Quality Coconut Shell Biochar Output

By using Coconut Shell Charcoal Making Machine, we can get the most important end product, coconut shell charcoal. The charcoal can be further processed into hookah or barbecue charcoal, both of which have high values and can be applied in many areas. It is the most suitable machine for the hookah charcoal or BBQ charcoal production.

Barbecue Charcoal

- Low smoke

- Low ash content

- Long burning time

- Fruity wood aroma

- High carbon calories

Hookah Charcoal (Shisha Charcoal)

- High hardness

- Low smoke volume

- Long burning time

- Fruity wood aroma

- Stable temperature

Policy subsidy application

Some countries or regions provide subsidies or tax incentives for the use of biomass energy, such as the EU’s “Green New Deal” or China’s renewable energy support policy.

Coconut Shell Charcoal Composition Analysis

| No. | 1# |

| Kind | Coconut shell |

| Total Moisture Mt% | 9.1 |

| Analytical Water Mad% | 4.19 |

| Dry Basis Ash Ad% | 0.18 |

| Volatile Matter on Dry Basis Vd% | 6.95 |

| Fixed Carbon Fcad% | 88.68 |

| Sulfur Content on Dry Basis St.d% | 0.09 |

| Coking Characteristics 1-8CRC | |

| New national standard calorimeter dry basis high calorific value kcal/kg | 7277 |

| The new national standard calorimeter method receives the base low calorific value kcal/kg | 6724 |

**℃ Out of water and oil, the highest temperature **℃ The above data is for reference only.

Related Products

Wechat

Wechat

+8613838093177

+8613838093177