Bamboo charcoal making machine can produce charcoal from bamboo. Similar to wood charcoal and coconut shell charcoal, bamboo charcoal plays important roles in many aspects of human activities and has a high market value. Therefore, if there is plenty of bamboo in your place and you want to make money from them, you can choose bamboo charcoal machine. It will be an investment with a high ROI (rate of interest).

Prepare Suitable Bamboo Waste for Charcoal Making

Due to its unique characteristics and rapid growth, bamboo is an excellent raw material for charcoal production. The Weiwa bamboo biochar machine processes different kinds of waste bamboo, such as bamboo chips, poles, strips, fiber, sawdust, and pellets.

- Approximately 50% of bamboo biomass can be considered waste.

- Bamboo grows very fast, with certain species capable of reaching 91 cm (35 inches) within 24 hours.

- Converting bamboo waste into bioenergy can produce up to 10 MW of electricity from 10,000 tons of bamboo waste annually.

- Bamboo forests sequester around 30% more carbon dioxide than equivalent hardwood forests, meaning a more positive impact on climate change mitigation.

Note: If the bamboo moisture is below 15%, the carbonization effect of bamboo will be more in line with customer needs. In order to meet customers’ requirements, Weiwa Machinery Group provides dryers to remove the moisture of bamboo.

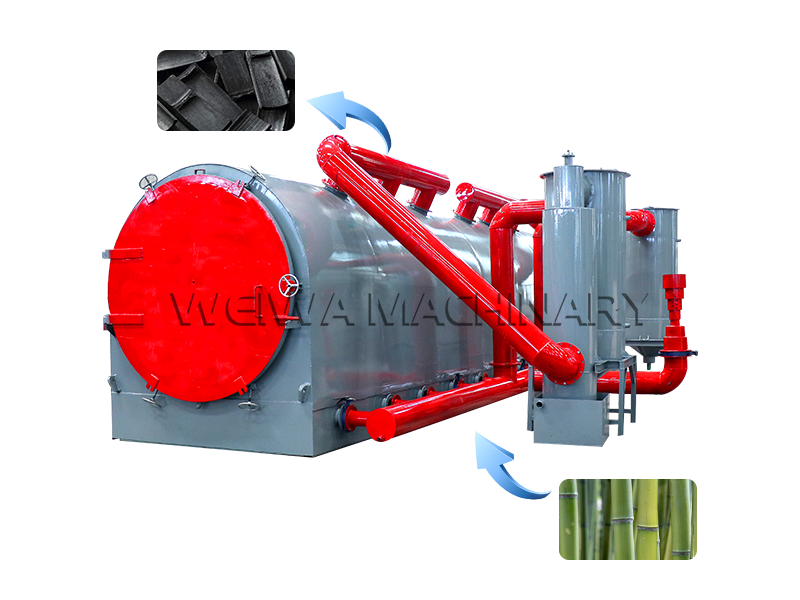

How to Use Bamboo Charcoal Making Machine

Bamboo Charcoal Making Machine consists of inner tank, insulation, furnace door, trolley, combustible gas reburning pipe, dehumidifying buffer tank, burner, exhaust pipe, and thermometer. The gasifier and flue gas purification device are the optional machine. This furnace using anaerobic dry distillation principle to remove volatile substances in biomass material, to carbonize the biomass material, carbonization process:

Feeding raw material and sealing the furnace → Preheating and drying the raw material → Anaerobic carbonization → Cooling and discharging the carbon, total four steps.

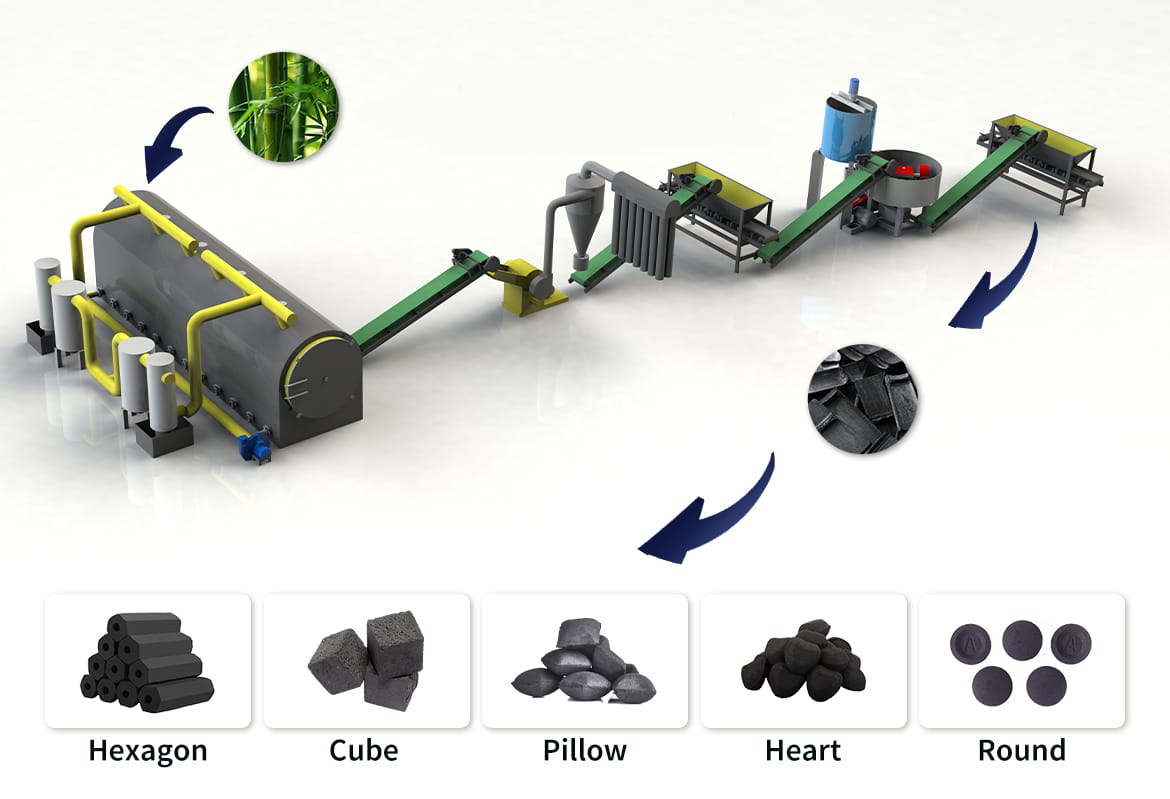

Optional Bamboo Charcoal Briquette Machine: Add Value with Ease

A bamboo charcoal briquette machine significantly enhances the value of bamboo charcoal by transforming loose bamboo biochar powder into compact, energy-dense briquettes (rod, spherical, cubic, and hexagonal shapes, etc.). Here’s how it boosts the utility and value of bamboo charcoal:

Higher Energy Density

Briquetting bamboo charcoal increases its energy density, making it an efficient and longer-burning fuel. This characteristic makes bamboo charcoal briquettes popular for cooking, heating, and industrial uses, providing a cost-effective alternative to conventional fuels like coal or wood.

Compact Form and Easy Storage

Bamboo charcoal briquettes are compact and uniform, allowing for easier storage, transportation, and handling compared to loose bamboo charcoal. This consistency appeals to customers, especially in bulk, because it reduces wastage and facilitates efficient storage.

Higher Market Value

Briquetting adds significant commercial value to bamboo charcoal by creating a refined product that’s ready for diverse uses. Compared to raw bamboo charcoal, briquettes fetch a higher price in the market, especially with increasing demand for eco-friendly alternatives.

How to Use Bamboo Charcoal Making Machine Bring Good Economic Profit

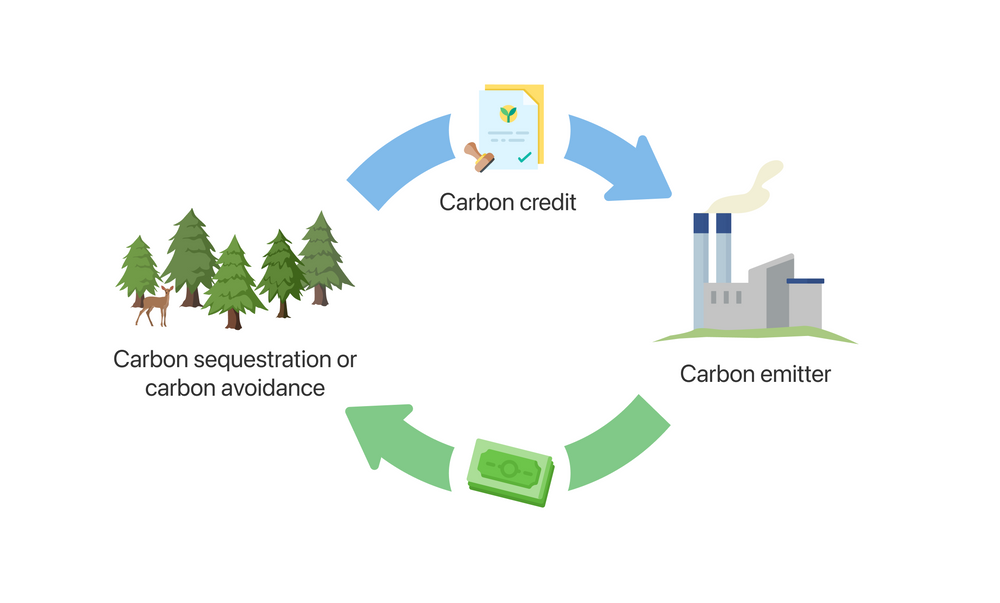

Carbon Sequestration

Bamboo biochar is rich in carbon and has a stable structure, allowing it to store carbon in the soil for many years. This long-term carbon sequestration helps reduce the harmful effects of carbon dioxide on the environment.

Heating Fuel & BBQ & Hookah

Bamboo charcoal has a fixed carbon content of over 80%, making its calorific value about 30% higher than wood charcoal. Therefore, it suits to be:

- used for BBQ or Hookah.

- used as fuel in cement plants, power factory, brick plants, etc.

Soil Improvement

Bamboo biochar is a good material to improve soil quality. It can:

- regulate soil pH, etc.

- improve soil aeration and drainage and enhance soil structure;

- increase nutrient retention and promote plants’ healthier growth and higher yields.

Test Report of Resulting Bamboo Biochar

Laboratory Report on Bamboo Biochar

You can see the carbonized bamboo biochar has high fixed carbon content, low sulfur content, and relatively low ash and volatile matter content. This implies high quality.

| Assay NO | #1 |

| Kind | Bamboo |

| Whole water Mt% | 6.98 |

| Analytical water Mad% | 1.74 |

| Dry basis ash Ad% | 16.62 |

| Volatile matter on a dry basis Vd% | 18.2 |

| Dry basis fixed carbon Fcad% | 63.44 |

| Sulfur content on a dry basis St.d% | 0.02 |

| Coking characteristics 1-8CRC | 1 |

| New national standard calorimeter dry basis high calorific value kcal/kg | 5679 |

| The new national standard calorimeter method receives the base low calorific value kcal/kg | 5171 |

| Remarks:**degrees Celsius Out of water and oil, the highest temperature **degrees Celsius The above data is for reference only. | / |

Applications of the horizontal Bamboo Charcoal Making Machine

Other types of carbonization furnaces, such as continuous carbonization furnaces and lifting carbonization furnace are important equipment for the production of charcoal.

Therefore, charcoal producers and charcoal processing plants should choose their own carbonization machines according to their actual production needs.

Continuous Carbonization Furnaces

Lifting Carbonization Furnace

Why do so many manufacturers choose Weiwa horizontal Bamboo Charcoal Making Machine?

By summarizing the past data of seling, we can find that this horizontal carbonization furnace is popular with charcoal suppliers.Why? Because it has many advantages which can attract biochar manufacturers to invest in as follows:

Stocks

We have a lot of stocks,we can delivery quickly.

Cerificate

We have obtained many cerification,so you don’t need worry about the quality of our machine.

Factory

We are factory,we can provide the same quality machine with a lower price.

Henan Weiwa Machinery Manufacturing Co., Ltd. is a professional manufacturer of charcoal manufacturing machinery in China. Continuous improvement and innovation is our production philosophy. Our tenet: Survive by quality, develop by credit, quality first, credit first, integrity-based, customer first.

Wechat

Wechat