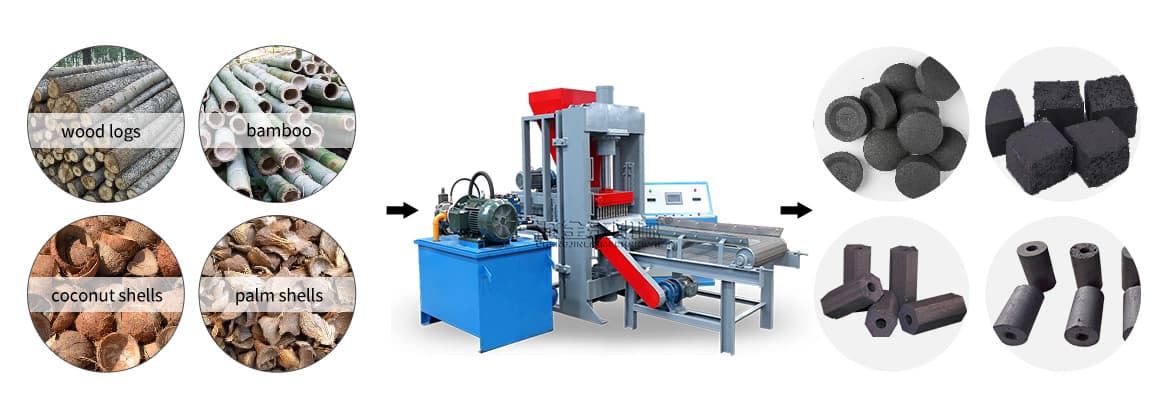

Shisha charcoal briquette production line raw materials and final products

Shisha charcoal briquette production line has a wide range of raw materials,such as wood logs, bamboo, coconut shells, palm shells, wood chips, rice husks, nut shells, walnut shells and various biomass raw materials.

Charcoal Advantages

The process is characterized by high production capacity, high automation degree, high product quality, energy conservation, environment protection, low emission of harmful substances and high utilization rate of industrial metal/mining powder.

And the Advantages of charcoal is Long burning time, high calorific value, no smoke, no explosion, environmental protection and economy.

Charcoal Applicable Fields

Charcoal can be used for domestic combustion, boilers, barbecues, fireplace heating, power plants and other aspects.

In addition, due to its unique microporous structure and super adsorption capacity, it is widely used in many fields such as food, pharmacy, chemical industry, metallurgy, national defense, agriculture and environmental protection.

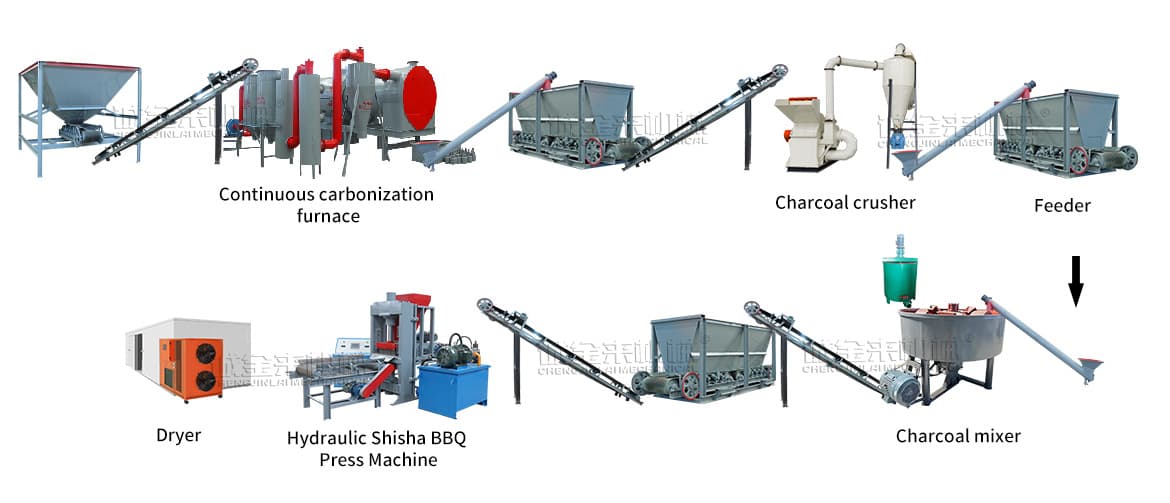

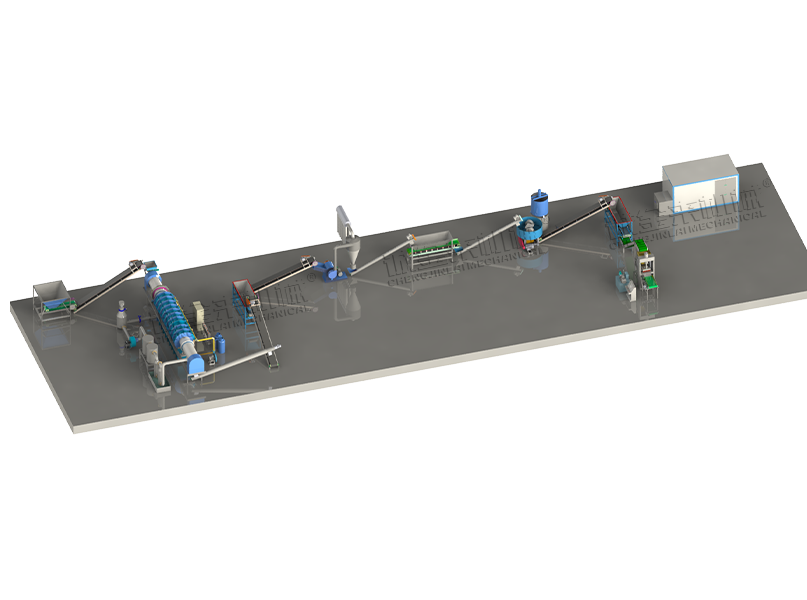

Shisha charcoal briquette production line process flow

Now you can see this roughly production line, exact production line is according to your requirement.

Raw materials—- Carbonization furnace —- Charcoal crusher—- Binder mixer—- Wheel mill—- Shisha charcoal machine—- finished shisha charcoal briquettes—- Dryer

A.Double mouth crusher is the main equipments in the crushing raw mateials in the shisha charcoal briquette production process.It is a fine crushing equipment.

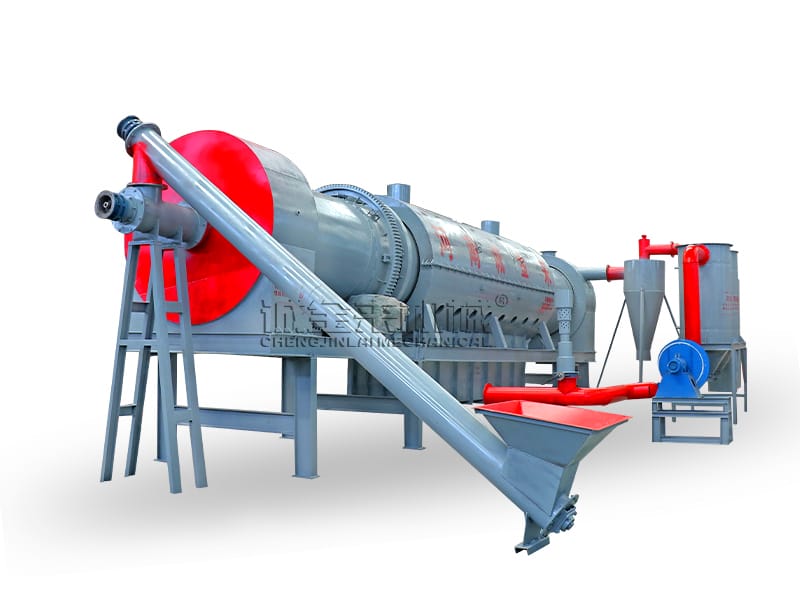

B.Rotary drum dryer is the main equipments in the drying raw mateials in the shisha charcoal briquette production process, which is reliable in operation, flexible in operation, strong in adaptability, and large in processing capacity. The diameter and length of the equipment are determined according to the drying requirements.

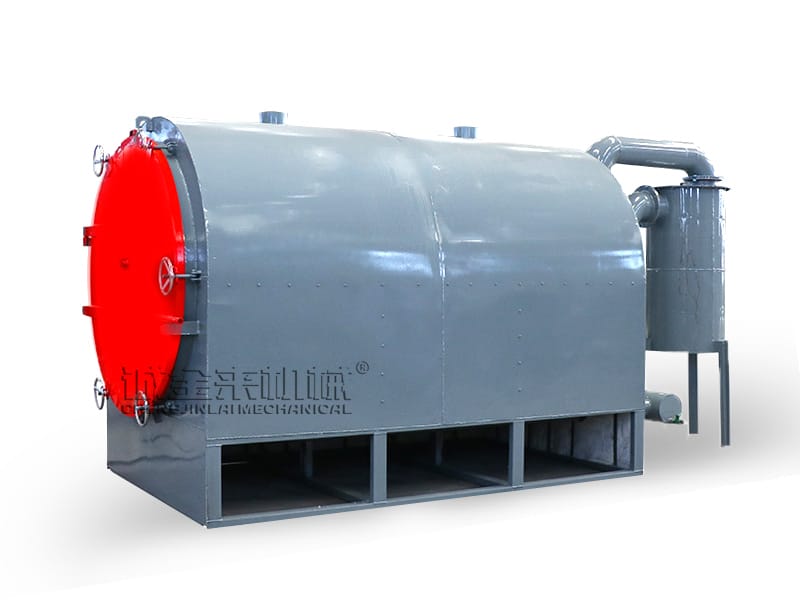

C.Continuous carbonization furnace is widely used in various fields of charcoal processing and production.It is one of the important equipment for shisha charcoal briquette production line.

D.Hammer mill is is the main equipments in the re-crushing raw mateials in the shisha charcoal briquette production process that can process all kinds of wood, wood scraps, branches, branches, wood chips, board trim, bark, bamboo, bamboo bark and other raw materials into sawdust at one time.

E.Wheel mill mixer is a model that combines wheel milling and mixing designed according to the advantages of the latest foreign wheel milling and mixing equipment. Suitable for mixing powder and granular materials, such as carbon powder, coal powder, clay, refractory mud, tailing sand, slag, molding sand, etc.

F.Adhesive mixing barrel is driven by the motor triangle belt to drive the impeller to rotate, and the water and the binder are fully mixed uniformly. It is a necessary device to increase the reaction time of the agent and strengthen the reaction quality of the material.

G.Shisha charcoal briquette machine is an important molding equipment in the shisha charcoal briquette production process. This equipment can press blue charcoal, coke dust, charcoal powder, ash powder, fertilizer and other powders.

Our Engineer Team Can Provide Free Production Line Design

When you plan to configure a carbonization production line, please let us know your details.

These materials include:

1.Raw material type, size, moisture

2.Plant size

3.Transformer capacity

4.Type and size of finished product

5.Demand for output

As detailed as possible, the best, in order to customize your own carbonization production line equipment, and we will provide you with 3D site planning diagrams for free.

*Different materials will be designed into different production solution, customer at the time of consultation need inform us of the materials’ moisture, particle size, yield, briquettes size, shape, some special circumstances maybe need auxiliary equipment such as other types of crusher,other types of mixer,screen mesh, vibration sieve, binder feeder, liquid mixing tank, magnetic separator, electronic belt weigher, variable-frequency drive.

Related Posts

Wechat

Wechat

+8613838093177

+8613838093177