Industrial wood chip charcoal block production line is an advanced equipment that efficiently utilizes biomass waste such as wood chips,rice husk,peanut shells,sawdust ect material. and is designed to convert wood chips into high calorific value charcoal blocks to meet the market demand for environmentally friendly fuels. As the concept of sustainable development becomes more and more popular, wood chip charcoal blocks are gradually gaining widespread attention due to their low pollution and high efficiency.

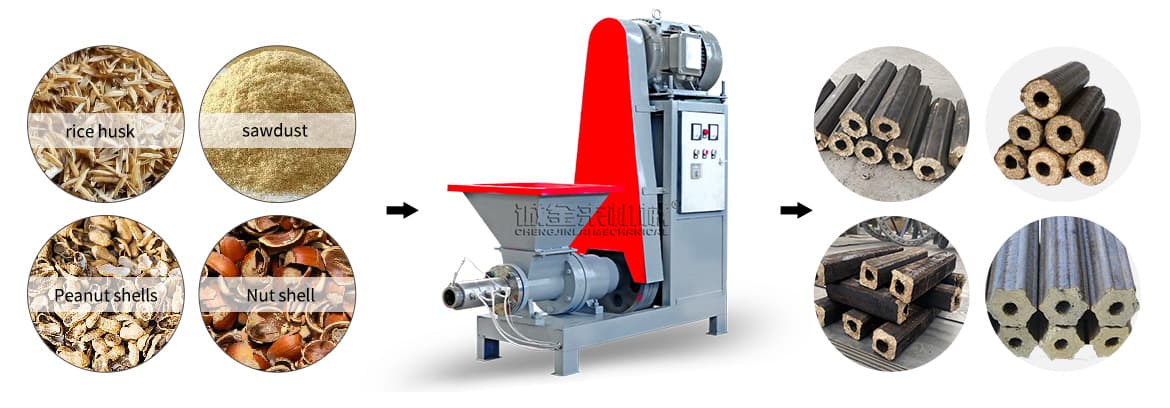

Charcoal Briquettes Making Machine Raw Materials & Final Products

Charcoal briquette making machine has a wide range of raw materials,such as wood logs, bamboo, coconut shells, palm shells, wood chips, rice husks, nut shells, walnut shells and various biomass raw materials.

Raw material is graphite powder, coal powder or mineral powder, it can be crushed directly and added into the appropriate binderand stirred evenly before moulding and making rods.

(Size:less than 5 mm;Moisture content:less than 25%)

Final products:

◆This bio-fuel briquette is 45-80mm in diameter, occurs in the hollow quadrangular or hexagonal cylinder or hollow hexagonal with a 15-20mm hole through the body.

◆The available shape: square, hexagonal, pentagon, pentagon with edge, hexagon with edge.

◆The available diameter could be: 50mm,60mm,70mm,80mm and so on

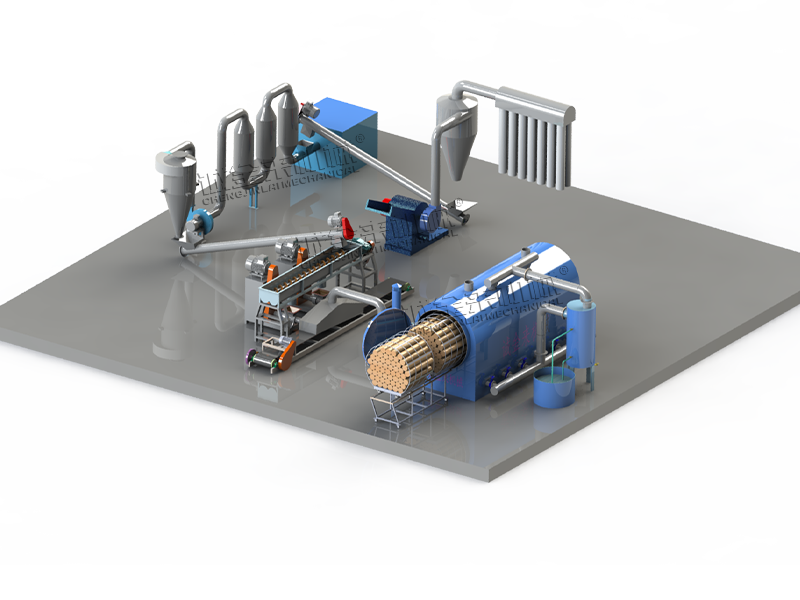

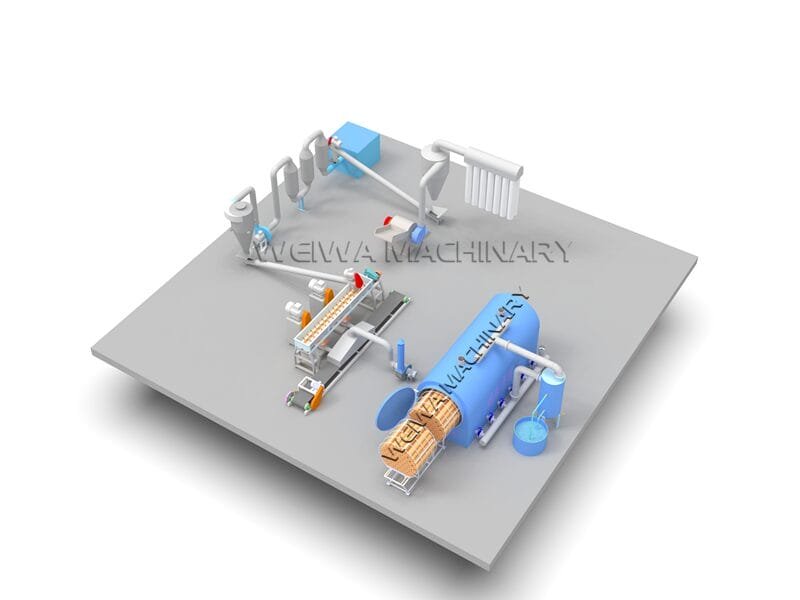

Wood Charcoal Briquette Production Line Process Flow

Step 1. Grinder to crush the raw material into small pieces (diameter is about 3-5mm)

Step 2. Dryer to dry the raw material till the moisture is less than 12%

Step 3. Put the material into wood briquette machine without add any chemical goods,

Step 4. Carbonization the wood briquette stick

Step 5. Finished charcoal can be 45mm , 50mm,60mm ,70mm ,80mm diame

A.Drum chipper is a special equipment for producing all kinds of high-quality wood chips. It can cut logs and small-diameter wood into high-quality wood chips with uniform size and flat cuts.

B.Double mouth crusher is a fine crushing equipment that can process all kinds of wood, wood scraps, branches, branches, wood chips, board trim, bark, bamboo, bamboo bark and other raw materials into sawdust at one time.

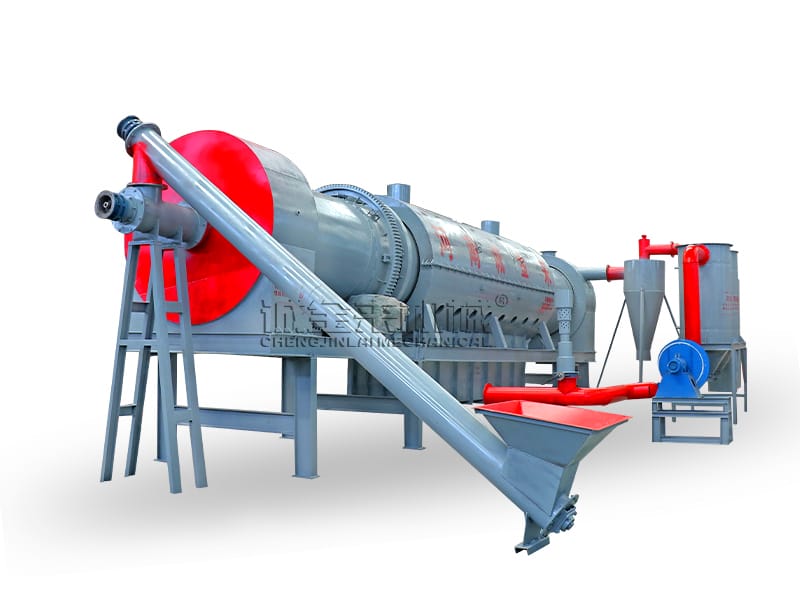

C.Rotary drum dryer is one of the traditional drying equipment, which is reliable in operation, flexible in operation, strong in adaptability, and large in processing capacity. The diameter and length of the equipment are determined according to the drying requirements.

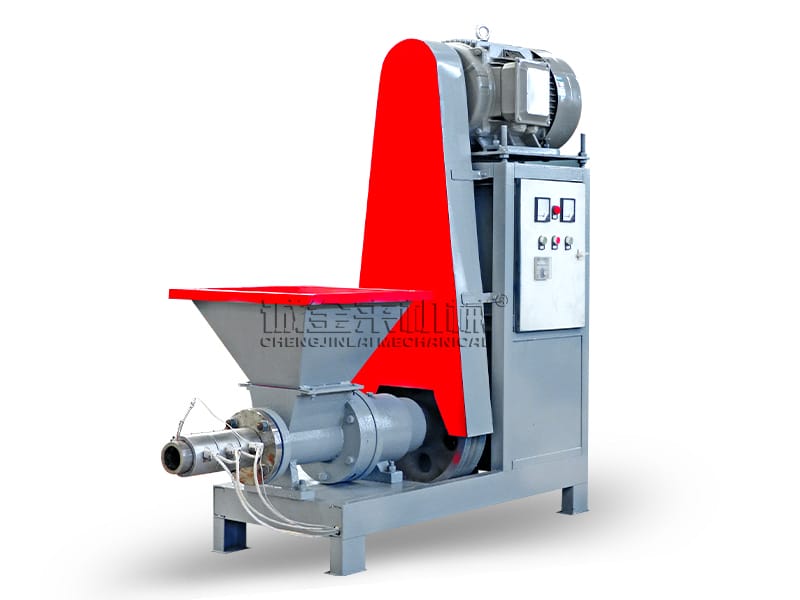

D.Wood charcoal briquette machine is a kind of forming equipment, which mainly passes qualified sawdust and wood materials or biomass materials (under 5mm in size, 12% moisture) through spirals, high pressure forming cylinders and heating rings. The machine-made rod is formed under high temperature and high pressure.

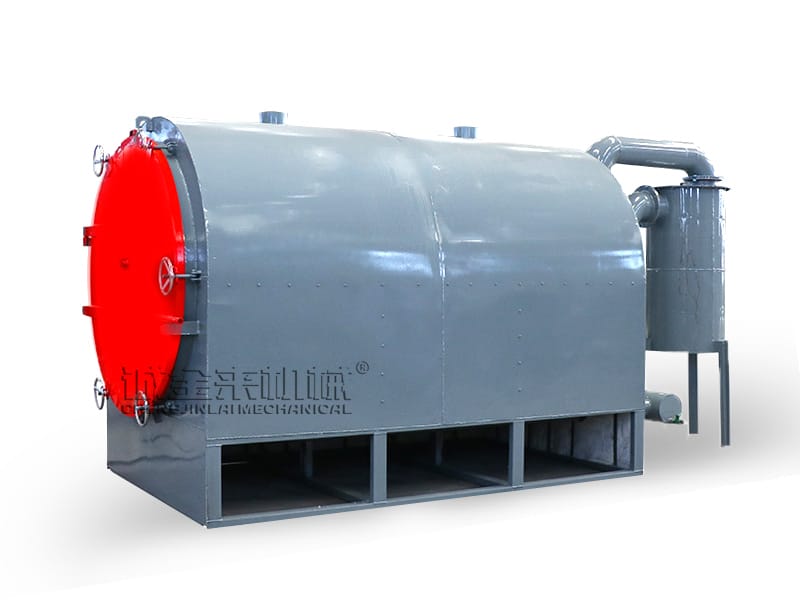

E.Hoisting carbonization furnace is an environmentally friendly and smokeless carbonization equipment. It can not only carbonize machine-made rods, but also directly carbonize raw materials such as logs, wood blocks, coconut shells, and tree bark.

We Provide 100% Free Charcoal Machine Production Line Design

When you plan to configure a carbonization production line, please let us know your details.

These materials include:

1.Raw material type, size, moisture

2.Plant size

3.Transformer capacity

4.Type and size of finished product

5.Demand for output

As detailed as possible, the best, in order to customize your own carbonization production line equipment, and we will provide you with 3D site planning diagrams for free.

*Different materials will be designed into different production solution, customer at the time of consultation need inform us of the materials’ moisture, particle size, yield, briquettes size, shape, some special circumstances maybe need auxiliary equipment such as other types of crusher,other types of mixer,screen mesh, vibration sieve, binder feeder, liquid mixing tank, magnetic separator, electronic belt weigher, variable-frequency drive.

In summary, the industrial wood chip charcoal block production line is an important environmental protection technology. It effectively converts wood chip resources into high-value fuel and helps achieve the goal of sustainable development. If you are interested in the equipment or have any questions, please leave a message and we will wholeheartedly provide you with professional answers and solutions!

Related Posts

Wechat

Wechat