Introduction: The Rising Demand for Charcoal Briquettes

In recent years, the global demand for charcoal briquettes has surged, driven by their applications in BBQs, industrial heating, and eco-friendly fuel alternatives. As a leading manufacturer, Weiwa Machinery specializes in ball charcoal briquette machines, production lines, and complete plants that transform raw materials into high-density briquettes efficiently.

Understanding Charcoal Briquette Machines: Types & Functions

What is a Ball Charcoal Briquette Machine?

A ball charcoal briquette machine is a specialized press that compresses charcoal dust, biomass, or coal fines into uniform ball-shaped briquettes. These machines are crucial for producing high-quality, long-burning briquettes with minimal binder requirements.

Weiwa Machinery offers customizable ball briquette machines that adjust to different raw materials and production scales, ensuring high density and durability.

Types of Charcoal Briquette Machines

While ball briquette machines are popular for their uniform shape, other variants include:

Each type serves different markets, but ball briquettes remain a top choice due to their clean burn and easy handling.

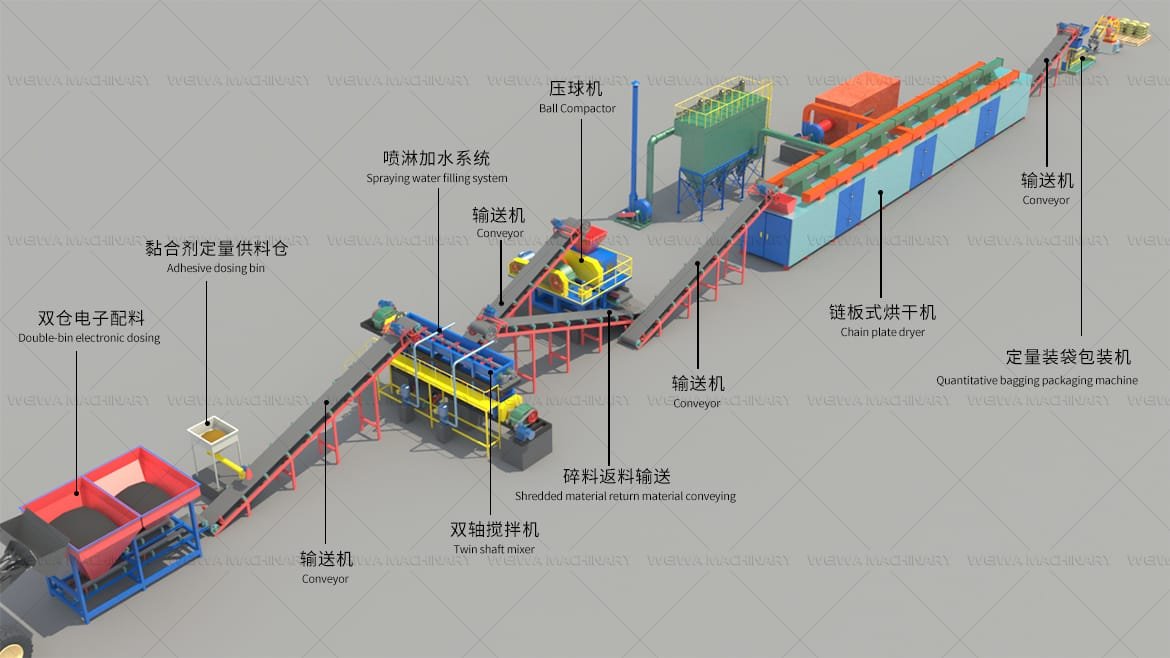

How a Ball Charcoal Briquette Production Line Works

Step-by-Step Production Process

https://youtu.be/qkZE9rijtKA

A complete charcoal briquette machine product line includes:

- Raw Material Preparation – Crushing and drying charcoal dust or biomass to the right moisture level (~8-12%).

- Briquetting – Feeding the material into the ball charcoal briquette machine, which compresses it into dense balls.

- Drying – Using a rotary dryer or natural sun drying to harden the briquettes for storage.

- Packaging & Distribution – Ready for sale in BBQ markets, industrial clients, or export.

Weiwa’s production line is designed for efficiency, reducing waste and maximizing output.

Market Potential: Why Invest in a Charcoal Briquette Business?

Growing Global Demand

- BBQ & Outdoor Cooking: Consumers prefer cleaner, smokeless briquettes over traditional lump charcoal.

- Industrial Fuel: Foundries, ceramics, and food processing industries use briquettes as a cost-effective alternative to coal.

- Eco-Friendly Trends: Governments promote biomass briquettes to reduce deforestation and carbon emissions.

Profitability Insights

- Low raw material cost (charcoal dust, sawdust, agricultural waste)

- High demand in domestic & international markets

- Scalable production (small workshops to large plants)

Weiwa Machinery helps clients design customized production lines based on their budget and target market.

Why Choose Weiwa Machinery for Your Briquette Line?

30+ Years of Expertise

With over three decades in the industry, Weiwa has refined its ball charcoal briquette machines for durability, efficiency, and high output.

Customized Solutions & Professional Support

- Design drawings & site planning tailored to your facility

- Professional after-sales team for installation and troubleshooting

- OEM/ODM services for unique client requirements

Competitive Advantage

- Energy-efficient machines reducing operational costs

- High briquette density & low breakage rate

- Global export experience (Africa, Southeast Asia, Europe, etc.)

Start Your Charcoal Briquette Business with Weiwa

The ball charcoal briquette machine market is booming, and with the right equipment, your business can thrive. Whether you need a small-scale production line or a full-scale plant, Weiwa Machinery provides reliable, high-performance machinery backed by expert support.

Contact us today for a free consultation, custom quotes, and factory layout planning!

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177