Why Charcoal Ball Press Machines Are Booming in Southeast Asia?

In recent years, the demand for charcoal briquettes—especially in ball form—has surged across Southeast Asia, with the Philippines emerging as a key market. Driven by the need for cleaner-burning fuel alternatives (compared to raw wood charcoal) and the rise of grilling, hospitality, and industrial applications, businesses are turning to efficient production solutions like Weiwa Machinery’s Ball Charcoal Briquettes Machine.

As a leading manufacturer with 30+ years of experience, Weiwa recently deployed an engineer to the Philippines to oversee the installation and commissioning of a complete charcoal ball press machine line for a local client.

Understanding the Charcoal Ball Press Machine & Production Line

What Is a Ball Charcoal Briquettes Machine?

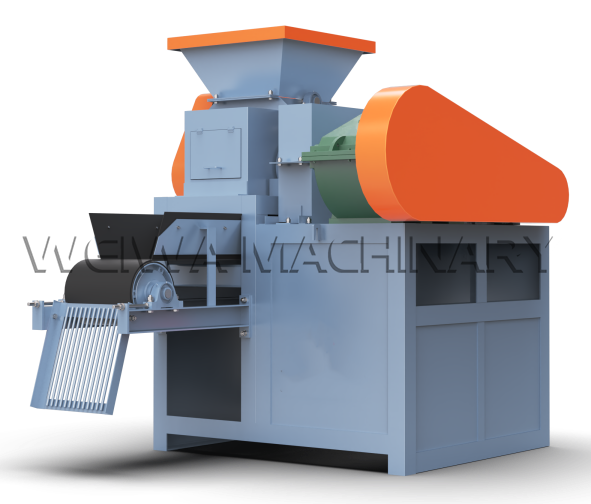

A Ball Charcoal Briquettes Machine (also called a charcoal ball press machine) is a specialized piece of equipment designed to compress charcoal dust, fines, or scrap into uniform, dense balls. Unlike traditional lump charcoal, these balls offer:

- Higher combustion efficiency (longer burn time).

- Reduced smoke emissions (better for indoor/outdoor use).

- Easier handling & packaging (ideal for commercial sale).

Our Charcoal Briquette Machine line includes mechanical and hydraulic models, catering to different production scales—from small workshops to large factories.

How Are Charcoal Balls Made?

The production process involves:

- Raw Material Preparation – Charcoal dust is collected (often from sawdust, coconut shells, or wood waste).

- Binding Agent Mixing – A small amount of starch, molasses, or clay is added to help the particles bind.

- Feeding into the Press Machine – The mixture is fed into our charcoal ball press machine, which applies high pressure to form perfectly round balls.

- Drying – The freshly pressed balls are dried (naturally or in a dryer) to achieve hardness.

Why the Philippines Is a Hot Market for Charcoal Balls?

Growing Demand for Clean Cooking & Grilling

The Philippines, with its tropical climate and outdoor lifestyle, has a strong market for grilling and barbecue fuels. Additionally, urban households seek affordable, smoke-free alternatives to traditional firewood.

Our client in the Philippines recognized this trend and partnered with Weiwa to establish a local production line, reducing reliance on imported charcoal products.

Government & Environmental Regulations

The Philippine government has been promoting sustainable fuel alternatives to combat deforestation. Charcoal briquettes (especially those made from agricultural waste) align with these policies, creating incentives for local producers.

Weiwa’s On-Site Engineer Support in the Philippines

Challenges in Overseas Machine Installation

When exporting charcoal ball press machines internationally, challenges include:

- Technical setup (ensuring proper voltage, foundation, and operation).

- Training local staff on machine maintenance.

- Debugging unforeseen issues during the first runs.

To address these, Weiwa dispatched an experienced engineer to the Philippine client’s facility for:

✅ Machine installation & calibration

✅ Hands-on operator training

✅ Troubleshooting & efficiency optimization

https://youtube.com/shorts/e5a73m_aSqs?feature=share

Within two weeks, the client’s charcoal ball production line was fully operational, producing 1-30 ton of charcoal balls per hour (depending on model). The client reported:

- Faster production than manual methods.

- Consistent ball shape & quality.

- High customer demand in local markets.

Southeast Asia’s Potential for Charcoal Briquette Machines

Beyond the Philippines, countries like Indonesia, Vietnam, Thailand, and Malaysia show strong potential due to:

- Abundant biomass waste (coconut shells, rice husks, etc.).

- Growing eco-friendly fuel trends.

- Export opportunities to Japan, Korea, and the Middle East.

Weiwa is actively expanding its presence in these markets, offering:

- Localized machine designs.

- Multilingual technical support.

- Flexible financing & bulk order discounts.

Why Choose Weiwa Machinery?

With over 30 years of expertise, Weiwa is a trusted name in charcoal briquette machinery. Our advantages include:

Customized Solutions

We design tailored production lines based on your raw materials, output goals, and space constraints.

Professional After-Sales Team

Our engineers provide on-site installation, training, and long-term support—just like in the Philippines project.

Factory-Direct Pricing & Fast Delivery

As a manufacturer (not a middleman), we offer competitive prices and efficient lead times.

Free Consultation & Design Planning

Need help planning your charcoal ball press machine layout? Contact us for a free blueprint and quote.

The Future of Charcoal Ball Production in Southeast Asia

The Philippines’ success story proves that Weiwa’s Ball Charcoal Briquettes Machine can transform raw waste into profitable, eco-friendly fuel. With rising demand, supportive policies, and Weiwa’s expert support, Southeast Asia is poised for explosive growth in charcoal ball production.

Ready to start your own line? Contact Weiwa Machinery today for a free consultation, custom design, and global shipping.

About Weiwa Machinery

Weiwa Machinery is a leading manufacturer of charcoal briquette machines with over 30 years of industry experience. Specializing in Ball Charcoal Briquettes Machines, Charcoal Briquette Machines, and complete production lines, we serve clients in over 50 countries, including the Philippines, Indonesia, Vietnam, and beyond.

Our strengths include:

✔ 30+ years of engineering expertise

✔ Professional after-sales team (on-site installation, training, troubleshooting)

✔ Customized solutions (design drawings, site planning, bulk orders)

✔ Factory-direct pricing & fast global delivery

Contact us today for a free quote, machine catalog, or consultation. Let Weiwa help you turn waste into profit with our high-efficiency charcoal ball press machines.

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177