On a bright morning at our production facility, the hum of machinery and the excitement of our team marked a milestone moment — the successful packaging and shipment of one of our advanced biomass briquette machines to Bhutan. This shipment is not just about exporting equipment; it’s about empowering a nation to harness its biomass resources sustainably and transform waste into valuable energy.

Why Bhutan Need Biomass Charcoal Briquette Machine?

Nestled in the Eastern Himalayas, Bhutan is renowned for its commitment to environmental conservation and Gross National Happiness. Despite its small size, the country has been actively seeking renewable energy solutions to reduce reliance on firewood and fossil fuels, especially in rural areas. Biomass, particularly from agricultural residues and forestry by-products like sawdust, offers an abundant and underutilized resource.

The introduction of a biomass briquette machine into Bhutan’s energy landscape is more than a technological upgrade — it’s a sustainable revolution. By converting loose biomass materials into compact, high-energy briquettes, Bhutan can address fuel shortages, reduce deforestation, and lower carbon emissions.

What’s Inside the Biomass Briquette Production Line?

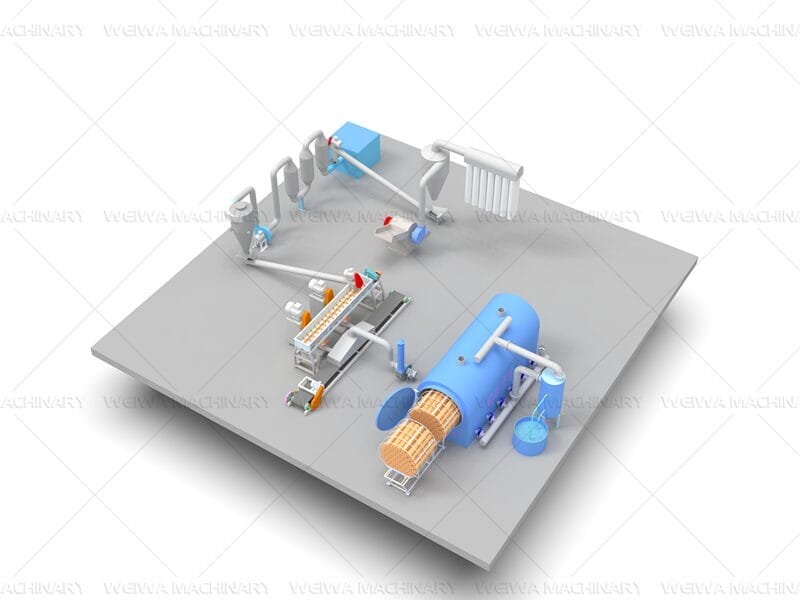

Our recent shipment to Bhutan includes a sawdust briquetting machine, a crusher, and auxiliary components that form a complete briquette production line. Let’s delve into how each component contributes to the efficient transformation of raw biomass into usable fuel.

The Role of the Biomass Briquette Machine

At the heart of the production line is our biomass briquette machine, designed to compress biomass materials such as sawdust, rice husk, and agricultural waste into dense briquettes without the need for binders. This machine utilizes high pressure and temperature to form solid fuel blocks that are easy to store, transport, and burn efficiently.

For Bhutan, where sawdust is abundantly available from local timber industries, this machine offers a practical solution to convert waste into a valuable commodity. The briquettes produced can be used in households, institutions, and even industrial boilers as a cleaner alternative to firewood or coal.

How Biomass Briquetting Machine Works?

Biomass briquetting is a process that transforms loose, low-density biomass into compact, high-density fuel briquettes. This is achieved through mechanical compression, which removes air pockets and increases the material’s energy content per unit volume.

Step-by-Step Process

- Material Preparation: Biomass materials such as sawdust, agricultural residues, or wood chips are collected and, if necessary, dried to achieve the optimal moisture content (typically 8-12%).

- Feeding: The prepared biomass is fed into the biomass briquette machine or sawdust briquetting machine, where it is compressed under high pressure.

- Compression and Heating: As the biomass moves through the machine, it is subjected to intense pressure and moderate heat. This causes the lignin in the biomass (a natural binder) to soften and bind the particles together.

- Briquette Formation: The compressed biomass is extruded through a die to form cylindrical or hexagonal briquettes. These briquettes are then cooled and solidified for storage and transportation.

- Quality Control: The final briquettes are inspected for size, density, and durability to ensure they meet the required standards for burning efficiency and safety.

This process not only enhances the fuel value of biomass but also reduces its volume, making it easier to handle and store.

Why Biomass Briquettes Matter for Bhutan?

Bhutan’s energy sector is predominantly reliant on hydropower, but rural and off-grid areas still depend on traditional biomass like firewood for cooking and heating. The introduction of biomass briquettes offers several benefits:

- Environmental Conservation: By utilizing agricultural and forestry waste, Bhutan can reduce deforestation and carbon emissions.

- Energy Security: Briquettes provide a reliable and sustainable energy source, especially in regions with limited access to electricity or fossil fuels.

- Economic Opportunities: The production and sale of biomass briquettes can create jobs and generate income for local communities.

- Waste Management: Converting waste materials into valuable fuel helps address the problem of biomass disposal and promotes a circular economy.

Customized Solutions for Bhutan’s Unique Needs

At Weiwa Machinery, we understand that every region has unique requirements. That’s why we worked closely with our Bhutanese partners to customize the biomass briquette machine and sawdust extruder to suit local conditions. From adjusting the machine’s capacity to ensuring compatibility with the types of biomass available in Bhutan, we prioritized flexibility and efficiency.

Our team also provided training and technical support to ensure a smooth transition and optimal operation of the equipment. This collaborative approach underscores our commitment to delivering not just machines, but sustainable solutions.

Behind the Scenes of the Shipment to Bhutan

The process of shipping a biomass briquette production line to Bhutan involves meticulous planning and coordination. From quality checks and packaging to logistics and customs clearance, every step was executed with precision to ensure the equipment reached its destination safely and on time.

Our team at Weiwa Machinery oversaw the entire process, ensuring that the biomass briquette machine, sawdust briquetting machine, and biomass extruder were carefully packed to withstand the rigors of transportation. We also provided detailed documentation and installation guidelines to facilitate a seamless setup process in Bhutan.

Empowering Bhutan with Sustainable Technology

The shipment of our biomass briquette production line to Bhutan is a testament to Weiwa Machinery’s dedication to promoting sustainable energy solutions worldwide. By providing Bhutan with the tools to convert its biomass resources into clean, efficient fuel, we are helping the country take a significant step towards energy independence and environmental sustainability.

This project also highlights the importance of international collaboration in addressing global challenges like climate change and energy poverty. Through our partnerships with clients in Bhutan and beyond, we aim to create a ripple effect of positive change, one briquette at a time.

A Brighter, Greener Future for Bhutan

As the biomass briquette machine and its accompanying equipment make their way to Bhutan, we are filled with anticipation for the positive impact they will have. From reducing reliance on firewood to promoting sustainable waste management, the benefits of this technology are far-reaching.

At Weiwa Machinery, we are proud to play a role in Bhutan’s journey towards a greener future. Our biomass briquette machine, sawdust briquetting machine, and biomass extruder are more than just equipment — they are enablers of change, empowering communities to harness their resources wisely and sustainably.

We look forward to continuing our work with partners around the world, delivering innovative solutions that drive progress and protect the planet.

About Weiwa Machinery

Weiwa Machinery is a leading manufacturer of biomass processing equipment, specializing in biomass briquette machines, charcoal extrude machine,ball charcoal press machine,carbonization furnace, and complete briquette production lines. With years of experience and a commitment to innovation, we provide customized, reliable, and efficient solutions to clients across the globe. Our mission is to empower businesses and communities to turn biomass waste into valuable energy, contributing to a more sustainable and eco-friendly future.

Whether you’re looking to start a biomass briquette business or upgrade your existing production line, Weiwa Machinery is your trusted partner in sustainable energy solutions. Contact us today to learn more about our products and how we can support your goals.

Wechat

Wechat

+8613838093177

+8613838093177