The Rising Demand for Charcoal Briquettes in South Africa

South Africa, like many other countries, is experiencing a growing demand for sustainable fuel alternatives, and charcoal briquettes have emerged as a cost-effective, eco-friendly solution. With the increasing need for efficient charcoal production, the ball briquette machine has become a game-changer for manufacturers.

At Weiwa Machinery, we specialize in providing high-quality charcoal making machines, including ball briquette machines and complete production lines, tailored to the South African market. Our equipment ensures high efficiency, durability, and profitability for our clients.

What is a Ball Briquette Machine?

A ball briquette machine is a mechanical press that compresses loose biomass materials (such as charcoal dust, coal fines, or agricultural waste) into uniform, dense balls or briquettes. These briquettes are easier to store, transport, and burn efficiently compared to loose charcoal.

How Does a Ball Briquette Machine Work?

The machine uses mechanical pressure (with or without binders) to form round or cylindrical briquettes. The key components include:

- Feeding system (ensures consistent material flow)

- Compression chamber (where pressure is applied)

- Mold/die (determines the shape and size of the briquettes)

- Discharge system (collects the finished briquettes)

In South Africa, where charcoal production is booming, these machines help reduce waste, improve fuel efficiency, and increase profitability for manufacturers.

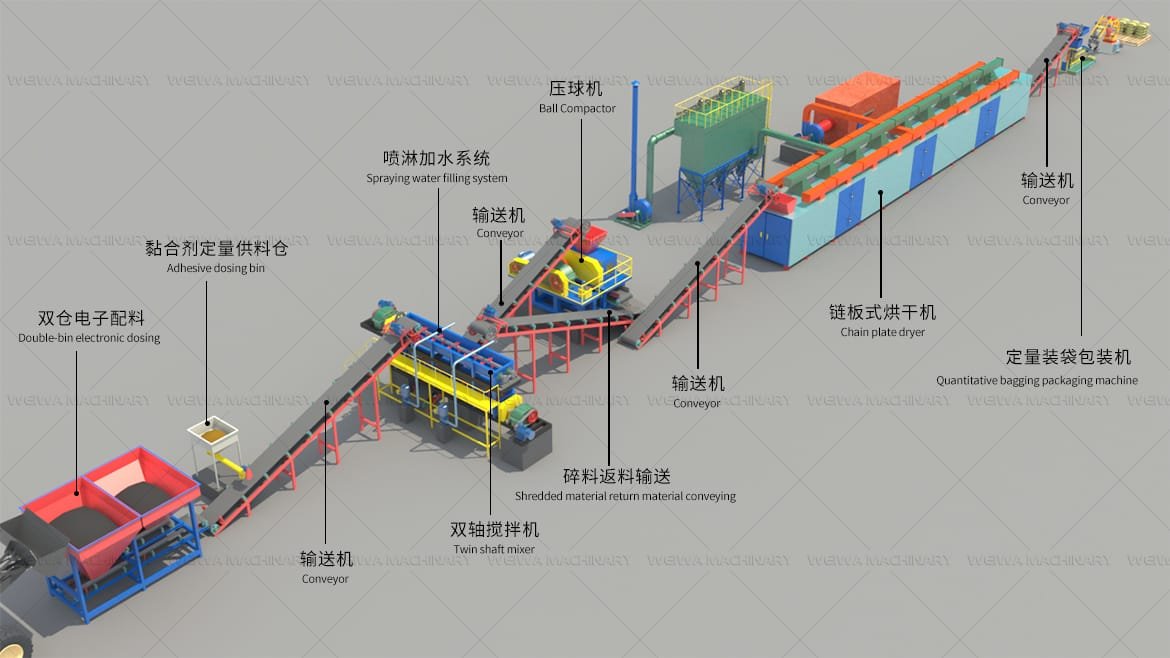

The Charcoal Ball Briquette Production Line

A complete charcoal ball briquette production line includes:

- Raw Material Crushing (if needed)

- Drying (to reduce moisture content)

- Mixing (optional, if binders are used)

- Briquetting (using the ball briquette machine)

- Drying (final curing of briquettes)

Why South African Clients Prefer Weiwa’s Production Lines?

- High Efficiency: Our machines produce more briquettes per hour with minimal energy waste.

- Customizable Designs: We adapt machines to local raw materials and production needs.

- Durability: Built to withstand continuous operation in tough conditions.

By investing in a complete charcoal making machine in South Africa, producers can scale up production, reduce costs, and meet market demand effectively.

Why South Africa is a Key Market for Ball Briquette Machines?

South Africa has a thriving charcoal industry, driven by:

- High demand for affordable cooking fuel

- Government push for sustainable energy solutions

- Abundance of biomass waste (wood, coconut shells, etc.)

However, traditional charcoal production is inefficient and polluting. The ball briquette machine offers a cleaner, more profitable alternative.

Challenges in the South African Market (and How Weiwa Solves Them)

- Moisture issues? → Our machines include drying solutions.

- Irregular raw materials? → We customize feeding and crushing systems.

- Need for automation? → Weiwa offers fully automated production lines.

Our charcoal making machine in South Africa is designed to overcome local challenges while maximizing output.

How Weiwa Machinery Supports South African Clients?

https://youtu.be/htc-TcpcNIA

At Weiwa Machinery, we don’t just sell machines—we provide end-to-end solutions:

30+ Years of Experience in briquette and charcoal machinery

Professional After-Sales Team (installation, training, maintenance)

Customized Designs & Site Planning (we adapt to your needs)

Free Consultation & Quotation (contact us for a tailored solution)

We understand that every client has unique requirements, which is why we offer bespoke solutions, including:

- Machine sizing based on production goals

- Blueprints for factory layout

- Ongoing technical support

Why Choose Weiwa’s Ball Briquette Machine for Your South African Business?

The ball briquette machine market in South Africa is expanding rapidly, and Weiwa Machinery is at the forefront of this growth. Our high-efficiency, durable, and customizable machines help clients produce more charcoal briquettes with less effort and cost.

Whether you need a standalone ball briquette machine or a complete charcoal production line, Weiwa provides:

✔ Reliable performance

✔ Expert support

✔ Competitive pricing

Ready to start your charcoal briquette business in South Africa? Contact Weiwa Machinery today for a free consultation and quote.

About Weiwa Machinery

With over 30 years of experience in manufacturing briquette and charcoal machines, Weiwa Machinery is a trusted name in the industry. We offer:

Professional after-sales service

Customized designs & drawings

Site planning & installation support

Global reach, including South Africa

Contact us today to discuss your needs and get a personalized quote for your charcoal production line in South Africa.

Wechat

Wechat

+8613838093177

+8613838093177