In the thriving palm oil industries of Indonesia and Malaysia, where vast plantations fuel global demand for edible oils, a significant challenge has emerged alongside production success. The processing of oil palm generates large volumes of waste materials — including palm fiber, palm kernel shells (PKS), and palm shell — that, until recently, were often underutilized or simply discarded. These by-products, while once considered waste, are now recognized as valuable raw materials for producing high-quality charcoal, particularly biochar, through advanced carbonization technology.

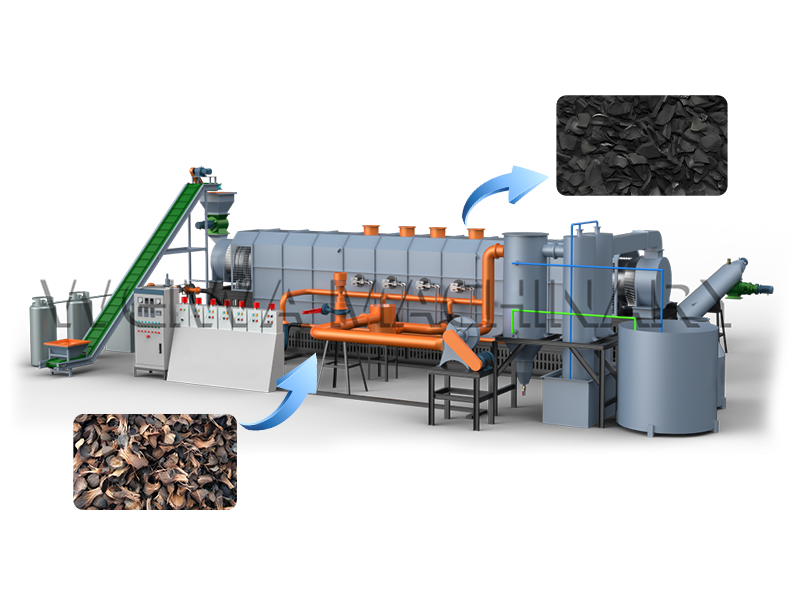

At Weiwa Machinery, with over thirty years of expertise in manufacturing biomass processing equipment, we have developed an innovative solution: the Fourth Generation Continuous Carbonization Furnace with a Secondary Combustion Chamber. This state-of-the-art machinery enables palm oil producers in Indonesia, Malaysia, and beyond to convert their waste into profitable, eco-friendly charcoal products — including biochar, charcoal briquettes, and more.

The Challenge of Palm Waste in Indonesia and Malaysia

Indonesia and Malaysia dominate the global palm oil market, together accounting for over 85% of worldwide production. While this industry brings substantial economic benefits, it also produces massive amounts of biomass residues — namely palm fiber, palm kernel shells (PKS), and palm shell — as by-products of the oil extraction process.

These residues were traditionally either burned in the open, contributing to air pollution and greenhouse gas emissions, or stockpiled, leading to storage challenges and fire hazards. However, with growing environmental regulations and a rising focus on sustainability, there is an urgent need for efficient, eco-friendly methods to manage and repurpose these materials.

This is where continuous carbonization technology comes into play — transforming what was once waste into a valuable commodity.

What is a Continuous Carbonization Furnace?

A continuous carbonization furnace is an industrial machine designed to thermally decompose biomass materials in an oxygen-limited environment, converting organic substances into charcoal (also known as biochar or carbonized biomass). Unlike traditional batch carbonization methods, which require frequent loading and unloading, continuous carbonization furnaces operate non-stop, allowing for higher efficiency, consistent output, and lower labor costs.

At Weiwa Machinery, we have engineered the Fourth Generation Continuous Carbonization Furnace, specifically tailored to process palm oil waste such as palm fiber, palm kernel shells (PKS), and palm shell. Our system incorporates several advanced features that set it apart from earlier models and competitors’ equipment.

Introducing the Fourth Generation Continuous Carbonization Furnace

Our latest Fourth Generation Continuous Carbonization Furnace represents a major leap forward in biomass carbonization technology. Designed with the specific needs of palm oil producers in mind, this furnace offers:

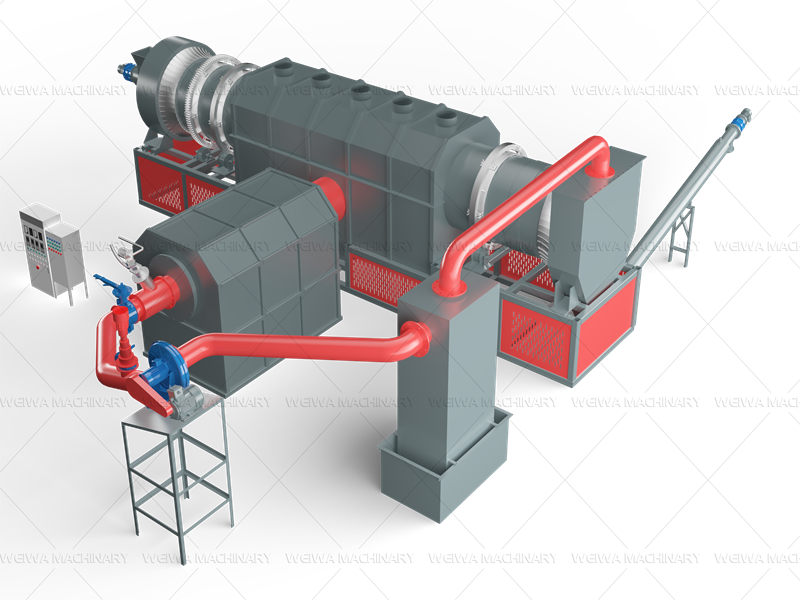

1. Integrated Secondary Combustion Chamber

One of the most important upgrades in our fourth-generation model is the inclusion of a secondary combustion chamber. This component ensures that the volatile gases released during the carbonization process are fully combusted, significantly improving thermal efficiency and reducing harmful emissions.

The secondary combustion chamber allows for cleaner operation, meeting stringent environmental standards in Indonesia, Malaysia, and export markets. It also recovers heat energy, which can be reused within the system, enhancing overall energy efficiency and reducing operational costs.

2. Anti-Clogging Pipeline Design

A common issue in many carbonization systems is pipeline blockage caused by tar, ash, or condensed vapors. Our engineers have tackled this problem head-on by redesigning the internal piping structure to ensure smoother gas flow and prevent buildup.

This anti-clogging pipeline system minimizes maintenance downtime, enhances operational reliability, and ensures a steady flow of carbonized material — making the entire carbonization process more seamless and efficient.

3. High Capacity & Continuous Operation

The fourth-generation furnace is built for industrial-scale operations, capable of processing large volumes of palm shell, palm fiber, and PKS continuously. This makes it ideal for palm oil mills and biomass processing plants that generate waste in high quantities daily.

With continuous feeding and discharging mechanisms, operators can achieve uninterrupted production, maximizing throughput and profitability.

The Carbonization Process Explained

Turning palm oil waste into valuable biochar involves a carefully controlled carbonization process. Here’s how it works when using our continuous carbonization furnace:

Step 1: Raw Material Preparation

The process begins with the collection of palm oil by-products, primarily palm shell, palm fiber, and palm kernel shells (PKS). These materials are first screened to remove impurities and then fed into the carbonization furnace using an automated conveyor system.

Step 2: Drying & Preheating

Before carbonization begins, the raw materials pass through a drying stage where excess moisture is removed. This pre-treatment step ensures more efficient carbonization and higher-quality charcoal output.

Step 3: Carbonization in the Furnace

Once dried, the materials enter the main carbonization chamber, where they are subjected to high temperatures (typically between 400°C and 600°C) in an oxygen-deprived environment. Under these conditions, the organic compounds in the biomass decompose, leaving behind solid carbon — or charcoal.

The entire carbonization process is continuous, with raw materials fed in one end and carbonized charcoal discharged from the other, ensuring a steady production flow.

Step 4: Gas Treatment & Energy Recovery

As the biomass carbonizes, it releases volatile gases and tars. In our system, these by-products are directed to the secondary combustion chamber, where they are burned off to generate additional heat. This not only reduces emissions but also recycles energy back into the system, improving overall efficiency.

Step 5: Charcoal Collection

The resulting biochar is collected at the discharge end of the furnace. This charcoal is highly porous, rich in carbon, and has a wide range of applications — from soil amendment and water filtration to fuel production.

From Biochar to Charcoal Briquettes

While biochar itself is a valuable product, many of our clients choose to further process it into charcoal briquettes using our complementary charcoal briquette machines. Briquetting transforms loose charcoal into uniform shapes — such as round, square, or hexagonal briquettes — that are easier to transport, store, and market.

Applications of Charcoal Briquettes Include:

- Household Fuel: Clean-burning briquettes for cooking and heating.

- Industrial Fuel: Used in boilers, furnaces, and smelting operations.

- BBQ and Hospitality Industry: Premium charcoal for grilling and restaurants.

- Activated Carbon Production: Further processed for water and air purification.

By converting palm waste into marketable charcoal products, producers can tap into multiple revenue streams while contributing to sustainable waste management.

Environmental and Economic Benefits of Carbonizing Palm Waste

The adoption of continuous carbonization technology offers numerous advantages for palm oil producers, local communities, and the environment:

Waste Reduction

Carbonizing palm waste like palm fiber, palm shell, and PKS reduces the volume of biomass that would otherwise be burned or discarded, helping to minimize environmental pollution and land use conflicts.

Renewable Energy Source

The charcoal produced can serve as a renewable energy source, reducing dependence on fossil fuels and supporting sustainable development goals.

Additional Revenue Stream

By converting waste into valuable commodities like biochar and charcoal briquettes, palm oil producers can generate new income, improving the overall profitability of their operations.

Compliance with Environmental Regulations

Our carbonization systems, especially those equipped with secondary combustion chambers, help producers meet stringent environmental standards, avoiding fines and contributing to cleaner air quality.

Why Choose Weiwa Machinery?

With over 30 years of experience in the design, manufacturing, and installation of biomass processing equipment, Weiwa Machinery has established itself as a trusted partner for clients across Asia, Africa, and beyond.

CE/SGS/ISO Certifications and Patented Technologies

At Weiwa Machinery, we are committed to providing high – quality products. Our six – in – a – row charcoal machine is certified by CE, SGS, and ISO, ensuring its compliance with international quality and safety standards. We also have patented technologies that make our machine more efficient and reliable.

Senior Project Consultants

We have a team of senior project consultants who can provide professional advice and guidance to our clients. Whether you are new to the biomass briquette industry or looking to expand your existing business, our consultants can help you design a production plan that meets your specific needs.

Complete After – sales Service

We understand the importance of after – sales service. That’s why we offer complete after – sales support to our clients. Our team of technicians is available to provide on – site support and troubleshooting. We also offer part shipments and on – site field service technician support to ensure that your machine is running smoothly.

Experience in Serving Global Customers

We have more than 130 customers in over 130 countries, including Indonesia, India, Malaysia, and many others. Our experience in serving global customers has given us the expertise to understand the different needs and requirements of the market. We can design different production plans according to different raw materials and different capacities of our clients.

A Sustainable Future Starts with Smart Waste Management

The palm oil industry in Indonesia and Malaysia has reached remarkable heights, but its future sustainability depends on how effectively it manages its by-products. With our Fourth Generation Continuous Carbonization Furnace, Weiwa Machinery offers a smart, eco-friendly, and profitable solution for converting palm fiber, palm shell, and palm kernel shells (PKS) into valuable biochar and charcoal briquettes.

By investing in advanced carbonization technology, palm oil producers can not only solve their waste management challenges but also contribute to a greener planet while unlocking new sources of revenue.

Let Weiwa Machinery be your partner in building a more sustainable and profitable future.

Contact Weiwa Machinery Today

With over 30 years of industry experience, a professional after-sales team, and a commitment to delivering customized solutions, Weiwa Machinery is your trusted partner in biomass carbonization. From equipment design and planning to installation and training, we’re here to support your journey toward sustainable palm waste utilization.

Contact us now to get a quote or learn more about our continuous carbonization furnace, charcoal briquette machine, and other biomass solutions

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177