The Need for Efficient Carbonization in Seychelles

Seychelles, an archipelago nation in Africa, has been increasingly focusing on sustainable energy solutions and waste management. Traditional charcoal production methods are not only inefficient but also environmentally damaging. This is where continuous carbonization furnaces come into play—offering a cleaner, more productive way to produce charcoal from biomass.

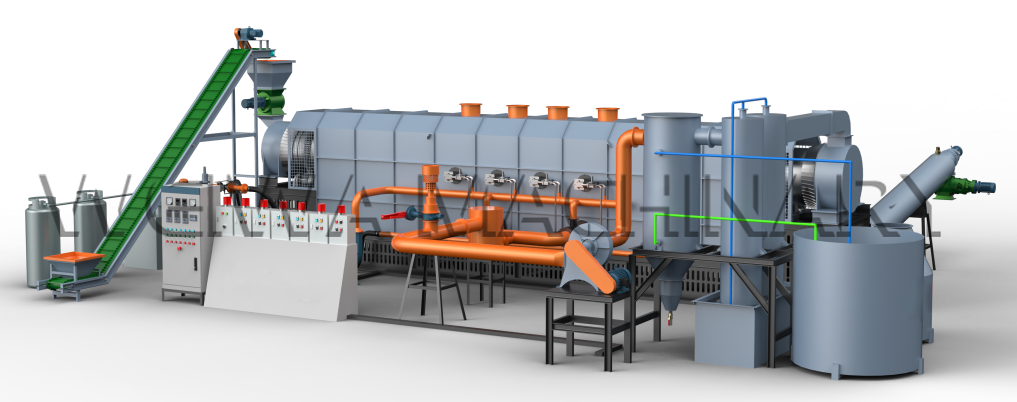

At Weiwa Machinery, we recently conducted a successful test of our 4th-generation continuous carbonization furnace with a secondary combustion chamber for a Seychelles client.

What is a Continuous Carbonization Furnace?

The Basics of Carbonization

Carbonization is the process of converting organic materials (like wood, coconut shells, or agricultural waste) into charcoal through high-temperature heating in an oxygen-limited environment. Unlike traditional batch methods, a continuous carbonization furnace allows for non-stop operation, improving efficiency and reducing downtime.

Why the 4th-Generation Model is a Game-Changer?

Our latest model introduces:

- A secondary combustion chamber – Ensures complete burning of volatile gases, reducing emissions.

- Higher automation – Minimizes manual intervention.

- Energy efficiency – Recovers and reuses heat for better fuel economy.

Live Testing for Seychelles

The Testing Process

Our team shipped the continuous carbonization furnace to Seychelles and conducted a series of trials with different biomass feedstocks, including:

- Coconut shells (abundant in Seychelles)

- Wood chips

- Agricultural residues

The test focused on:

https://youtu.be/-1xX59FEE3o

- Carbonization efficiency (how much charcoal is produced vs. raw material)

- Emission control (how well the secondary combustion chamber works)

- Operational stability (how smoothly the furnace runs continuously)

Key Findings from the Test

High charcoal yield – Up to 35-40% conversion rate from raw biomass.

Low emissions – The secondary combustion chamber burned off harmful gases effectively.

Stable continuous operation – The furnace ran for over 72 hours without issues.

Energy savings – Heat recovery reduced fuel consumption by 20-25%.

Why Continuous Carbonization Furnaces Matter for Africa?

Africa’s Growing Demand for Sustainable Charcoal

Many African nations, including Seychelles, rely on firewood and traditional charcoal, leading to:

- Deforestation

- Air pollution

- Inefficient energy use

A continuous carbonization furnace solves these problems by:

✔ Using waste biomass (coconut shells, sawdust, etc.)

✔ Producing cleaner charcoal

✔ Reducing manual labor

Market Potential in Seychelles & Beyond

Seychelles, with its tropical biomass availability, is an ideal market. Neighboring African countries like Kenya, Tanzania, and Madagascar also show growing interest in modern carbonization solutions.

Weiwa Machinery’s Commitment to Sustainable Carbonization

Our 4th-gen continuous carbonization furnace with a secondary combustion chamber proved to be a reliable, efficient, and eco-friendly solution during the Seychelles trial. The high charcoal yield, low emissions, and stable performance make it a perfect fit for Africa’s evolving energy needs.

At Weiwa Machinery, we don’t just sell machines—we provide sustainable solutions tailored to local needs. Whether you’re in Seychelles or anywhere in Africa, we’re here to help you transition to smarter charcoal production.

About Weiwa Machinery

Weiwa Machinery is a leading manufacturer of biomass carbonization and charcoal-making equipment, specializing in continuous carbonization furnaces, briquette machines, and waste-to-energy solutions. With years of experience in export markets, including Africa, Southeast Asia, and South America, we provide customized, high-efficiency machinery for sustainable charcoal production.

Our R&D team continuously innovates to improve carbonization technology, ensuring our clients get the best performance, durability, and ROI.

Contact us today to learn how our continuous carbonization furnace can benefit your business in Seychelles or beyond.

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177