The Rising Demand for Charcoal Rod Machines in Thailand

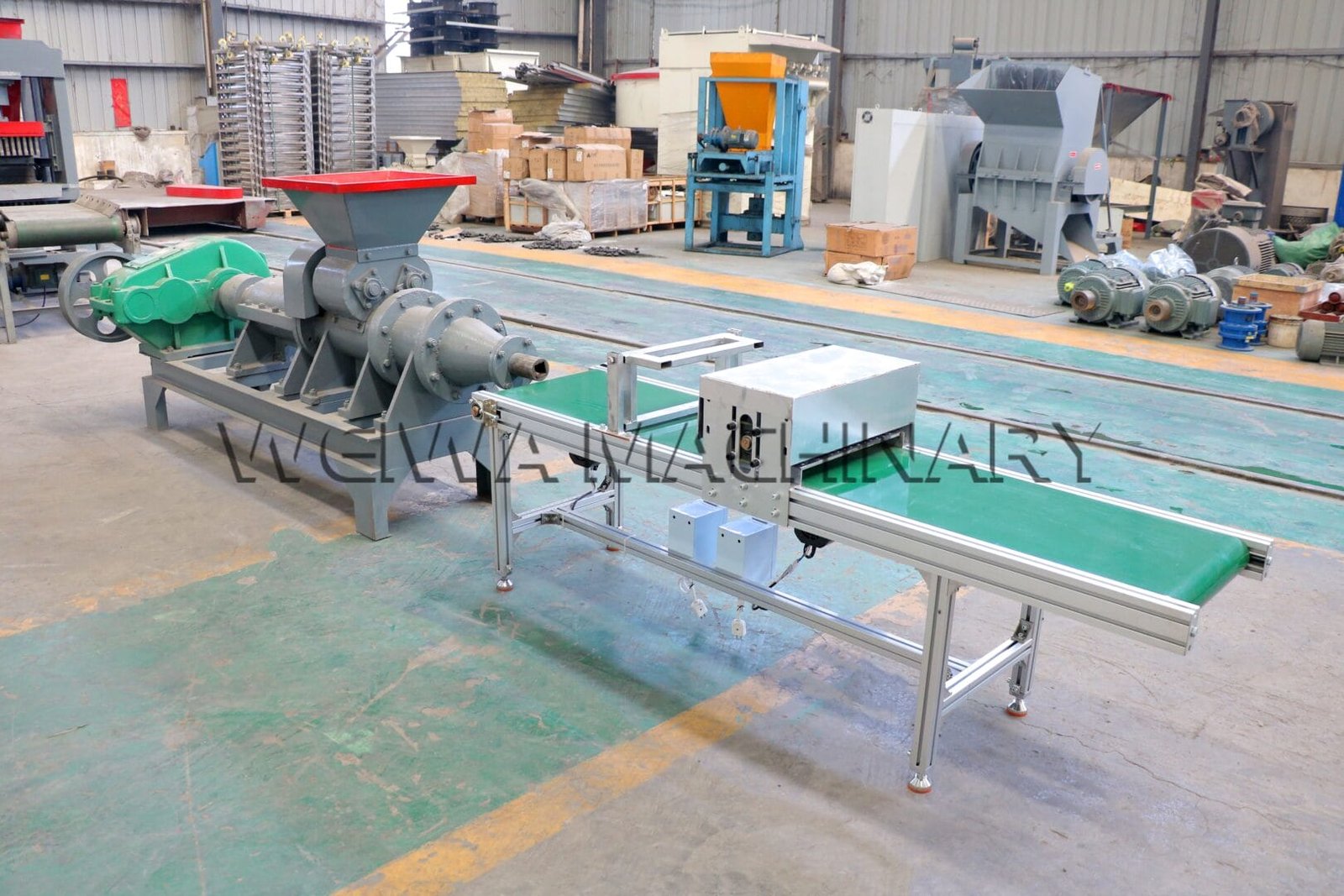

Thailand’s growing reliance on sustainable fuel solutions has propelled the demand for charcoal making machines, particularly rod briquette machines with cutters. As a leading manufacturer, Weiwa Machinery recently conducted comprehensive tests for our charcoal extruder machine with cutter in Thailand, focusing on efficiency, durability, and cost-effectiveness.

Why Thailand Needs Advanced Charcoal Extrusion Technology?

The Shift Toward Biomass Briquettes

Thailand, with its abundant agricultural waste (e.g., coconut shells, wood chips), has increasingly adopted charcoal briquettes as an eco-friendly alternative to traditional charcoal. However, the challenge lies in producing uniform, high-density rods efficiently—this is where our charcoal extruder machine with cutter comes in.

Market Pain Points Addressed by Weiwa’s Machine

- Inconsistent rod lengths? Our built-in cutter ensures precise sizing.

- High production costs? The machine maximizes raw material usage.

- Manual cutting inefficiency? Automation boosts output.

Weiwa’s Charcoal Extruder Machine with Cutter

1. Robust Extrusion Mechanism

Our rod briquette making machine in Thailand uses a screw-based extrusion system to compress biomass into dense rods. The cutter attachment automatically slices the rods to the desired length, eliminating manual labor.

2. Customizable Output

Whether clients need 6mm, 8mm, or 10mm rods, our machine adjusts seamlessly. The cutting speed is synchronized with extrusion to maintain consistency.

3. Energy-Efficient & Low Maintenance

Compared to traditional methods, our charcoal extrude machine in Thailand consumes less power while requiring minimal upkeep—ideal for Thai manufacturers.

On-Site Testing in Thailand

Test Parameters

https://youtu.be/aDp1HzyZVZ8

- Raw Materials Used: Coconut shell charcoal powder, wood sawdust.

- Production Capacity: 600-1200 kg/hour (adjustable).

- Cutter Efficiency: ±1mm precision in rod length.

Why Thai Clients Are Impressed?

✅ Zero jamming issues during continuous operation.

✅ Cutting mechanism reduced post-processing time by 40%.

✅ Smooth, dense rods with high combustion efficiency.

Charcoal Making Machine Price

Why Weiwa’s Pricing Stands Out

While the charcoal making machine price varies globally, Weiwa offers:

- Competitive rates without compromising quality.

- Longer lifespan (8+ years with proper maintenance).

- Local support in Thailand for troubleshooting.

Why Thai Manufacturers Choose Weiwa Machinery?

1. Proven Track Record

We’ve supplied rod briquette machines with cutters to multiple Thai clients, each reporting increased productivity.

2. Tailored Solutions

Unlike generic suppliers, we customize machines based on local biomass availability (e.g., coconut waste in southern Thailand).

3. After-Sales Support

Our team assists with installation, training, and spare parts—ensuring smooth operations.

The Future of Charcoal Briquetting in Thailand

The trial confirmed that Weiwa’s charcoal extruder machine with cutter is a game-changer for Thailand’s charcoal industry. With high efficiency, precise cutting, and cost-effective production, it’s the ideal choice for manufacturers aiming to scale sustainably.

Contact Weiwa Machinery today to learn more about our rod briquette making machine in Thailand and how we can optimize your production.

About Weiwa Machinery

Since 1990, Weiwa Machinery has been a trusted name in charcoal extrusion and briquetting solutions. Specializing in rod briquette machines with cutters, we serve clients worldwide, including Thailand, with durable, high-performance equipment. Our commitment to innovation, affordability, and customer support makes us the preferred partner for sustainable fuel production.

Wechat

Wechat

+8613838093177

+8613838093177