In recent years, the demand for efficient, eco-friendly fuel alternatives has surged across Southeast Asia, with Indonesia emerging as a key market for charcoal and coal briquetting technologies. As a leading manufacturer of coal briquette machines and charcoal extruder machines, Weiwa Machinery has been at the forefront of this transformation. Our commitment goes beyond merely supplying machinery — we focus on building long-term partnerships by ensuring our equipment consistently meets the evolving needs of our clients.

Understanding the Role of Coal Briquette and Charcoal Extruder Machines

Before diving into the field updates, it’s essential to understand what coal briquette machines and charcoal extruder machines are, and why they are pivotal in today’s energy landscape.

What is a Coal Briquette Machine?

A coal briquette machine is a piece of equipment designed to compress loose coal fines or powder into uniform, dense briquettes. These briquettes are easier to store, transport, and burn more efficiently than raw coal. In many developing regions, including parts of Indonesia, coal briquettes serve as a cleaner and more economical alternative to traditional fuel sources.

Our coal briquette machines utilize high pressure and specialized molds to form briquettes without the need for binders in many cases, although binders can be added depending on the coal type and desired output.

What is a Charcoal Extruder Machine?

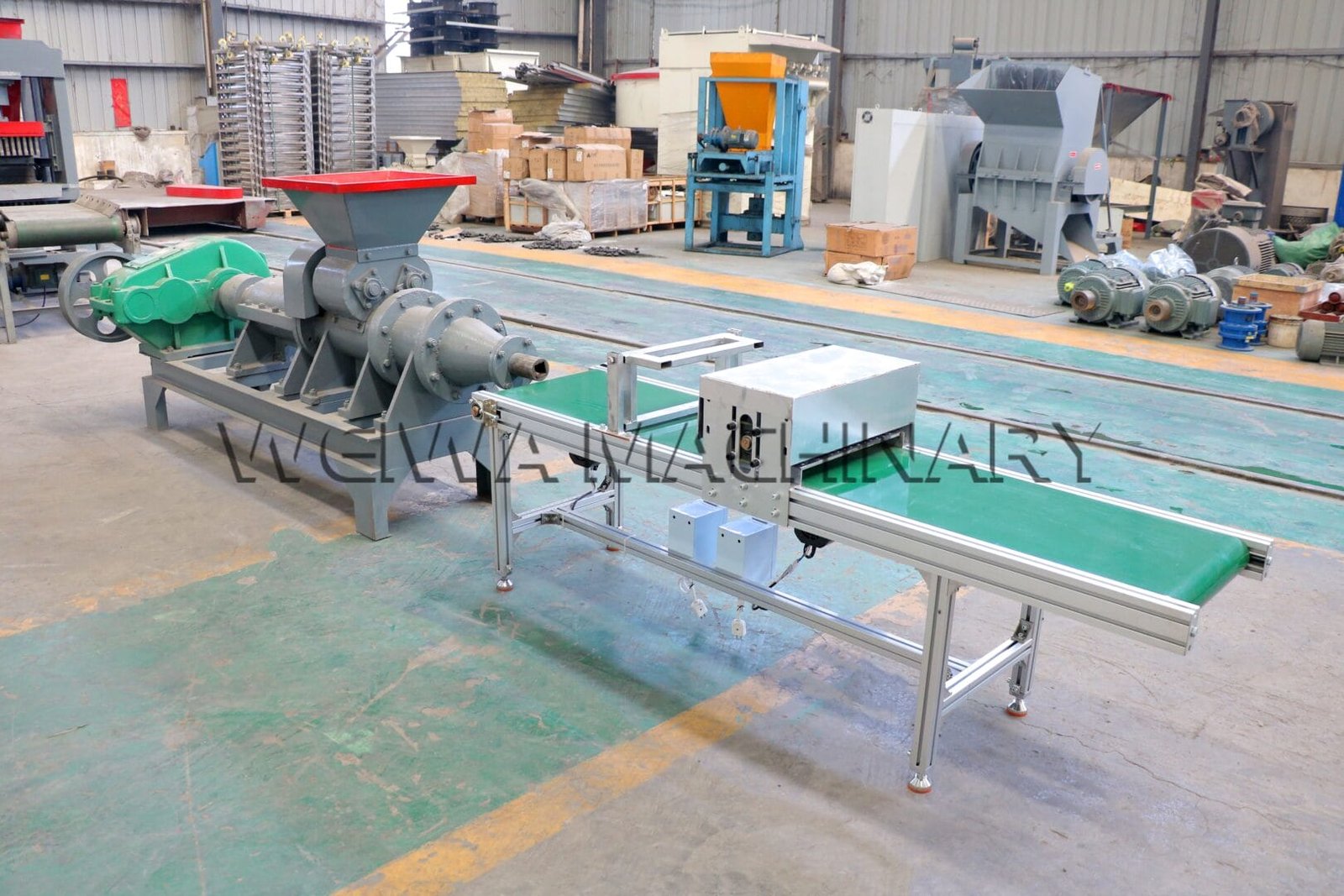

A charcoal extruder machine, often referred to as a charcoal rod extruder or charcoal briquette extruder, is used to produce cylindrical charcoal briquettes or rods from charcoal dust or fine charcoal powder. The extrusion process involves pushing the charcoal material through a die under high pressure to form a continuous rod, which is then cut into desired lengths.

These machines are especially popular among small and medium enterprises (SMEs) involved in BBQ charcoal production, as the resulting products are uniform, easy to handle, and have a longer burning time.

In Indonesia, where charcoal is widely used for cooking, heating, and industrial purposes, both charcoal extruder machines and coal briquette machines play complementary roles in meeting local energy demands sustainably.

Field Observations and Client Interactions

Indonesia has been one of our most strategic markets, not only due to its geographic significance in Southeast Asia but also because of its growing reliance on processed biomass and coal-based fuels. Earlier this year, our team participated in an industry trade show in Jakarta, where we engaged with both new prospects and existing clients. Following the event, we scheduled a series of on-site visits to follow up with our customers, particularly those using our charcoal extruder machine in Indonesia and coal briquette machine for Indonesia applications.

Our goal was clear: to understand how our machines were performing in real-world conditions, identify any operational challenges, and provide tailored solutions to enhance efficiency and output quality.

Challenges Identified in the Field

During our visit, our engineers spent several days at multiple client locations — ranging from small family-run workshops to larger production facilities. One common theme emerged: while our machines were fundamentally sound, certain operational parameters needed adjustment to align with local material properties and environmental conditions.

Material Variability

One of the first issues our engineers encountered was the variability in raw material quality. In some regions, the coal or charcoal fines had higher moisture content or inconsistent particle sizes, which affected the binding and compression characteristics during the briquetting or extrusion process.

For instance, in one location using our charcoal extruder machine, the charcoal dust had a slightly higher moisture level than recommended. This led to occasional blockages in the extrusion die and reduced the overall density of the produced rods.

Operational Technique

Another challenge was related to operational technique. Some operators were not fully utilizing the adjustable settings on the machines, such as pressure control, die selection, and feed rate. These settings are crucial for optimizing output based on the specific material being used.

Our team noticed that in some cases, clients were using generic settings provided during installation, without accounting for local variations in raw materials or ambient humidity.

Machine Wear and Maintenance

Regular maintenance is critical for the longevity and efficiency of any mechanical equipment. During our visit, we found that while most clients performed basic maintenance, there were opportunities to improve the frequency and precision of component inspections — particularly for wear parts like the extrusion screw, die, and pressure rollers in the coal briquette machine.

On-Site Adjustments and Machine Optimization

Equipped with firsthand insights, our engineers got to work. The beauty of Weiwa Machinery’s approach lies in our ability to provide customized, on-site technical support — ensuring that every machine operates at its full potential, regardless of location or material specifics.

Recalibrating Machine Settings

For the charcoal extruder machine experiencing moisture-related issues, our engineers adjusted the compression ratio and recommended pre-drying the charcoal dust before feeding it into the machine. They also modified the die design slightly to accommodate the material flow characteristics better, resulting in smoother extrusion and fewer blockages.

Similarly, for the coal briquette machines, we tweaked the pressure settings and recommended a slight alteration in the roller gap to improve briquette density and reduce breakage during handling.

Training and Knowledge Transfer

Beyond mechanical adjustments, a significant part of our visit focused on training local operators. Our engineers conducted hands-on sessions to demonstrate how to adjust machine parameters in real-time, how to identify early signs of wear or misalignment, and how to perform routine maintenance tasks effectively.

We also shared best practices for storing and preparing raw materials to ensure consistent input quality, which directly impacts the performance and output of both charcoal extruder machines and coal briquette machines.

Upgrading Key Components

In a couple of cases, we identified worn-out components that were affecting machine efficiency. Rather than simply repairing these parts, we worked with the clients to upgrade to more durable, high-performance components — such as hardened steel rollers and heat-treated extrusion screws — ensuring a longer service life and reduced downtime.

Improved Performance and Client Satisfaction

The results of our interventions were immediate and impactful. Across all visited sites, clients reported noticeable improvements in machine performance, including:

- Higher throughput rates

- More consistent briquette and rod quality

- Reduced material waste

- Lower energy consumption per unit produced

- Fewer operational interruptions

One client, who had been struggling with frequent blockages in their charcoal extruder machine, shared that after our adjustments, they were able to run their production line uninterrupted for 12-hour shifts — a significant improvement from their previous 6–8 hour cycles.

Another client using our coal briquette machine for Indonesia operations noted that the adjusted pressure settings resulted in briquettes with a higher calorific value, making them more attractive to buyers in the local market.

The Potential of Coal Briquette and Charcoal Extruder Machines in Southeast Asia

Indonesia’s energy landscape is undergoing a gradual shift. While the country is rich in natural resources, including oil, gas, and coal, there is a growing emphasis on sustainable and affordable fuel alternatives — particularly in rural and semi-urban areas.

Coal briquettes and charcoal briquettes offer a practical solution for households, small industries, and even larger commercial operations looking for cost-effective, cleaner-burning fuels. The demand is further driven by government initiatives aimed at reducing deforestation (through sustainable charcoal production) and improving energy efficiency.

In this context, the role of reliable, efficient machinery — such as our coal briquette machines and charcoal extruder machines — cannot be overstated. These machines empower local entrepreneurs and businesses to produce high-quality fuel products that meet both economic and environmental standards.

Southeast Asia, with its abundant biomass resources and growing energy needs, represents a massive opportunity for expansion. Countries like Malaysia, Vietnam, the Philippines, and Thailand are also showing increasing interest in briquetting technologies, creating a ripple effect that extends far beyond Indonesia.

Why Choose Weiwa Machinery?

At Weiwa Machinery, we don’t just sell machines — we provide comprehensive solutions that empower our clients to succeed. Our commitment to quality, innovation, and customer support has made us a trusted partner in the briquetting and extrusion industry.

Here’s what sets us apart:

- Customized Solutions: We understand that every client’s needs are unique. That’s why we offer tailored machine configurations to match specific production goals and material types.

- Technical Expertise: Our team of engineers brings years of hands-on experience in designing, installing, and optimizing briquette and extruder machines. We’re always just a call away, ready to provide on-site or remote support.

- Global Reach, Local Touch: With a presence in key markets across Asia, Africa, and beyond, we combine global manufacturing standards with localized customer service.

- Continuous Improvement: Feedback from our clients drives our innovation. We regularly update our machine designs and processes based on real-world usage data and emerging industry trends.

From our state-of-the-art manufacturing facilities to our dedicated after-sales support team, every aspect of Weiwa Machinery is geared toward one goal: helping our clients produce more, waste less, and thrive in their markets.

Conclusion

Our recent visit to Indonesia was more than just a routine follow-up — it was a testament to our commitment to excellence and customer success. By listening to our clients, understanding their challenges, and providing targeted solutions, we were able to transform their operations and help them achieve new levels of efficiency and productivity.

As the demand for coal briquette machines and charcoal extruder machines continues to grow across Southeast Asia, we’re excited to play a leading role in shaping the future of sustainable fuel production. Whether you’re an established producer or just starting out, Weiwa Machinery is here to support your journey with reliable equipment, expert guidance, and unwavering dedication.

Contact us today to learn more about our range of briquetting and extrusion solutions — and discover how we can help you turn challenges into opportunities.

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177