The Rising Demand for Sustainable Charcoal in Qatar

As Qatar accelerates its sustainability initiatives, the demand for efficient, eco-friendly charcoal making machines has surged. Traditional charcoal production methods are being replaced by advanced technologies like the continuous carbonization furnace, which offers higher yield, lower emissions, and continuous operation. At Weiwa Machinery, we recently conducted a successful rice husk carbonization trial for a Qatari client using our continuous carbonization furnace for Qatar, demonstrating its potential in the region’s emerging biomass energy sector.

What is a Continuous Carbonization Furnace?

How It Works: A Scientific Approach to Charcoal Production?

https://youtu.be/tmIkWfBk_CI

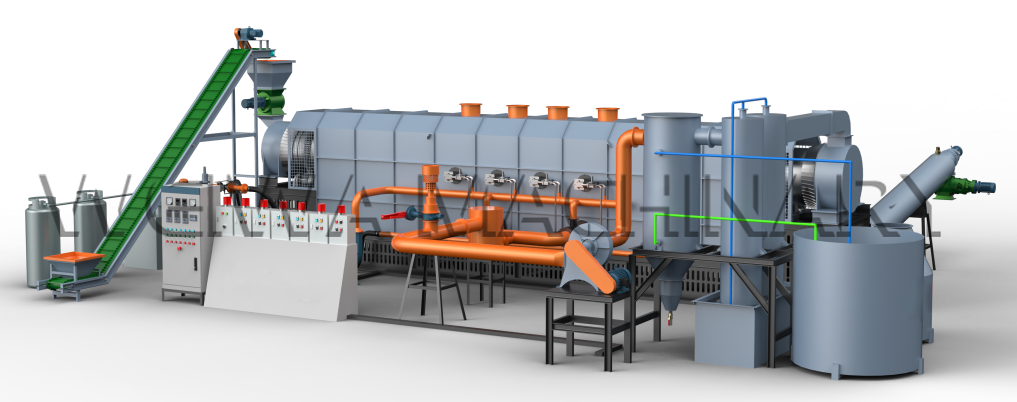

A continuous carbonization furnace is an advanced charcoal making machine that processes biomass (like rice husk, wood, or coconut shells) into high-quality charcoal through high-temperature pyrolysis (decomposition without oxygen). Unlike traditional charcoal kilns, which operate in batches, our continuous carbonization furnace for Qatar allows non-stop feeding and discharging, maximizing efficiency.

Key Features:

- Continuous operation (no downtime between batches)

- High carbonization rate (up to 90% conversion efficiency)

- Low emissions (equipped with smoke purification systems)

- Energy-saving design (utilizes waste heat for preheating)

Why Qatar Needs Continuous Carbonization Technology?

Qatar, with its limited forestry resources but abundant agricultural waste (like rice husk from imported feed), requires a sustainable charcoal solution. Our continuous carbonization furnace is perfect for converting local biomass into renewable charcoal for industrial, agricultural, and domestic use.

Weiwa’s Rice Husk Carbonization Trial in Qatar

The Testing Process: From Raw Material to High-Quality Charcoal

For our Qatari client, we conducted a pilot test using rice husk—a widely available agricultural byproduct. The trial aimed to evaluate:

- Carbonization efficiency (how much charcoal is produced)

- Energy consumption (fuel and power usage)

- Emission control (smoke and particulate matter management)

- Machine durability (continuous operation stability)

Results: Surpassing Expectations

- High Charcoal Yield (≈35-40% of input weight)

- The continuous carbonization furnace converted rice husk into dense, high-calorific charcoal suitable for BBQs, industry, and agriculture.

- The charcoal had low ash content (≈5-8%), making it cleaner than traditional charcoal.

- Stable Continuous Operation (24+ Hours Without Interruption)

- Unlike batch charcoal kilns, our furnace maintained consistent temperature (450–600°C) without manual intervention.

- Minimal Emissions (Equipped with Advanced Purification)

- The system included a smoke recycling mechanism, turning harmful gases into usable heat, reducing environmental impact.

- Energy Efficiency (Self-Sustaining Process)

- The furnace reuses waste heat to preheat incoming raw materials, cutting energy costs by up to 30%.

Continuous Carbonization Furnace vs. Traditional Charcoal Kiln

| Feature | Continuous Carbonization Furnace | Traditional Charcoal Kiln |

|---|---|---|

| Operation | Non-stop, automated | Batch-based, manual |

| Efficiency | 35-40% charcoal yield | 20-30% yield |

| Emissions | Low (with purification) | High (open burning) |

| Energy Use | Self-sustaining (waste heat reuse) | High fuel consumption |

| Maintenance | Low (durable steel construction) | Frequent repairs |

Conclusion: The continuous carbonization furnace is clearly superior for Qatar’s industrial needs, offering higher output, lower emissions, and continuous productivity.

Why Qatar is the Perfect Market for Weiwa’s Continuous Carbonization Furnace?

1. Growing Demand for Sustainable Charcoal

Qatar imports most of its charcoal, but with rising environmental concerns, the government is promoting local biomass utilization. Rice husk, a byproduct of animal feed imports, is an untapped resource.

2. Government Support for Green Technology

Qatar’s National Vision 2030 emphasizes renewable energy and waste reduction, making our continuous carbonization furnace an ideal solution.

3. Agricultural & Industrial Applications

- BBQ & Hookah Charcoal (premium market)

- Industrial Fuel (steel, cement industries)

- Agricultural Use (soil enrichment, water filtration)

Weiwa Machinery’s Commitment to Qatar’s Carbonization Future

Our rice husk carbonization trial proved that the continuous carbonization furnace for Qatar is not just a machine—it’s a sustainable solution for the region’s energy needs. With high efficiency, low emissions, and continuous operation, it’s the future of charcoal making machines in Qatar.

About Weiwa Machinery

At Weiwa Machinery, we specialize in advanced biomass carbonization solutions, including continuous carbonization furnaces, charcoal making machines, and eco-friendly pyrolysis systems. With years of experience in exporting to the Middle East, we provide customized, high-performance machinery tailored to local needs.

Our Services:

- Turnkey carbonization solutions

- On-site testing & training

- After-sales support & spare parts

Contact us today to learn how our continuous carbonization furnace can revolutionize your charcoal production in Qatar or beyond.

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177