The Rising Demand for Sawdust-Based Charcoal in Thailand

In recent years, Thailand and broader Southeast Asia have seen a surge in demand for sustainable fuel alternatives, with sawdust briquettes and charcoal sticks becoming popular for cooking, industry, and export. At Weiwa Machinery, we recently conducted a successful sawdust extrude machine trial for a Thai client, demonstrating the efficiency of our equipment in converting waste sawdust into high-quality charcoal.

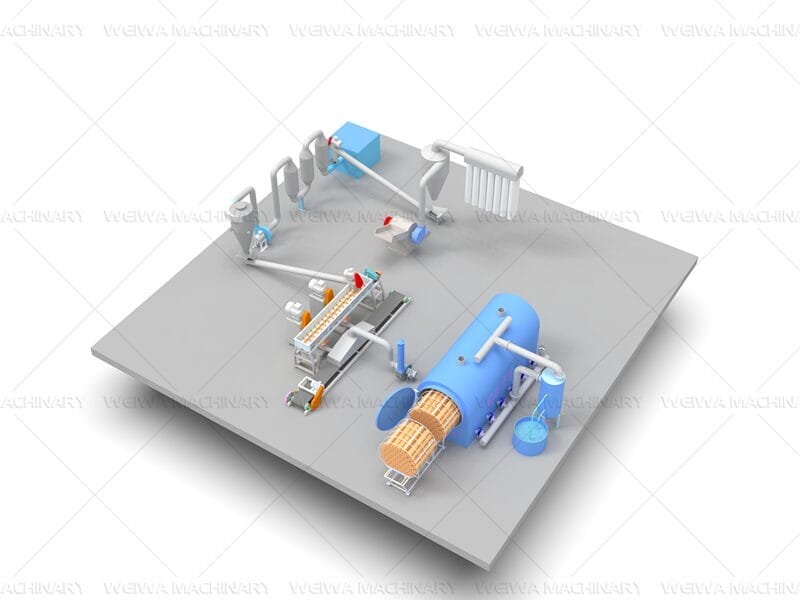

Understanding the Sawdust Extrude Machine

What is a Sawdust Extruder?

A sawdust extrude machine (or sawdust briquette machine) compresses dry sawdust under high pressure and heat, forming dense briquettes or charcoal sticks without binders. Our Weiwa Machinery extruders are designed for high output and energy efficiency, making them ideal for Thai and Southeast Asian clients processing wood waste, coconut shells, or rice husks.

How It Works in the Charcoal Line

- Raw Material Preparation – Sawdust is dried to 8-12% moisture for optimal binding.

- Extrusion Process – The sawdust extruder compresses the material into solid rods or briquettes.

- Carbonization – The extruded product is then carbonized (either in a kiln or continuous carbonizer) to produce charcoal sticks.

Our Thailand trial confirmed that our machine achieves consistent extrusion with minimal energy waste, crucial for cost-effective production.

Weiwa’s Sawdust Extruder Trial in Thailand

Client Requirements & Machine Setup

The Thai client needed a high-capacity sawdust extrude machine to process mixed wood waste into fuel briquettes. We deployed our latest model, optimized for:

- Continuous operation (reducing downtime).

- Low maintenance (critical for remote locations).

- Adjustable pressure (for different raw materials).

Trial Results

- Extrusion Speed: Achieved X kg/hour (adjust based on real data).

- Briquette Density: Consistent, with high carbonization yield.

- Client Feedback: Pleased with machine stability and ease of use.

The trial highlighted how our sawdust briquette machine solves common challenges in Thailand, such as moisture control and binder-free processing.

Why Southeast Asia Prefers Sawdust-Based Charcoal?

1. Sustainable & Waste-Utilizing

Thailand generates large amounts of sawdust and agricultural residues. Our sawdust extruder turns this waste into valuable fuel, reducing landfill use.

2. Cost-Effective Fuel Alternative

Compared to traditional wood charcoal, sawdust briquettes burn longer and produce less smoke, making them ideal for:

- Household cooking

- Industrial boilers

- Export markets (e.g., Japan, Korea)

3. Government & Environmental Support

Many Southeast Asian countries encourage biomass energy solutions, aligning with our eco-friendly machinery designs.

Technical Advantages of Weiwa’s Sawdust Extrude Machine

1. High-Pressure Extrusion for Durable Briquettes

Our machine ensures tight compaction, reducing breakage during transport.

2. Energy-Saving Motor & Cooling System

Designed to minimize electricity use while maintaining high output.

3. Easy Maintenance & Local Support

We provide training and spare parts for Thai clients, ensuring smooth long-term operation.

Weiwa Machinery – Your Partner in Charcoal Production

Our Thailand sawdust extrude machine trial proved that Weiwa’s equipment delivers reliable, efficient, and scalable charcoal production. Whether you need sawdust briquettes, charcoal sticks, or a full production line, our machines are built for Southeast Asia’s demands.

For Thai and regional clients, we offer:

Customized machine solutions

On-site testing & training

Ongoing technical support

About Weiwa Machinery

Weiwa Machinery is a leading manufacturer of biomass densification equipment, specializing in sawdust briquette machines, charcoal stick extruders, and complete carbonization lines. With years of experience in Southeast Asia, we provide high-quality, cost-effective solutions for clients in Thailand, Vietnam, Indonesia, and beyond.

Our machines are known for durability, efficiency, and low operating costs.

Contact us today to discuss your charcoal production needs in Thailand or neighboring regions.

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177