The Rising Demand for Sustainable Charcoal Production

In recent years, the global demand for biochar and high-quality charcoal has surged, driven by its applications in agriculture, energy, and environmental sustainability. Indonesia, with its abundant palm fiber waste, presents a unique opportunity for efficient biomass carbonization.

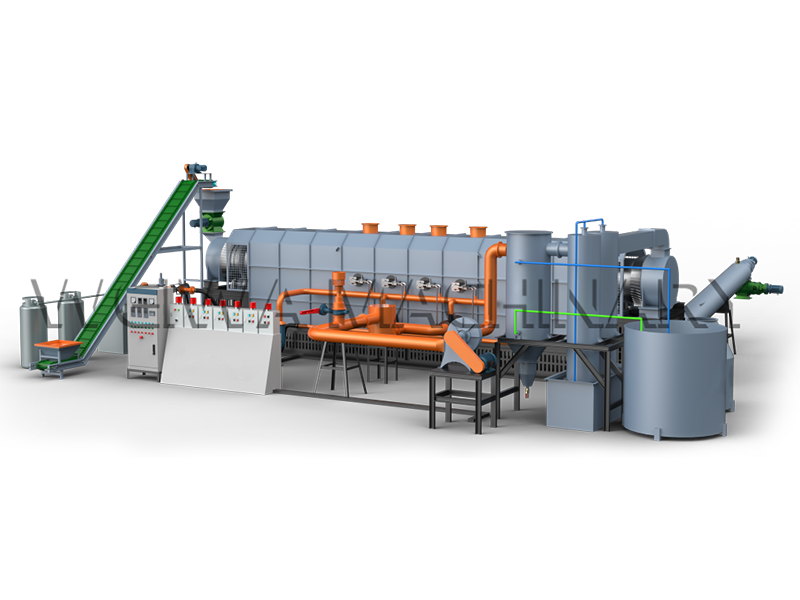

At Weiwa Machinery, we recently completed the delivery of a complete continuous carbonization furnace production line to an Indonesian client, specializing in converting palm fiber into charcoal briquettes using a honeycomb coal press machine. This project highlights our expertise in designing continuous carbonization furnaces for palm fiber, tailored for the Indonesian market.

Inefficient Carbonization Methods for Palm Fiber

Before partnering with Weiwa, our Indonesian client relied on traditional batch carbonization methods, which were:

- Time-consuming (long cooling and heating cycles)

- Labor-intensive (manual feeding and unloading)

- Low-yield (inconsistent carbonization quality)

Additionally, Indonesia’s palm fiber waste (a byproduct of palm oil production) was underutilized, despite its high potential for biochar production.

Our client needed a continuous, automated solution that could:

✔ Process palm fiber efficiently

✔ Produce high-quality charcoal briquettes

✔ Operate 24/7 with minimal supervision

A Complete Continuous Carbonization Furnace Production Line

To meet these requirements, Weiwa designed and delivered a fully integrated production line, including:

1. Continuous Carbonization Furnace for Palm Fiber

Our continuous carbonization furnace is specifically engineered for biomass materials like palm fiber, ensuring:

- High carbonization efficiency (up to 90% conversion rate)

- Stable temperature control (preventing material damage)

- Automated feeding and discharging (reducing labor costs)

This furnace is ideal for Indonesia’s tropical climate, ensuring durable performance even in high-humidity conditions.

2. Honeycomb Coal Press Machine for Briquette Production

After carbonization, the palm fiber charcoal is transformed into high-density briquettes using our honeycomb coal press machine. This ensures:

- Uniform shape and size (better combustion efficiency)

- Higher market value (briquettes are preferred over loose charcoal)

- Reduced transportation costs (compact storage)

3. Complete Production Line Integration

Our team in Indonesia handled:

- Site planning & layout design (optimized workflow)

- Equipment installation & training (ensuring smooth operation)

- After-sales support (responsive maintenance)

This turnkey solution allowed our client to start production quickly with minimal downtime.

Why Continuous Carbonization Furnaces Are the Future?

Unlike traditional batch carbonization, continuous carbonization furnaces offer:

Higher Efficiency

- Non-stop operation (no need for repeated cooling/heating)

- Faster processing (higher throughput)

Better Quality Control

- Uniform carbonization (consistent charcoal quality)

- Lower emissions (environmentally friendly)

Cost-Effective for Large-Scale Production

- Reduced labor costs (automated feeding)

- Lower energy consumption (optimized heat recycling)

For Indonesian clients, this means higher profits and sustainable biomass utilization.

Palm Fiber Is The Ideal Raw Material for Biochar in Indonesia

Indonesia produces millions of tons of palm fiber waste annually, much of which goes unused. Our client recognized its potential as a low-cost, high-yield carbonization material because:

- High carbon content (excellent for charcoal production)

- Abundant supply (readily available near palm oil mills)

- Low processing cost (minimal preprocessing needed)

By converting this waste into biochar and charcoal briquettes, our client not only generates revenue but also contributes to waste reduction and sustainability.

Why Indonesian Clients Choose Weiwa Machinery?

Our success in Indonesia is built on:

30+ Years of Expertise

With decades of experience in carbonization technology, we understand the unique needs of different markets.

Customized Solutions

Every client has different requirements—we provide tailored designs, drawings, and layout planning to maximize efficiency.

Complete Turnkey Delivery

From equipment manufacturing to on-site installation & training, we handle everything.

Reliable After-Sales Support

Our professional service team ensures smooth operations with quick maintenance and troubleshooting.

Partner with Weiwa for Your Carbonization Needs

Our project in Indonesia proves that Weiwa Machinery’s continuous carbonization furnaces are the best solution for palm fiber biochar production. With high efficiency, low operating costs, and excellent scalability, our technology helps clients maximize profits while contributing to sustainability.

If you’re looking for a trusted partner for continuous carbonization furnaces in Indonesia—or anywhere else—contact Weiwa Machinery today for a consultation and customized quote.

About Weiwa Machinery

With over 30 years of experience in charcoal and carbonization equipment manufacturing, Weiwa Machinery is a leading provider of continuous carbonization furnaces, briquette machines, and complete production lines.

Our professional after-sales team ensures 24/7 support, custom design services, and on-site installation assistance. Whether you need a continuous carbonization furnace for palm fiber, wood, or other biomass, we deliver high-quality, reliable solutions tailored to your needs.

Contact us today for a free consultation and quotation!

- Mob:+8613838093177

- Whatsapp:+8613838093177

- E-Mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177