Wood charcoal making machine is used to solve the waste wood disposal issues in the forestry and wood processing industry. Through high-temperature and low-oxygen pyrolysis technology, this machine transforms waste wood into economically valuable charcoal. Todo el proceso de transformación garantiza la amistad ambiental y la contaminación mínima. Como uno de los líderes en el campo de reciclaje de residuos, Weiwa Machinery Group offers a one-stop wood recycling solution for your maximum convenience.

With the increasing use of wood, approximately 15 million tons of waste wood are generated globally every year. Sin embargo, menos que 20% of wood resources are recycled.

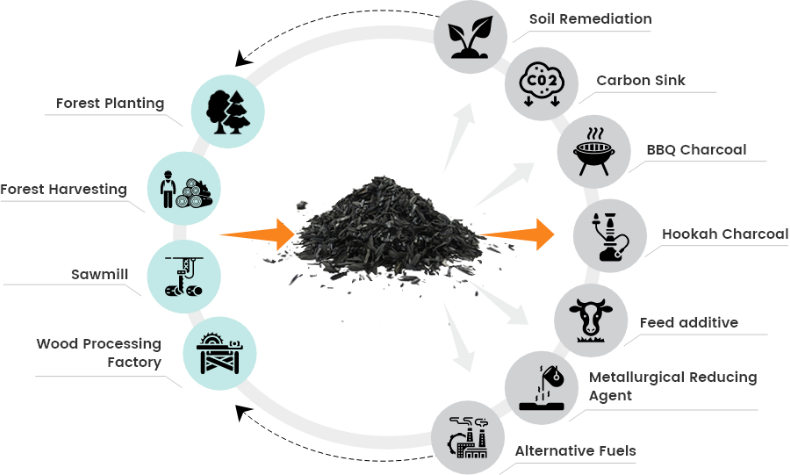

Application of Wood Charcoal

Charcoal can be used for domestic combustion, calderas, barbacoas, calefacción de chimenea, centrales eléctricas y otros aspectos.

Además, Debido a su estructura microporosa única y su capacidad de súper adsorción, Se usa ampliamente en muchos campos, como la comida., farmacia, industria química, metalurgia, defensa nacional, Agricultura y protección del medio ambiente.

Circular Application of Wood Charcoal

Principio de trabajo de carbonización

Los materiales de biomasa que contienen carbono se someten a destilación seca y calentamiento sin oxígeno, y están pirolizados en gas combustible, alquitrán y carbón a través de la eliminación de la humedad.

Se puede recolectar y utilizar gas inflamable como combustible.

Tar se puede usar después de la separación y la purificación.

Nota: En resumen, El principio de funcionamiento de la carbonización es el mismo, Pero según diferentes materiales, Diferentes requisitos de productos terminados y requisitos de salida, El equipo seleccionado también es diferente. Participar en la industria de la carbonización, Es particularmente importante elegir equipos de carbonización adecuados.

Wood Charcoal Briquette Production Line raw materials

Wood charcoal briquette production line has a wide range of raw materials,como troncos de madera, bambú, cáscara de coco, conchas de palma, chips de madera, cáscaras de arroz, cáscara de nueces, Conchas de nogal y varias materias primas de biomasa.

Wood Charcoal Briquette Production Line product description

A.Drum chipper is a special equipment for producing all kinds of high-quality wood chips. It can cut logs and small-diameter wood into high-quality wood chips with uniform size and flat cuts.

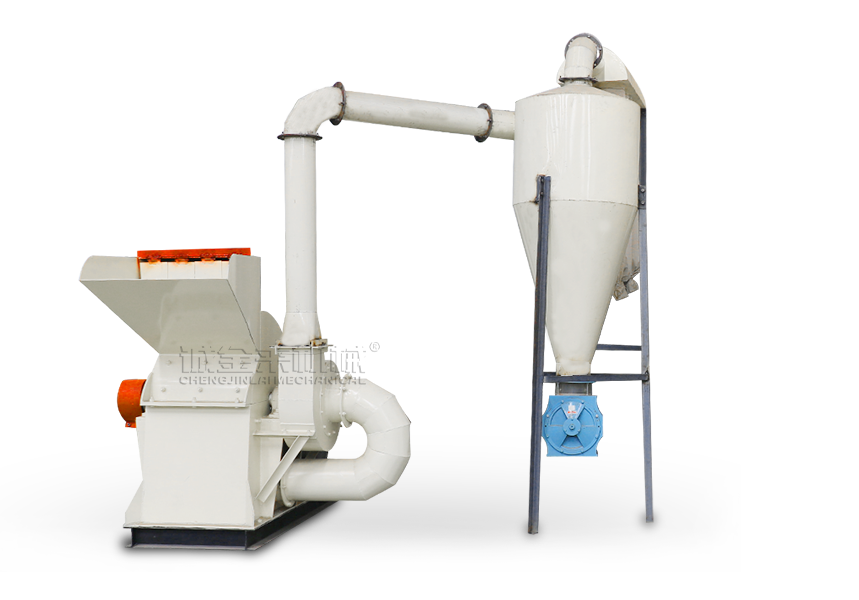

B.Double mouth crusher is a fine crushing equipment that can process all kinds of wood, restos de madera, sucursales, sucursales, chips de madera, adorno, ladrar, bambú, corteza de bambú y otras materias primas en aserrín a la vez.

C.Rotary drum dryer is one of the traditional drying equipment, que es confiable en la operación, Flexible en funcionamiento, fuerte en adaptabilidad, y grande en capacidad de procesamiento. El diámetro y la longitud del equipo se determinan de acuerdo con los requisitos de secado.

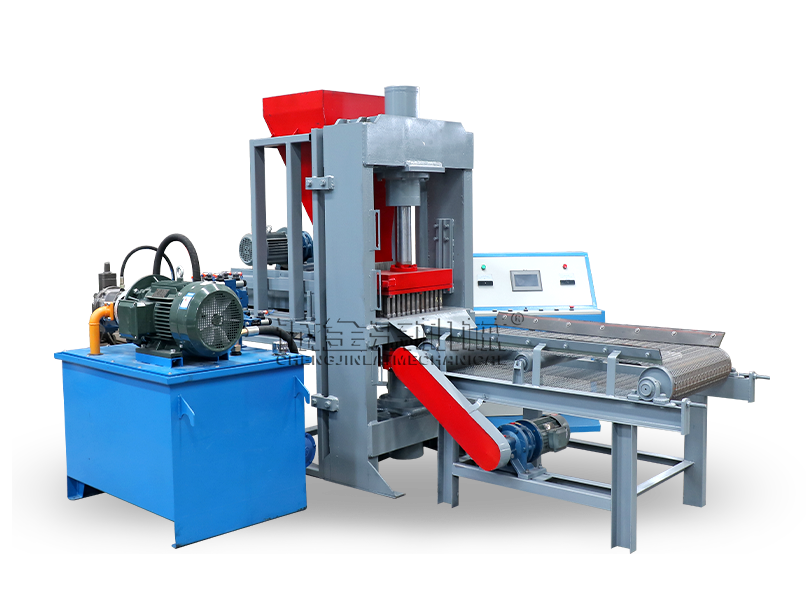

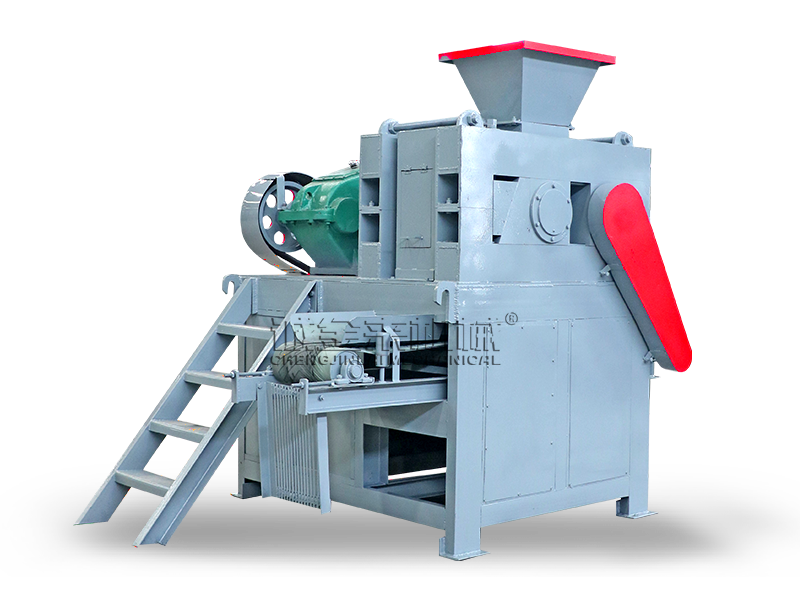

D.Wood charcoal briquette machine is a kind of forming equipment, que pasa principalmente a materiales de aserrín y madera o materiales de biomasa calificados (menos de 5 mm de tamaño, 12% humedad) a través de espirales, cilindros de formación de alta presión y anillos de calefacción. The machine-made rod is formed under high temperature and high pressure.

E.Hoisting carbonization furnace is an environmentally friendly and smokeless carbonization equipment. It can not only carbonize machine-made rods, but also directly carbonize raw materials such as logs, bloques de madera, cáscara de coco, and tree bark.

Can provide free production line design

When you plan to configure a carbonization production line, Háganos saber sus datos.

Estos materiales incluyen:

Tipo de materia prima, tamaño, humedad

Tamaño de la planta

Capacidad de transformador

Tipo y tamaño del producto terminado

Demanda de producción

Lo más detallado posible, el mejor, in order to customize your own carbonization production line equipment, y le proporcionaremos diagramas de planificación del sitio 3D de forma gratuita.

Productos relacionados

Veloz

Veloz

+8613838093177

+8613838093177