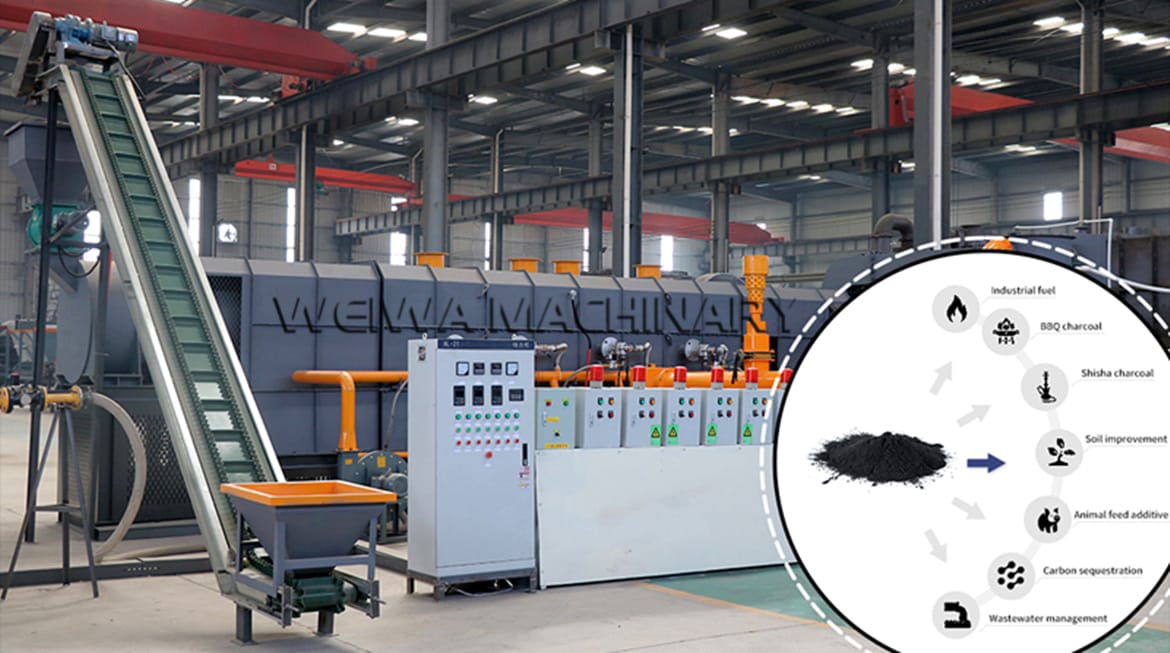

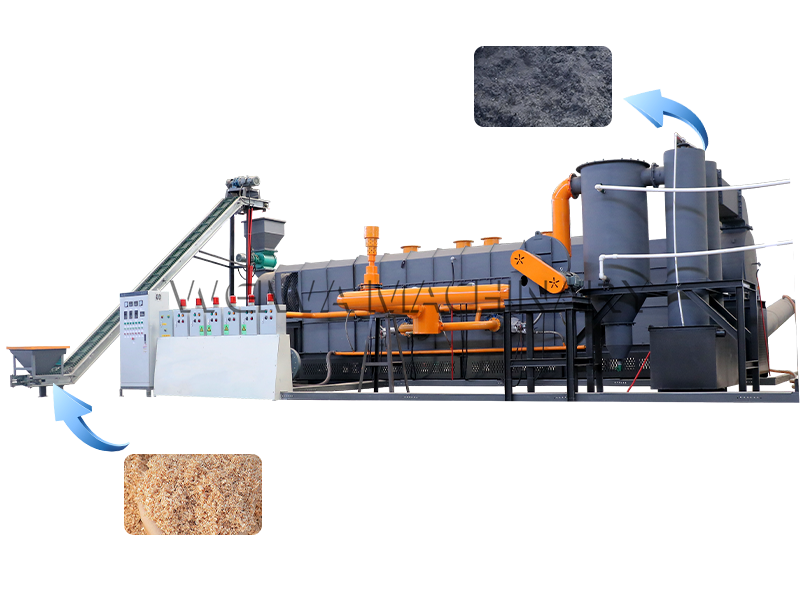

Sawdust Charcoal Making Machine – Turn Waste into Profitable Biochar!

Transform sawdust into high-value charcoal with our advanced continuous carbonization furnace.

- High Efficiency – Continuous operation, 24/7 production

- Eco-Friendly – Zero smoke, meets emission standards

- Multi-Purpose Biochar – Fuel, soil amendment, activated carbon & more

- Low Operating Cost – Automatic control, diseño de ahorro de energía

Why Sawdust Is Suitable for Making Charcoal?

Sawdust is the foam-like particles generated through woodworking operations in sawmills, pulp mills, etc.. While sawdust is typically seen as industrial waste in the timber sector, some of its characteristics make it ideal for the production of valuable charcoal.

High Carbon Content

Sawdust is primarily composed of carbon, which is a key component for charcoal production. This presents the potential for converting sawdust into charcoal.

Estructura porosa

The porous nature of sawdust provides numerous channels for the release of volatile organic compounds during the pyrolysis process. This helps in achieving a more efficient conversion of sawdust into charcoal.

Availability

Sawdust is a byproduct of various wood processing industries, making it readily available and cost-effective. This makes it a sustainable and economical choice for charcoal production.

Proven Capability to Produce High-quality Biochar

Biochar can be used for soil improvement, water treatment or industrial adsorbents, and the market demand is stable.

Testing Report of Sawdust Charcoal

Here we select local Chinese sawdust to test the quality of sawdust charcoal. The report indicates that the calorific value of the sawdust charcoal produced by our sawdust charcoal machine hasexceeded 6000 kcal/kg, approximately doubling that of raw sawdust (typically 3000-4500 kcal/kg). This outstanding performance makes sawdust charcoal a reliable and efficient energy source with good economic benefits. Por lo tanto, we sincerely recommend that you consider this project.

| No. | 1# |

| Amable | Saw dust |

| % de humedad total en toneladas | 6.84 |

| % de locura de agua analítica | 4.51 |

| % de contenido de cenizas en base seca | 5.871 |

| Materia volátil en base seca Vd% | 20.8 |

| % Fcad de carbono fijo | 68.91 |

| Contenido de azufre en base seca% St.d | 0.08 |

| Características de coquización 1-8CRC | |

| Nuevo calorímetro nacional de calorímetro seco de alto valor calórico Kcal/kg | 6454 |

| El nuevo método nacional de calorímetro estándar recibe el valor base bajo en calorías kcal/kg | 6088 |

Nota: Different types, humedad, sizes of raw materials, and technical parameters will have an impact on the biomass carbonization results.

Sawdust Charcoal Making Process

The entire sawdust recycling process mainly includes crushing, el secado, alimentación, carbonización, descarga, recuperación de gas combustible, tratamiento de gases de escape, and sawdust briquette production.

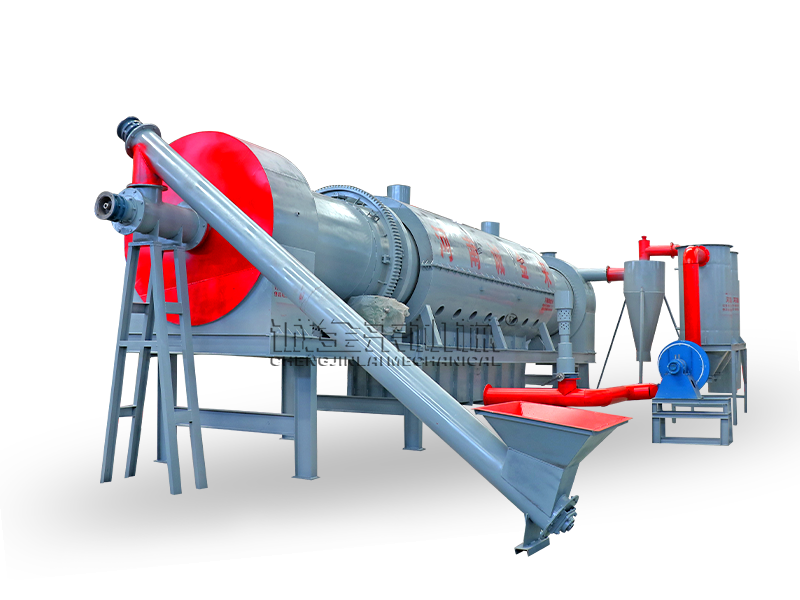

01 Preprocesamiento

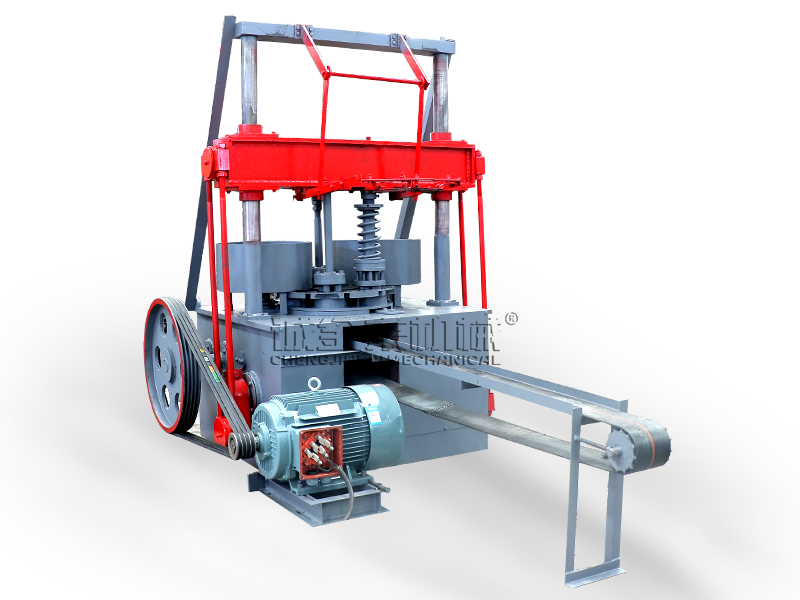

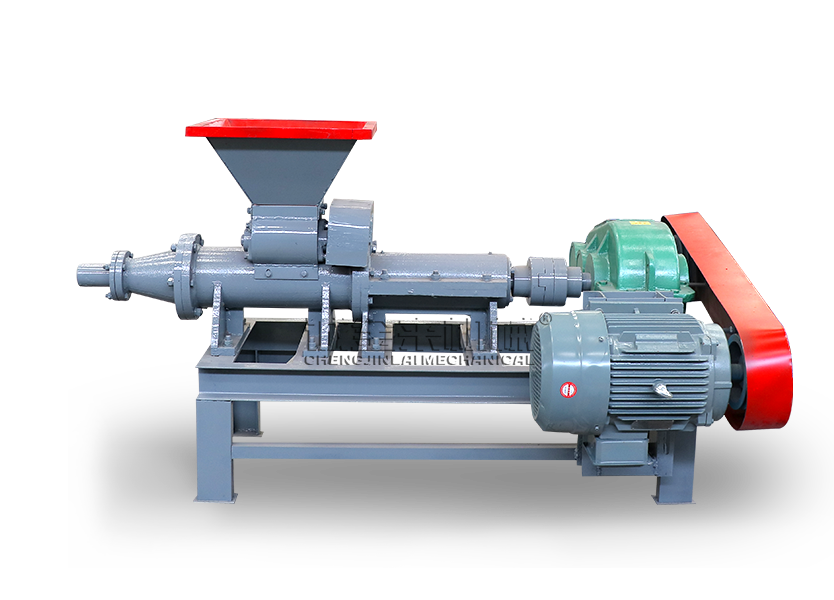

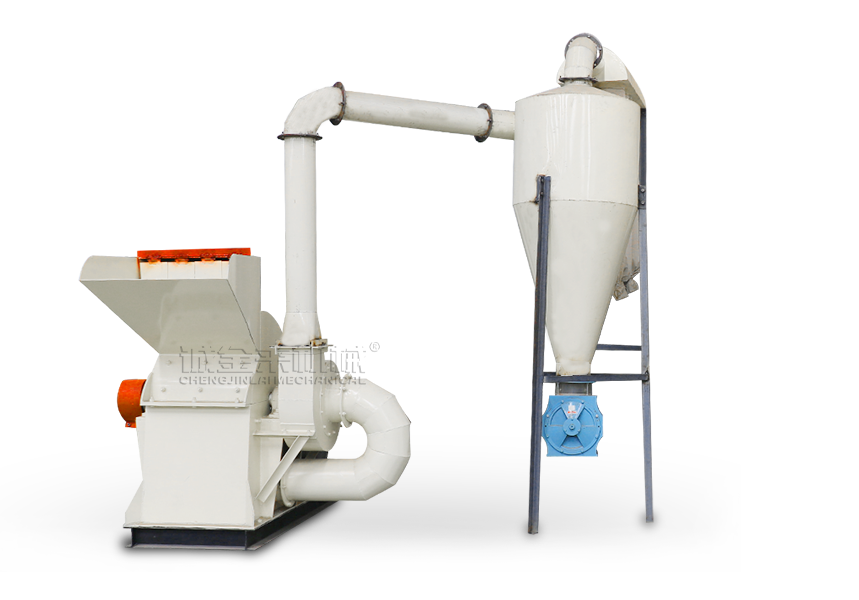

- Aplastante (opcional): The crushing system processes sawdust into target sizes (Menos de 20 mm).

- El secado (opcional): The drying system processes the sawdust to a moisture content of less than 15%.

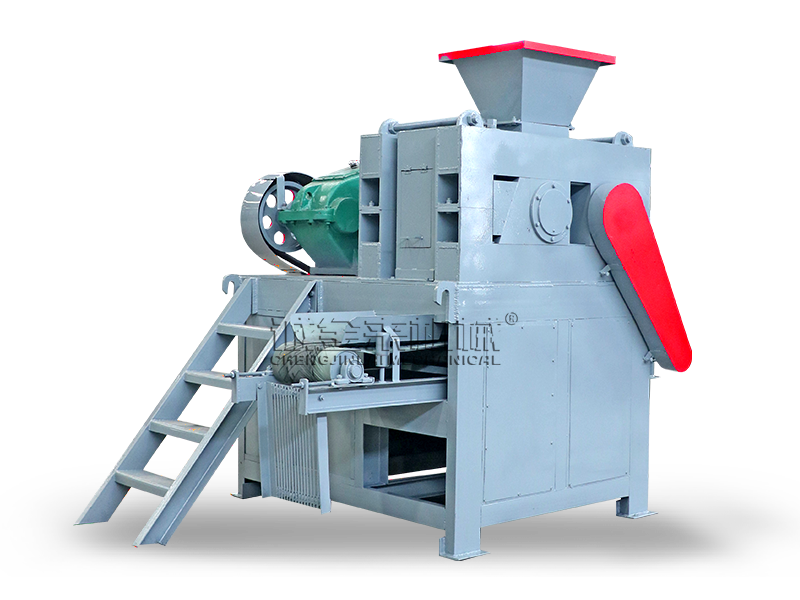

02 Carbonización

- Alimentación: The sawdust is automatically fed into the furnace via a conveyor belt, alimentador de tornillo o correa z.

- Carbonización: Después de calentar el horno principal, La temperatura aumenta gradualmente. The initial temperature helps dry out some of the moisture in the sawdust. Cuando la temperatura alcanza 250 grados Celsius, Comienza la desmetilación. El gas combustible comienza a generar. En 280 grados Celsius, Comienza la reacción exotérmica. Las moléculas de hidrocarburos se dividen en moléculas de carbono más pequeñas e hidrógeno. El carbón comienza a producirse. A medida que alcanza la temperatura 450 grados Celsius, Los compuestos de anillo aromático comienzan a reaccionar.

03 Descarga

- Sawdust charcoal: A través de un descargador de refrigeración por agua de tres etapas, sawdust charcoal below 45 Grados Celsius se recolectan.

- Alquitrán & colección de vinagre de madera (opcional): A través del condensador, alquitrán (aceite de biomasa) y el vinagre de madera se separa y se recogen por separado.

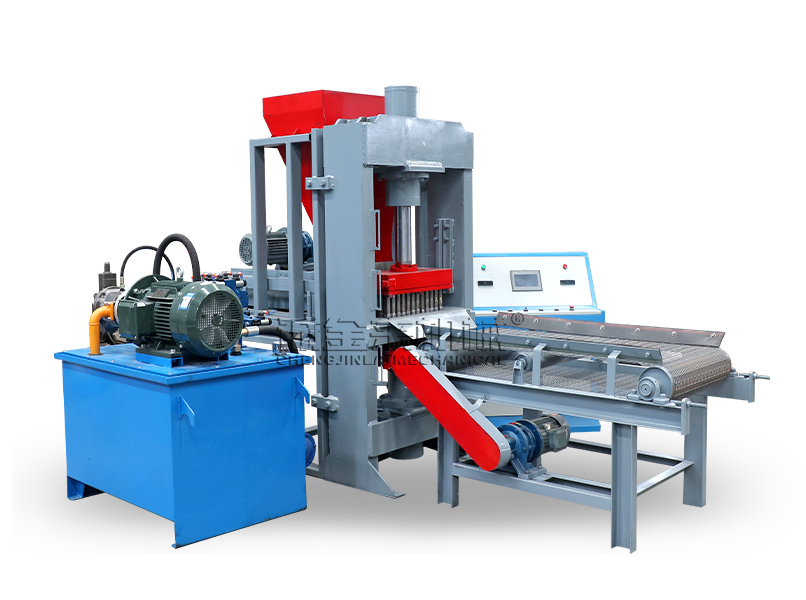

- Sawdust charcoal briquette making (opcional): After being processed by the sawdust charcoal briquette machine, La forma original del carbón se puede hacer en la forma requerida, como Round Round, cuadrado, palo, etc..

04 Recuperación de gas combustible

- Después de la condensación y el tratamiento de la eliminación de azufre, El gas combustible se puede recuperar y reutilizar.

- También podemos introducir el exceso de calor del horno de carbonización en la secadora para reciclar el gas combustible, ahorrando combustible para la secadora.

05 Tratamiento de gases de escape

- El gas de emisión es tratado por una torre de spray, Cortina de agua Torre de desamparo, y torre de enfriamiento. El gas de emisión procesado cumple con los estándares de emisión de la UE.

- Weiwa Group proporciona un sistema de tratamiento de gases de escape personalizado de alto nivel.

Features of Sawdust Charcoal Making Machine

Equipado con dispositivo de alarma

El gabinete eléctrico del PLC tiene un dispositivo de alarma, y habrá una pantalla de alarma y una alarma para algunas fallas eléctricas.

Con sello de agua a prueba de explosión

Hay un sello de agua a prueba de explosión en la tubería combustible (Para evitar la presión anormal de gas combustible en el equipo)

Guía de ventilador de frecuencia variable

La dirección del gas en todas las tuberías es dirigida por el ventilador (El ventilador es frecuencia variable), y se mostrará en el PLC cuando la tubería esté bloqueada

Alta eficiencia de calor

El material no está en contacto con el gas de combustión y no está contaminado por aire caliente.

Buen efecto de ahorro de energía

La tasa de utilización de calor de este equipo es mayor, El uso del cambio de calor por aire puede mejorar efectivamente la eficiencia térmica mediante 5-10%, y el efecto de ahorro de energía es bueno.

How to use Sawdust Charcoal Making Machine to make profits

Sawdust to charcoal is a circular economy solution. Sawdust are converted into biomass charcoal resources. Biomass charcoal can be applied to both the cultivation industry and the food processing industry. Esto permite un desarrollo sostenible y una solución verdaderamente de circuito cerrado..

Acceso garantizado al comercio de crédito de carbono

- High carbon content

- 100% Natural and environmentally friendly

- Trap large amounts of carbon dioxide and Improve carbon footprint

- Be used for market transactions, such as carbon credits, carbon offsets

Soil Amendment

- 80% Estructura microporosa para mejorar la aireación y drenaje del suelo

- Proporcionar algunos elementos traza, como el potasio, magnesio, zinc

- La alcalinidad y el intercambio iónico ayudan a ajustar el pH del suelo y ahorrar en los costos de fertilizantes

High-Quality Sawdust Biochar Output

The sawdust charcoal not only finds renewed application in the wood processing industry as a fuel but also has extensive uses in various other industries.

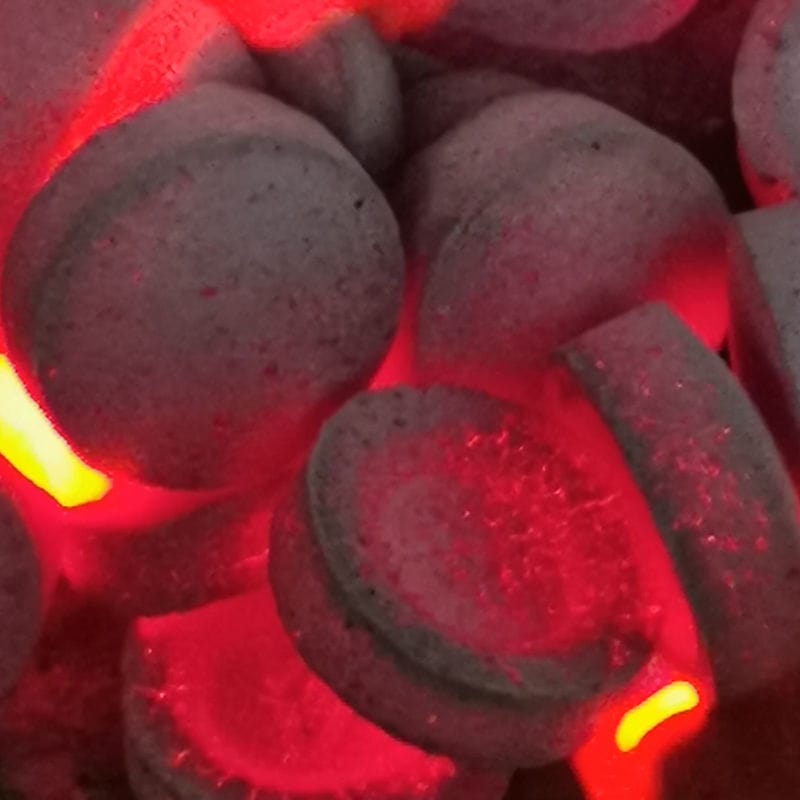

Carbón de cachimba

Sawdust charcoal, after undergoing special treatment, can be used as a flavorful hookah charcoal. It is employed in hookah pipes for people to enjoy, helping to relax the mind and body.

BBQ Charcoal and Cooking

Sawdust charcoal is easy to light. It is ideal for home cooking and BBQ. You can purchase charcoal briquette machine at Weiwa Group.

Solicitud de subvención de póliza

Algunos países o regiones otorgan subsidios o incentivos fiscales para el uso de energía de biomasa., como el de la UE “Nuevo acuerdo ecológico” o la política de apoyo a las energías renovables de China.

Sawdust biochar is characterized by good stability and slow decomposition. Mixing it into the soil helps with carbon sequestration, reducing the concentration of carbon dioxide in the atmosphere.

Productos relacionados

Veloz

Veloz

+8613838093177

+8613838093177