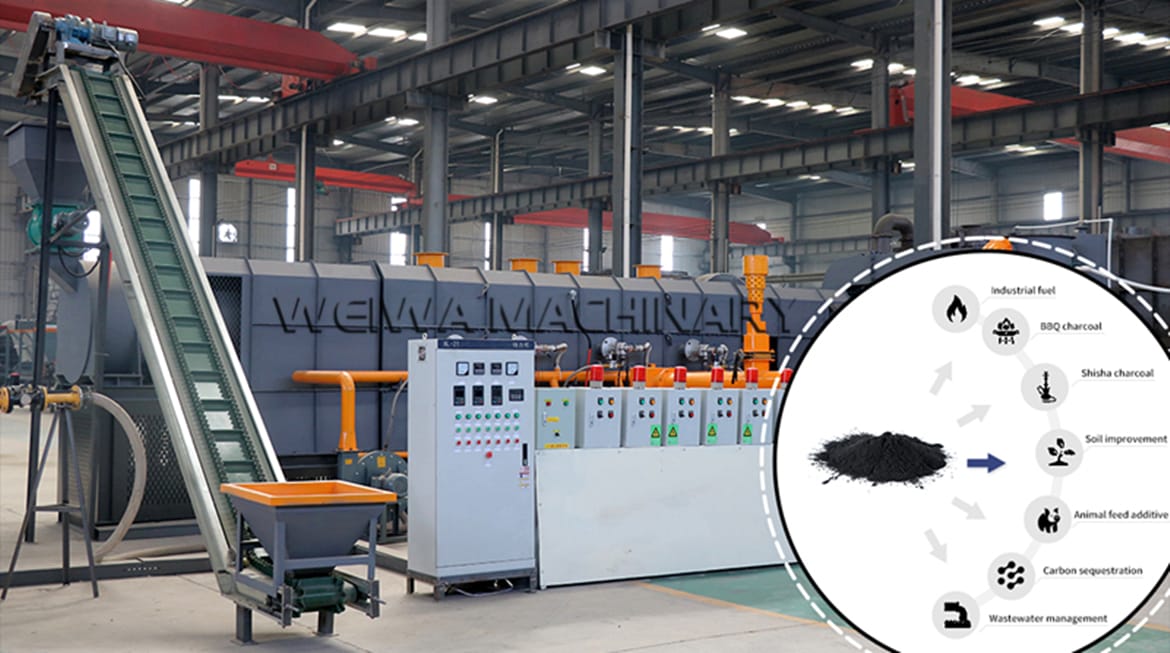

¿Está buscando una máquina de fabricación de carbón de husaje de arroz a la venta?? Por favor, eche un vistazo al grupo Weiwa! Podemos proporcionarle la solución y la máquina más adecuados para usted.. Ven y síganos para aprender sobre la máquina aquí.

¿Qué es la máquina de fabricación de carbón de la cáscara de arroz??

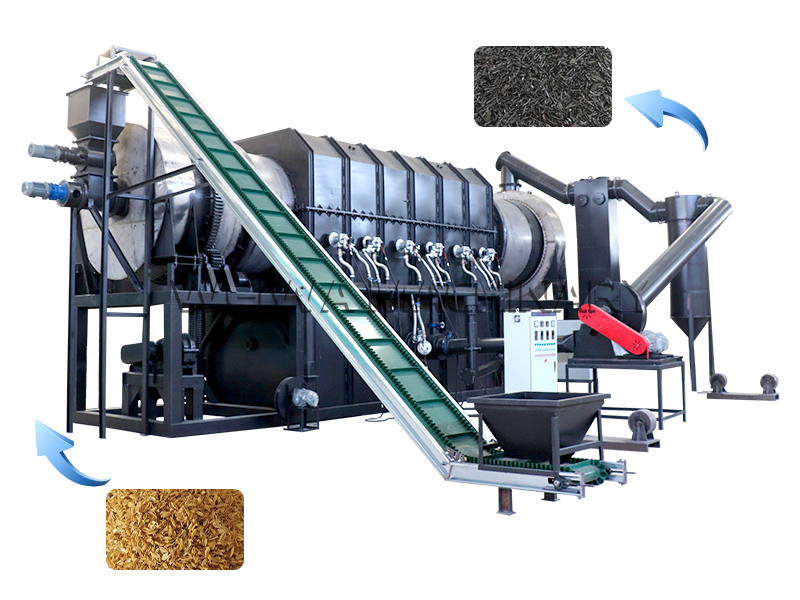

Una máquina de fabricación de carbón de la cáscara de arroz transforma los desechos agrícolas (cáscara de arroz) en biochar a través de la carbonización a alta temperatura. Este proceso ecológico reduce los desechos y crea energía renovable. Con millones de toneladas de cáscara de arroz descartada anualmente, Métodos de eliminación tradicionales como la quema o los vertederos dañan el medio ambiente. Rice Husk Charcoal Making Machines ofrecen una solución sostenible al convertir los desechos en productos valiosos.

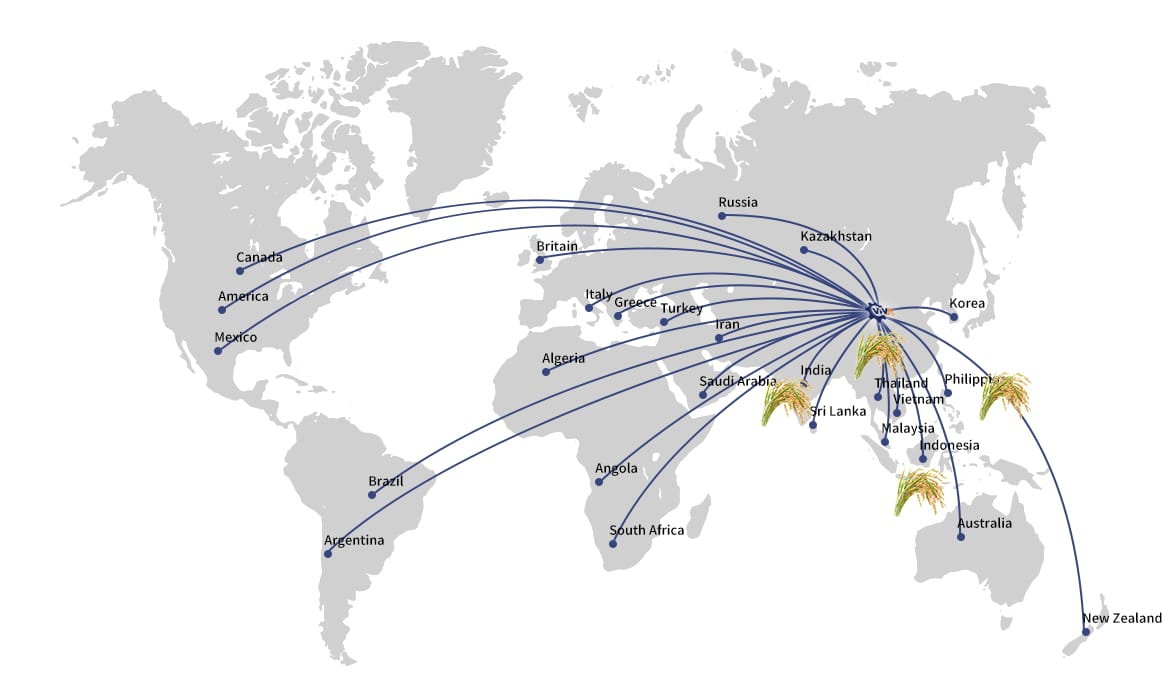

Antecedentes de la industria de producción de arroz

Estos son los principales países del mundo para la producción de arroz por acre en 2024:

Eliminación de la cáscara de arroz Desafíos actuales

Baja tasa de reciclaje

Aproximadamente 150 Se generan millones de toneladas de cáscara de arroz en todo el mundo cada año. Sin embargo, La tasa de reciclaje de la cáscara de arroz es menor que 25%. La falta de un sistema de reciclaje e infraestructura efectivos es la razón principal. Como resultado, La cáscara de arroz a menudo se abandona o no se utiliza por completo.

Tecnología inmadura

Actualmente, Las tecnologías de procesamiento de cáscara de arroz disponibles son ineficientes. Por ejemplo, La incineración para la energía o el compostaje simple no puede tocar completamente el valor potencial de la cáscara de arroz. Tecnologías de procesamiento más avanzadas, como la biomasa de carbonización, aún no se han utilizado ampliamente.

Problemas de viabilidad económica

El reciclaje a gran escala de la cáscara de arroz a menudo implica altos costos de terceros. Incluyen colección, Tarifas de transporte y procesamiento. Estos costos pueden ser demasiado altos para los productores de arroz y las plantas de procesamiento.. Como resultado, Las razones de viabilidad económica provocan que los profesionales reciclaran.

Solución sostenible: Máquina de fabricación de carbón de la cáscara de arroz

-1.jpg)

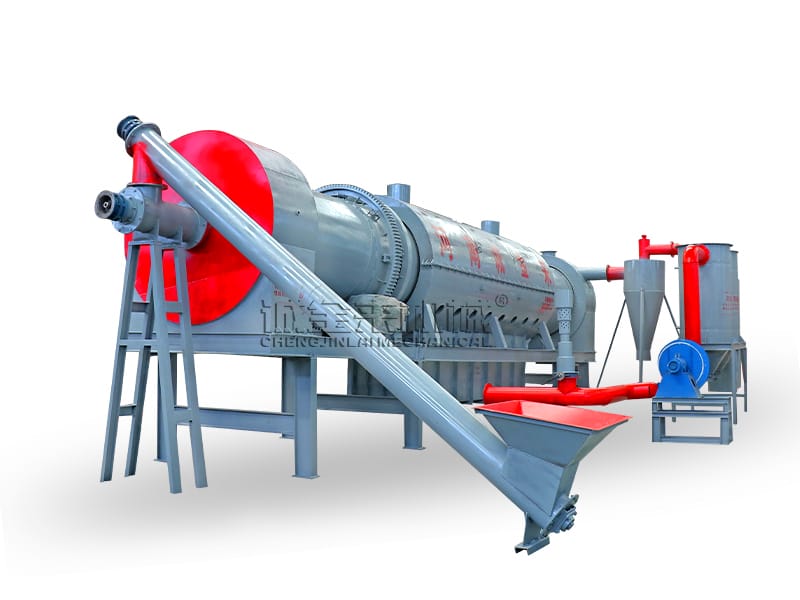

Cáscara de arroz máquina de fabricación de carbón es la solución actual de reciclaje de residuos agrícolas actuales. Es favorecido por los recicladores por su amabilidad ambiental y alta eficiencia.. La máquina logra la reducción y la utilización de recursos de la cáscara de arroz.

Mediante el uso de la máquina de fabricación de carbón de la cáscara de arroz, Podemos obtener el producto final más importante, carbón de la cáscara de arroz. El carbón se puede procesar más en la cachimba industrial o el carbón de barbacoa, ambos tienen valores altos y se pueden aplicar en muchas áreas. Es la máquina más adecuada para la producción de carbón o la producción de carbón de barbacoa.

carbonero

Carbón de barbacoa

Cómo usar la máquina de fabricación de carbón de la cáscara de arroz?

Características de la máquina de fabricación de carbón de la cáscara de arroz

Equipado con dispositivo de alarma

El gabinete eléctrico del PLC tiene un dispositivo de alarma, y habrá una pantalla de alarma y una alarma para algunas fallas eléctricas.

Con sello de agua a prueba de explosión

Hay un sello de agua a prueba de explosión en la tubería combustible (Para evitar la presión anormal de gas combustible en el equipo)

Guía de ventilador de frecuencia variable

La dirección del gas en todas las tuberías es dirigida por el ventilador (El ventilador es frecuencia variable), y se mostrará en el PLC cuando la tubería esté bloqueada.

Alta eficiencia de calor

El material no está en contacto con el gas de combustión y no está contaminado por aire caliente.

Buen efecto de ahorro de energía

La tasa de utilización de calor de este equipo es mayor, El uso del cambio de calor por aire puede mejorar efectivamente la eficiencia térmica mediante 5-10%, y el efecto de ahorro de energía es bueno.

Obtenga beneficios de la máquina de carbón de la cáscara de arroz

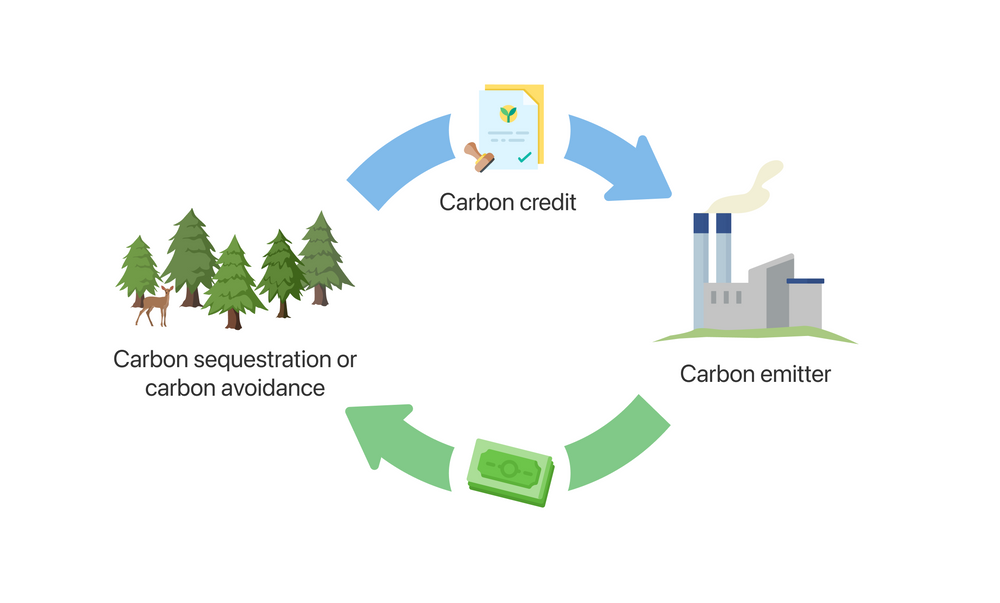

Acceso garantizado al comercio de crédito de carbono

El biochar producido después de que la cáscara de arroz se trata mediante un horno de carbonización continuo tiene una estructura de carbono estable y se puede almacenar en el suelo durante cientos de años, Reducir el dióxido de carbono en la atmósfera. Este proceso está en línea con la categoría de "eliminación de carbono" o "secuestro de carbono" en el proyecto de crédito de carbono, y se puede solicitar créditos de carbono A través de certificaciones internacionales (como VCS, Gs, etc.)

Salida de carbón de cáscara de arroz de alta calidad

Nuestro proceso de carbonización utiliza carbonización a alta temperatura, Garantizar la producción de Biochar que cumple con los estándares EBC. La relación molar H/C del producto, contenido de metal pesado, y los niveles de HAP se alinean con los requisitos para una variedad de escenarios de aplicación EBC, Garantizar la calidad superior de biochar para diversos usos.

Mejora del suelo

- 80% Estructura microporosa para mejorar la aireación y drenaje del suelo

- Proporcionar algunos elementos traza, como el potasio, magnesio, zinc

- La alcalinidad y el intercambio iónico ayudan a ajustar el pH del suelo y ahorrar en los costos de fertilizantes

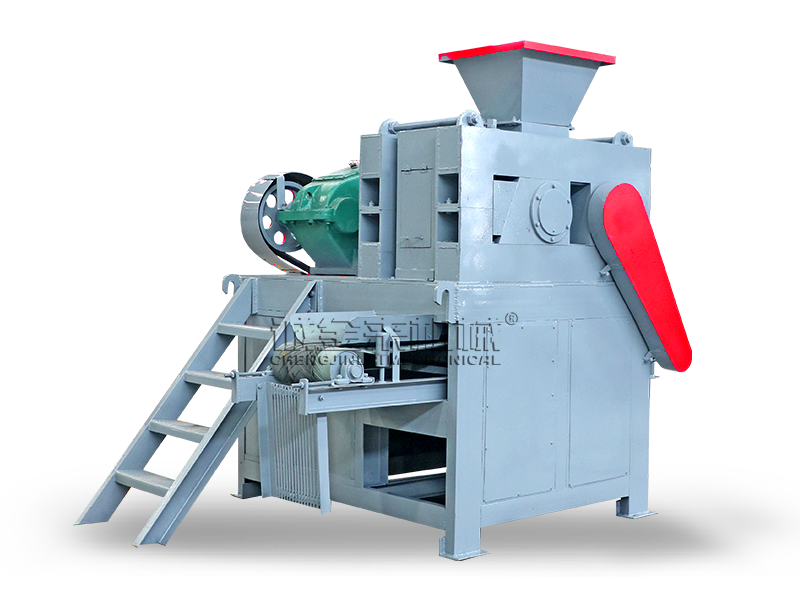

Productos relacionados

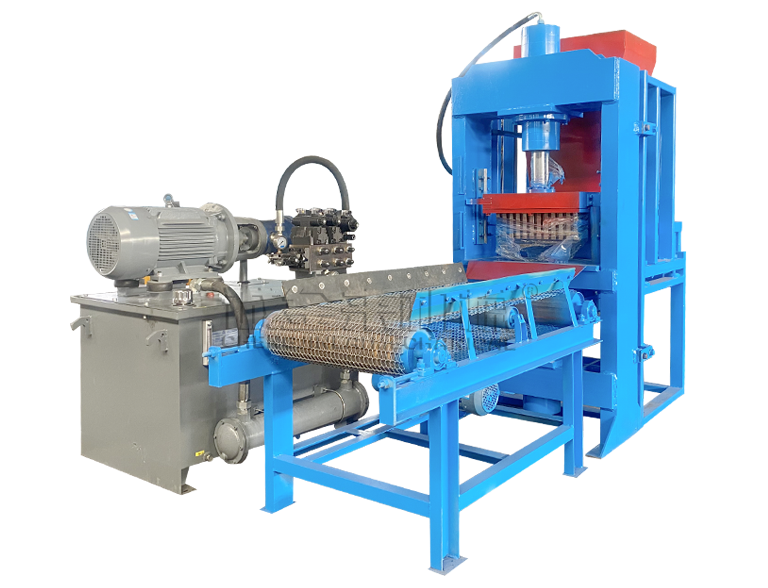

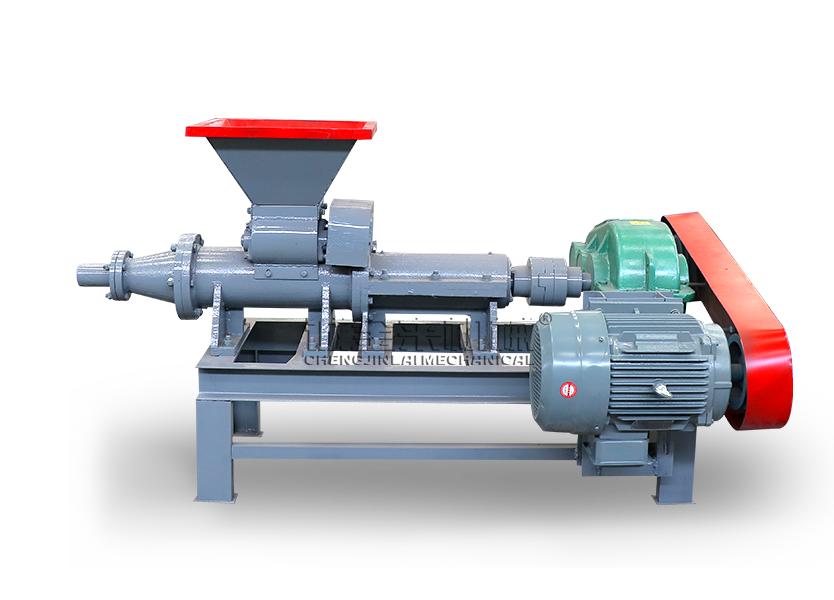

Diferentes tipos de equipos de carbonización

Mejor efecto de carbonización, mayor tasa de carbonización 304 Material inoxidable para el horno interior. Alta resistencia a la temperatura.

Contenido de carbono fijo más alto.

Adecuado para materiales grandes como troncos de madera.

Estructura simple,fácil de operar y mantener controlable y ajustable

temperatura de carbonización

Veloz

Veloz

+8613838093177

+8613838093177