Ball mill introduction

Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including silicate, new-type building material, material refractario, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, Gold Ore, Marble, Feldspar, Quartz, Calcite, Limestone, Copper Ore, Iron Ore etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grid type and overflow type due to different ways of discharging material.

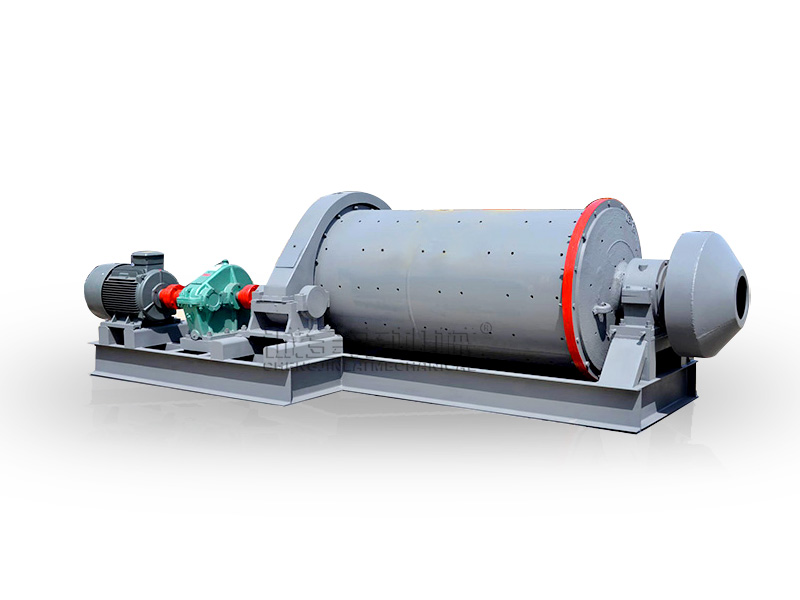

The ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control), etc.. The hollow shaft is made of cast steel, the lining can be disassembled and replaced, the rotary gear is processed by casting hobbing, and the cylinder body is inlaid with wear-resistant lining plate, which has good wear resistance.

Principio de trabajo

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Raw Materials and Final Products

Continuous ball mill is widely used in powder-making production line including cement, silicate, new-type building material, material refractario, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc., with medium hardness.

Features of Ball Mill

1. Using advanced process design, the cylinder is tightly sealed to ensure dust overflow during operation.

2. The cylinder is cast with high-quality steel to extend the service life.

3. The good effect of saving energy, strong durability, low cost of grinding

4. The machine output can be increased by 15-20% compared with the general cement mill. the power consumption is reduced by about 10%

Customer site

We sincerely welcome every valued client from home and abroad to visit our company and enter into long term business relationship with every friend.

Embalaje & Delivery

Comenzando su negocio aquí!

Hasta ahora, Tenemos clientes más de 130 países, Indonesia, India, Malasia, Laos, Myanmar, Tailandia,Vietnam,Filipinas,Pakistán, Sri Lanka, Líbano, Georgia, Pavo, Polonia, checo, Mongolia, Corea del Sur, Rumania, Egipto, Sudán,Túnez,Argelia, Etiopía, Guinea ecuatorial de Tanzania, Zambia, México, Sudáfrica, etc..

De nada si desea visitar nuestra fábrica! Puedes contactarnos ahora!

Veloz

Veloz

+8613838093177

+8613838093177