Introducción a las briquetas de carbón de cáscara de coco

En los últimos años, La demanda de alternativas de combustible sostenibles y ecológicas ha aumentado, creaciónBriquetas de carbón de cáscara de cocoUn producto muy solicitado. Derivado decáscara de coco, Estas briquetas no solo son una excelente fuente de energía renovable, sino también una oportunidad de negocio rentable. AMaquinaria de Weiwa, Nos especializamos en proporcionar eficientesBriqueta de carbón de cáscara de coco que fabrican líneas de producciónQue transforman las cáscaras de coco residuales en briquetas de carbón de alta calidad con un impacto ambiental mínimo.

Por qué elegir concha de coco para la producción de carbón?

Las cáscaras de coco sonrico, material de biomasa densa en carbonoEso es una excelente materia prima para la producción de carbón. A diferencia del carbón de madera tradicional, El carbón de carbón de cáscara de coco ofrece varias ventajas:

- Alto contenido de carbono fijo: Asegura un tiempo de quemadura más largo y una mayor producción de energía.

- Ceniza baja & Emisión de humo: Lo hace más limpio y más amigable para el medio ambiente.

- Durable & Estructura densa: Ideal para briqueting sin agentes de unión excesivos.

- Utilización de desechos: Convierte los desechos agrícolas en una mercancía valiosa.

Dados estos beneficios, Briquetas de carbón de cáscara de cocoSon ampliamente utilizados enBarbacoas, Twys pero smdítico, calefacción industrial, e incluso como carbono activado.

Briqueta de carbón de caparazón de coco que fabrica línea de producción

ElLínea de producción de briquetas de carbón de capuleta de cocoInvolucra varias etapas clave, cada uno crucial para producir briquetas de alta calidad de manera eficiente. A continuación se muestra un desglose detallado delflujo de trabajo completo:

1. Colección de materia prima & Pretratamiento

El proceso comienza conrecolectando cáscaras de coco secas, preferiblemente aquellos que se han secado o se secaron mecánicamente para reducir el contenido de humedad (idealmente debajo15%). El secado adecuado garantiza una mejor eficiencia de carbonización y reduce el consumo de energía en etapas posteriores..

- Aplastante (Opcional): Si las conchas son demasiado grandes, untrituradora o molino de martilloPuede usarse para dividirlos en piezas más pequeñas para una carbonización uniforme.

2. Carbonización - convertir los conchas en carbón

Elproceso de carbonizaciónEs el corazón de la producción de carbón, donde las cáscaras de coco se calientan en un ambiente sin oxígeno para descomponer la materia orgánica en carbón.

En el video, Las cáscaras de arroz se usan como ejemplo

Principio de trabajo de carbonización:

En el siguiente video, Tomamos las cáscaras de arroz como ejemplo

- Las cáscaras de coco se alimentan en unhorno de carbonización (horno rotativo, horno de ladrillos, o carbonizador continuo).

- El horno se calienta a300–600 ° CEn una cámara privada de oxígeno (Para evitar la combustión).

- Por encima de4–8 horas, las conchas se sometenpirólisis, liberar gases volátiles y dejar atráscarbón sólido.

AMaquinaria de Weiwa, OfrecemosEquipo de carbonización avanzadoQue maximiza el rendimiento mientras minimiza las emisiones.

3. Aplastante & Moliendo el carbón

El resultantecarbón de cáscara de cocoEs quebradizo y necesita ser aplastado en polvo fino (por lo general3–5 mm o más fino) por briquetting.

- Untrituradora de carbón o molino de martilloSe usa para descomponer el carbón en un tamaño consistente.

- El tamaño de partícula adecuado aseguramejor vinculación y formación de briquetas uniformes.

4. Mezclar con carpeta (Opcional)

Mientras que algunos procesos se usanBriquetting sin carpeta, Muchos fabricantes agregan uncarpeta natural (P.EJ., almidón, melaza, o arcilla)Para mejorar la cohesión.

- La carpeta se mezcla con el polvo de carbón en unmezcla de tamborPara garantizar una distribución uniforme.

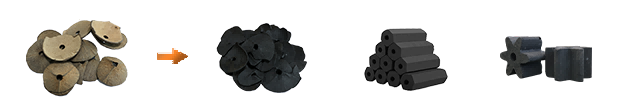

5. Briquetting - formando las briquetas

Elproceso de briquetingComprime el polvo de carbón enuniforme, briquetas densasUsando alta presión.

Cómo funciona Briquetting:

- Elmezcla de binder de carbónSe alimenta a unBriqueta (generalmente una prensa de tornillo o prensa hidráulica).

- Bajopresión alta (50–100 MPA), la mezcla se moldea encilíndrico, cuadrado, u briquetas ovales.

- No se necesita pegamento adicional si el carbón tiene suficientes propiedades de unión natural.

AMaquinaria de Weiwa, nuestromáquinas de briqueta de cáscara de cocoEstán diseñados paraalta eficiencia, bajo consumo de energía, y rendimiento duradero.

6. Secando las briquetas

Las briquetas recién presionadas contienenhumedad alta (10–20%)Y debe ser secado aAsegurar la dureza y la larga vida útil.

- Secado por el sol: Lento pero rentable (Toma 2 a 3 días).

- Secado mecánico (Secador de aire caliente): Más rápido (6–12 horas) y más controlado, asegurandoNiveles de humedad consistentes por debajo del 8%.

7. Embalaje & Almacenamiento

Una vez secado, las briquetas son:

- EnfriadoA la temperatura ambiente.

- EmpaquetadoEn bolsas o capturas para almacenamiento y distribución.

- Almacenado en un lugar secoPara evitar la absorción de humedad.

Principios de trabajo de la línea de producción de briquetas de carbón de coco de coco

El conjuntoLa línea de producción funciona con un flujo sistemático, asegurandoeficiencia, calidad, y desperdicio mínimo.

Principios clave:

- Descomposición térmica (Carbonización): Convierte la biomasa en carbón a través de la pirólisis controlada.

- Compresión mecánica (Briqueting): Utiliza alta presión para formar briquetas densas sin aglutinantes (o con aglutinantes mínimos).

- Control de humedad (El secado): Asegura que las briquetas sean difíciles, durable, y duradero.

NuestroEquipo de maquinaria de WeiwaEstá diseñado paraoptimizar cada etapa, reducir el desperdicio de energía y maximizar la producción.

Potencial de mercado & Oportunidades de negocio

ElDemanda global de briquetas de carbón de cáscara de cocoEstá creciendo rápidamente debido a:

1. Alternativa de combustible ecológica

- Utilizado enhogar, restaurantes, e industriasComoalternativa más limpia a la madera o al carbón.

- Preferido porTwys pero smdítico, shisha, y barbacoasDebido a suaroma y quemadura limpia.

2. Industria del carbono activado

- Carbón de cáscara de coco es unMateria prima principal para el carbono activado, utilizado enfiltración de agua, purificación de aire, y aplicaciones médicas.

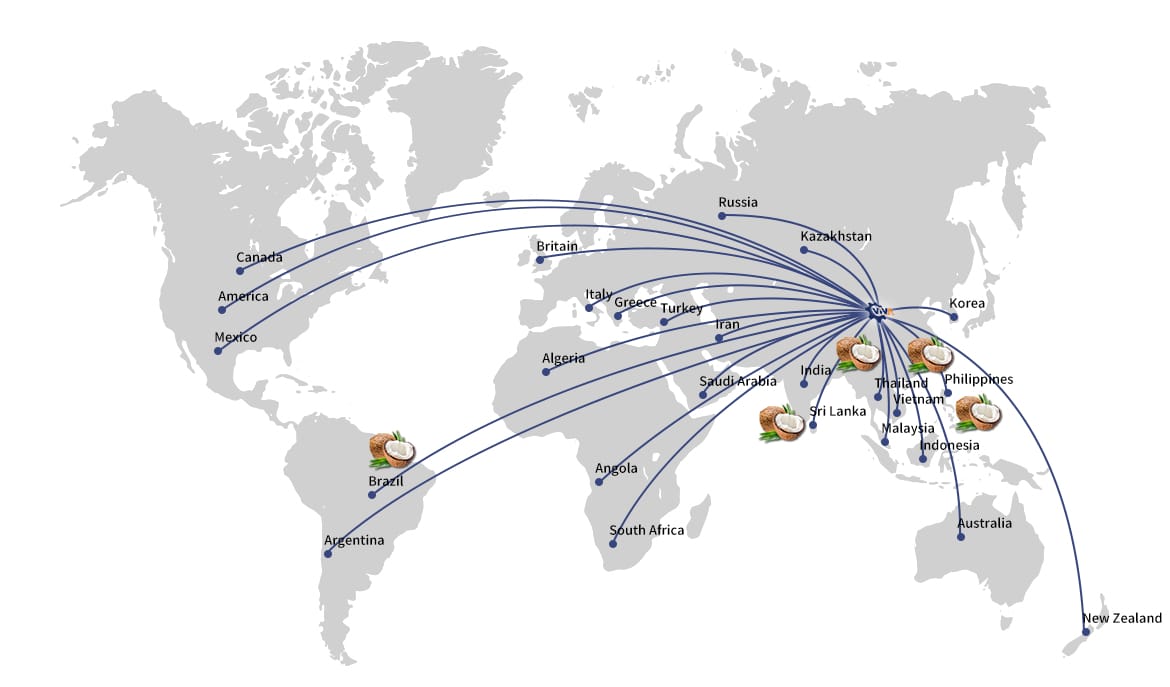

3. Potencial de exportación

- Países comoJapón, Corea, Europa, y el Medio OrienteImportar briquetas de cáscara de coco de alta calidad a granel.

4. Apoyo gubernamental & Tendencias de sostenibilidad

- Muchos gobiernos promuevenProyectos de energía de biomasa, ofrendasubsidios o incentivos fiscalesPara productores de carbón.

Invirtiendo en unBriqueta de carbón de caparazón de coco que fabrica línea de producción, Los empresarios pueden aprovechar unlucrativo, ecológico, y mercado de alta demanda.

Por qué elegir Weiwa Machinery para su línea de producción?

AMaquinaria de Weiwa, Somos unfabricante líder de equipos de procesamiento de biomasa, especializado enLíneas de producción de briquetas de carbón de capuleta de coco. He aquí por qué somos tu mejor opción:

✅Equipo de alta calidad- nuestrocarbonizadores, trituradores, Briqueta, y secadorasEstán construidos paradurabilidad y eficiencia.

✅Soluciones personalizables- DiseñamosLíneas de producción llave en manoAdministrado a su escala de producción.

✅Tecnología de eficiencia energética- Nuestras máquinas minimizanConsumo de energía y emisiones.

✅Experiencia global- Hemos suministrado equipo paraencima 50 países, asegurandoSoporte confiable y servicio postventa.

✅Fijación de precios competitivos- Obtenermaquinaria premium a precios directos de fábricaConOpciones de pago flexibles.

Comience su negocio de briqueta de carbón de caparazón de coco con maquinaria Weiwa

ElBriqueta de carbón de caparazón de coco que fabrica línea de producciónEs unrentable, sostenible, y negocios en demanda. Con el equipo y el proceso correctos, puedes convertirdesechos de coco de coco en briquetas de carbón de alto valorParamercados nacionales e internacionales.

Maquinaria de WeiwaBrindarcompleto, confiable, y soluciones de producción eficientesPara ayudarlo a tener éxito en esta industria. Si eres unemprendedor a pequeña escala o un gran fabricante, Tenemos elEquipo y experiencia correctosPara apoyar su empresa.

Contáctenos hoyPara conseguir unconsulta gratuita, cotización, o demostración de equipoPara tuLínea de producción de briquetas de carbón de capuleta de coco.

Acerca de Maquinaria de Weiwa

Maquinaria de WeiwaEs unFabricante profesional de equipos de procesamiento de biomasa, especializado enmáquinas de fabricación de carbón, Prensa de briqueta, hornos de carbonización, y sistemas de secado. Conaños de experiencia y una base global de clientes, Estamos comprometidos a proporcionarinnovador, eficiente, y soluciones rentablesPara la producción de energía sostenible.

Permítanos ayudarlo a convertir las conchas de coco en ganancias: parte con la maquinaria de Weiwa hoy!

Veloz

Veloz

+8613838093177

+8613838093177