La línea de producción de bloque de carbón de chips de madera industrial es un equipo avanzado que utiliza eficientemente los desechos de biomasa, como chips de madera,cáscara de arroz,cáscaras de maní,material de aserrín ect. y está diseñado para convertir los chips de madera en bloques de carbón de alto valor calórico para satisfacer la demanda del mercado de combustibles para el medio ambiente. A medida que el concepto de desarrollo sostenible se vuelve cada vez más popular, wood chip charcoal blocks are gradually gaining widespread attention due to their low pollution and high efficiency.

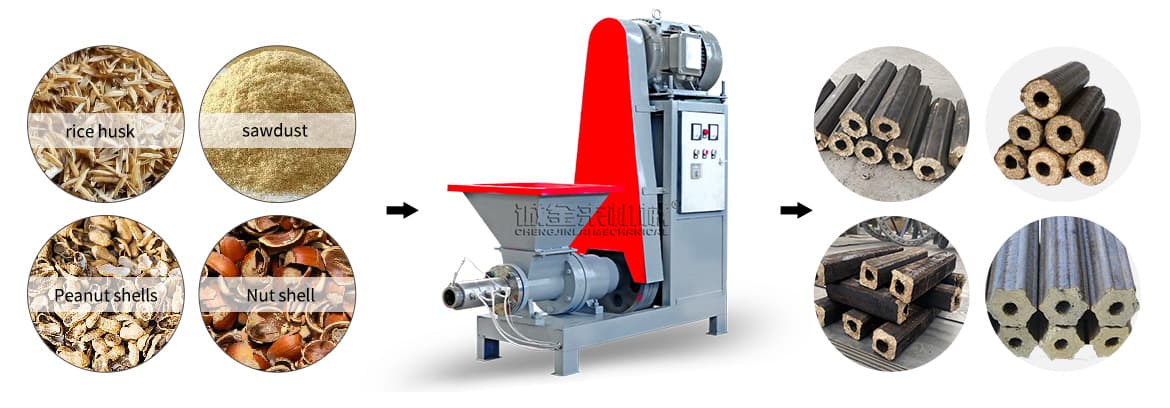

Charcoal Briquettes Making Machine Raw Materials & Productos finales

Charcoal briquette making machine has a wide range of raw materials,como troncos de madera, bambú, cáscara de coco, conchas de palma, chips de madera, cáscaras de arroz, cáscara de nueces, Conchas de nogal y varias materias primas de biomasa.

Raw material is graphite powder, coal powder or mineral powder, it can be crushed directly and added into the appropriate binderand stirred evenly before moulding and making rods.

(Tamaño:menos que 5 mm;Moisture content:menos que 25%)

Final products:

◆ Esta briqueta de biocombustible tiene 45-80 mm de diámetro, ocurre en el cilindro cuadrangular o hexagonal hueco o hexagonal hueco con un orificio de 15-20 mm a través del cuerpo.

◆ La forma disponible: cuadrado, hexagonal, pentágono, Pentágono con borde, Hexagon con borde.

◆ El diámetro disponible podría ser: 50mm,60mm,70mm,80mm y así sucesivamente

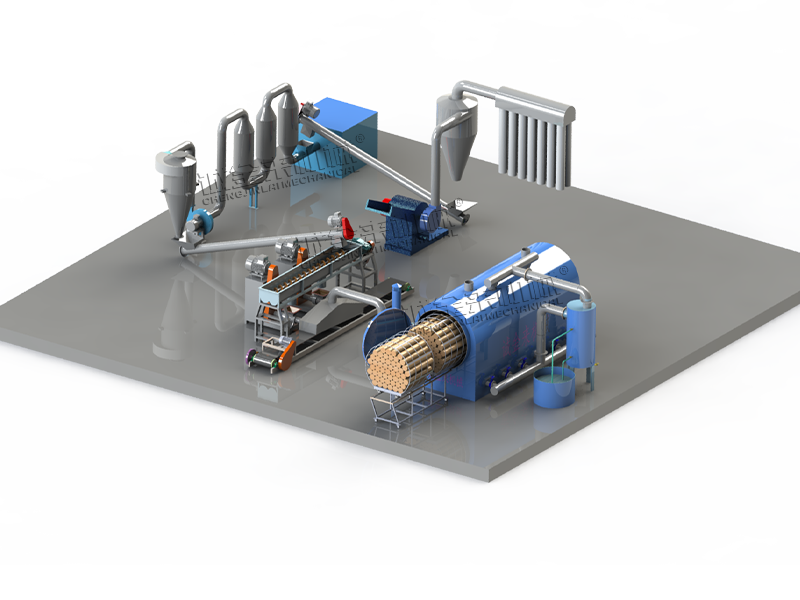

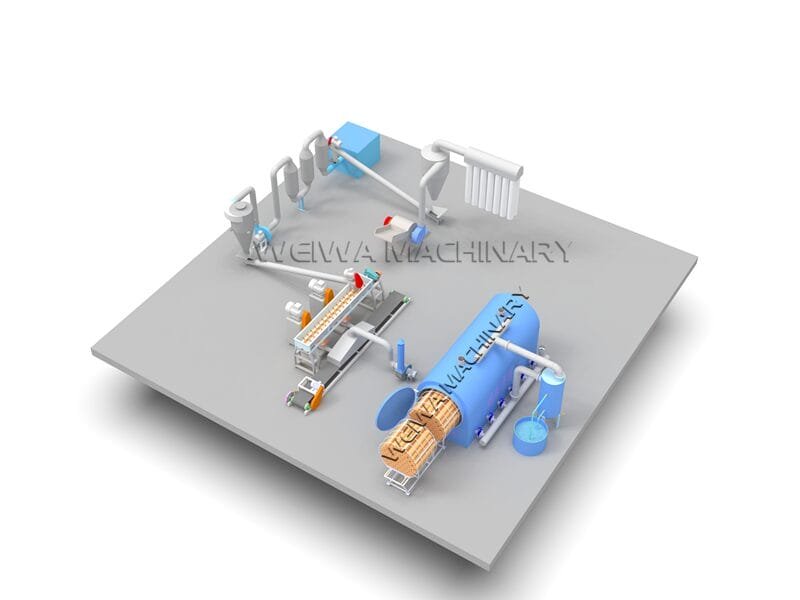

Wood Charcoal Briquette Production Line Process Flow

Paso 1. Molinillo para aplastar la materia prima en piezas pequeñas (El diámetro es de aproximadamente 3-5 mm)

Paso 2. Secadora para secar la materia prima hasta que la humedad sea menor que 12%

Paso 3. Coloque el material en la máquina de briqueta de madera sin agregar ningún producto químico,

Paso 4. Carbonización El palo de briqueta de madera

Paso 5. El carbón terminado puede ser de 45 mm , 50mm,60mm ,70mm ,80mm de diámetro

A.Drum chipper is a special equipment for producing all kinds of high-quality wood chips. It can cut logs and small-diameter wood into high-quality wood chips with uniform size and flat cuts.

B.Double mouth crusher is a fine crushing equipment that can process all kinds of wood, restos de madera, sucursales, sucursales, chips de madera, adorno, ladrar, bambú, corteza de bambú y otras materias primas en aserrín a la vez.

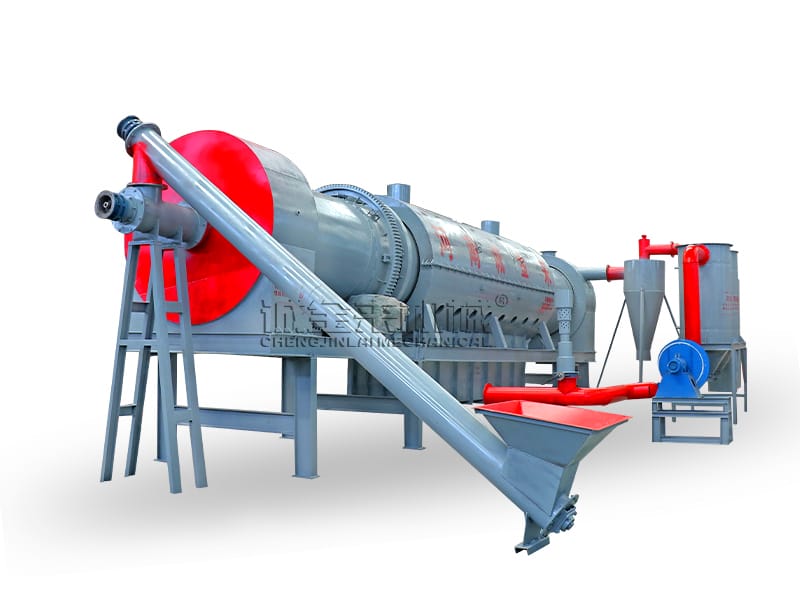

C.Rotary drum dryer is one of the traditional drying equipment, que es confiable en la operación, Flexible en funcionamiento, fuerte en adaptabilidad, y grande en capacidad de procesamiento. El diámetro y la longitud del equipo se determinan de acuerdo con los requisitos de secado.

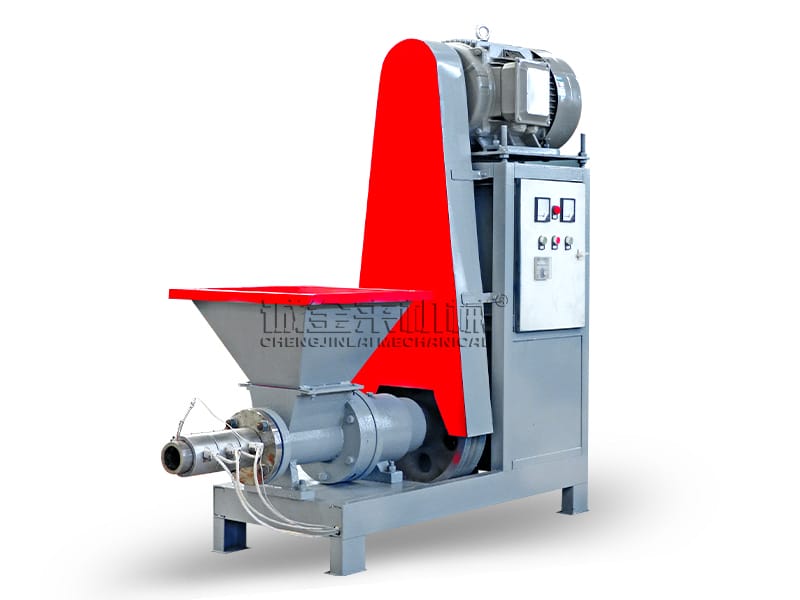

D.Wood charcoal briquette machine is a kind of forming equipment, que pasa principalmente a materiales de aserrín y madera o materiales de biomasa calificados (menos de 5 mm de tamaño, 12% humedad) a través de espirales, cilindros de formación de alta presión y anillos de calefacción. The machine-made rod is formed under high temperature and high pressure.

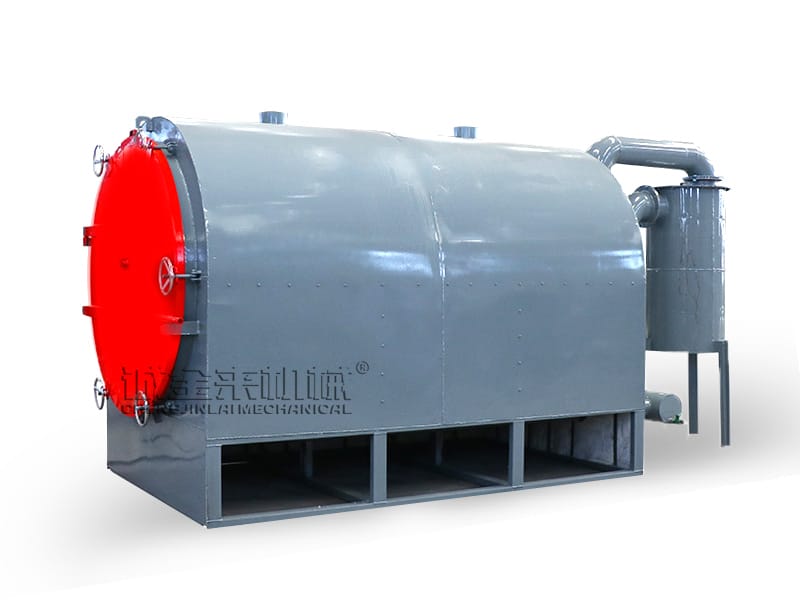

E.Hoisting carbonization furnace is an environmentally friendly and smokeless carbonization equipment. It can not only carbonize machine-made rods, but also directly carbonize raw materials such as logs, bloques de madera, cáscara de coco, and tree bark.

Proporcionamos 100% Free Charcoal Machine Production Line Design

When you plan to configure a carbonization production line, Háganos saber sus datos.

Estos materiales incluyen:

1.Tipo de materia prima, tamaño, humedad

2.Tamaño de la planta

3.Capacidad de transformador

4.Tipo y tamaño del producto terminado

5.Demanda de producción

Lo más detallado posible, el mejor, in order to customize your own carbonization production line equipment, y le proporcionaremos diagramas de planificación del sitio 3D de forma gratuita.

*Se diseñarán diferentes materiales en una solución de producción diferente., El cliente en el momento de la consulta necesita informarnos sobre los materiales’ humedad, tamaño de partícula, producir, tamaño de briquetas, forma, Algunas circunstancias especiales tal vez necesiten equipos auxiliares, como otros tipos de trituradores.,Otros tipos de mezclador,malla, tamiz de vibración, alimentador de carpetas, tanque de mezcla líquida, separador magnético, pescador de cinturón electrónico, unidad de frecuencia variable.

En resumen, the industrial wood chip charcoal block production line is an important environmental protection technology. It effectively converts wood chip resources into high-value fuel and helps achieve the goal of sustainable development. If you are interested in the equipment or have any questions, please leave a message and we will wholeheartedly provide you with professional answers and solutions!

Publicaciones relacionadas

Veloz

Veloz

+8613838093177

+8613838093177