¿Qué es la máquina extrusora de carbón??

Máquina moldeadora de briquetas de carbón puede convertir carbón y polvo de carbón en palos. Este es el primer paso para hacer carbón. La forma de los palos se puede hacer por los requisitos de los clientes. El producto final hecho por esta máquina no es contaminación ni humo. Es adecuado para polvo de carbón, polvo de carbón de madera, polvo de carbón de cáscara de coco, polvo de carbón de cáscara de arroz, polvo de carbón, polvo de carbón.

Materias primas disponibles para la máquina extrusora de carbón

Máquina moldeadora de briquetas de carbón es adecuado para carbón en polvo, polvo de carbón de madera, polvo de carbón de cáscara de coco, polvo de carbón de cáscara de arroz, polvo de carbón, etc..

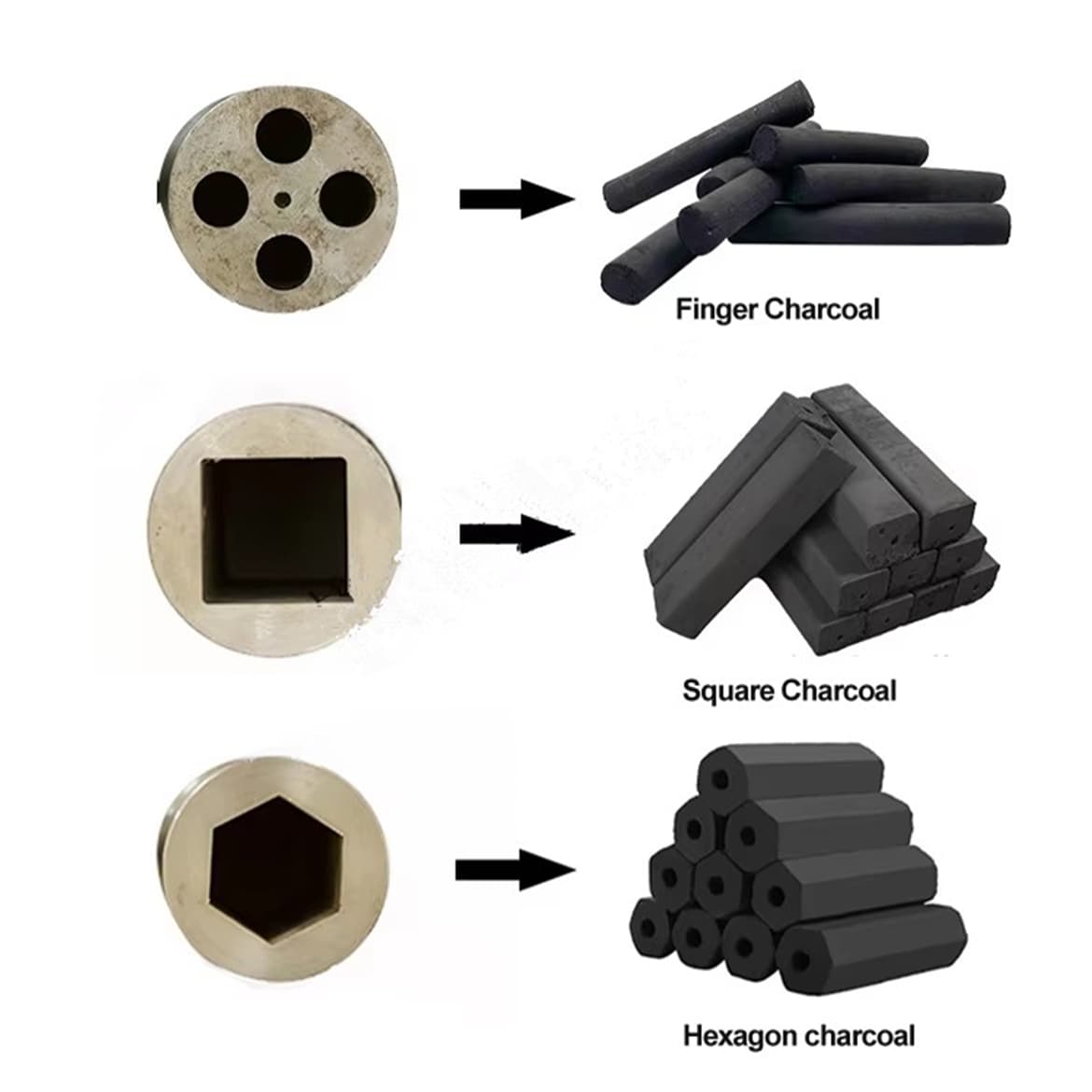

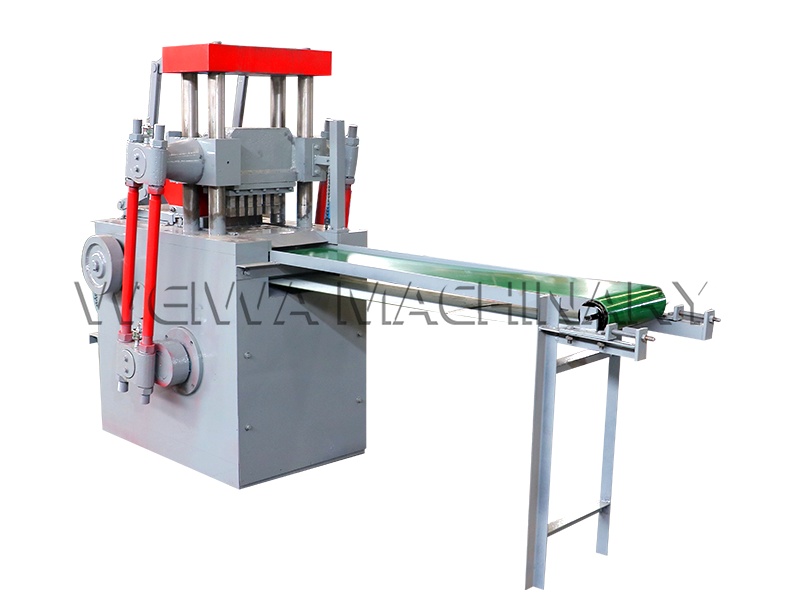

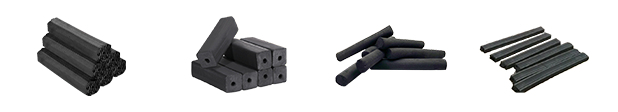

Productos finales de la máquina extrusora de carbón

Se recomienda que los clientes compren máquinas que puedan estar equipadas con moldes de diferentes formas. Los tamaños de moho normales son cilíndricos, cuadrado, hexagonal, Ronda y otras formas que le interesan.

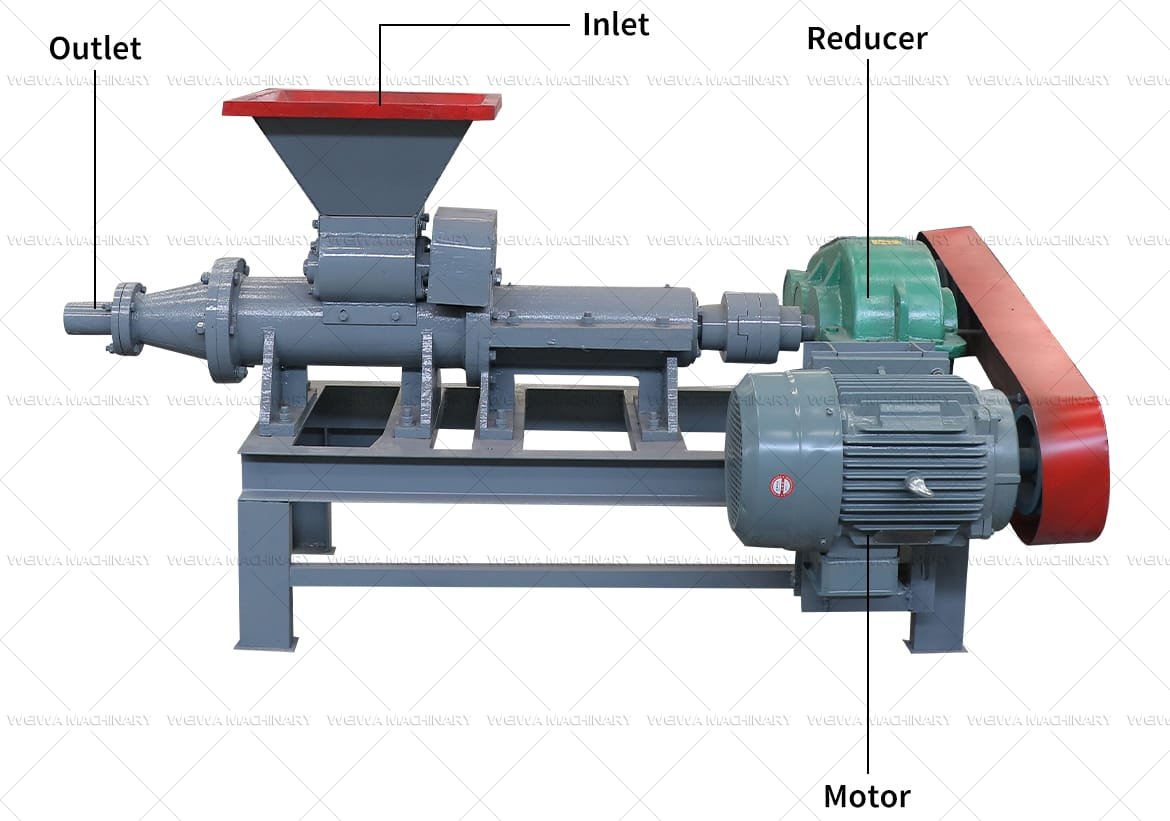

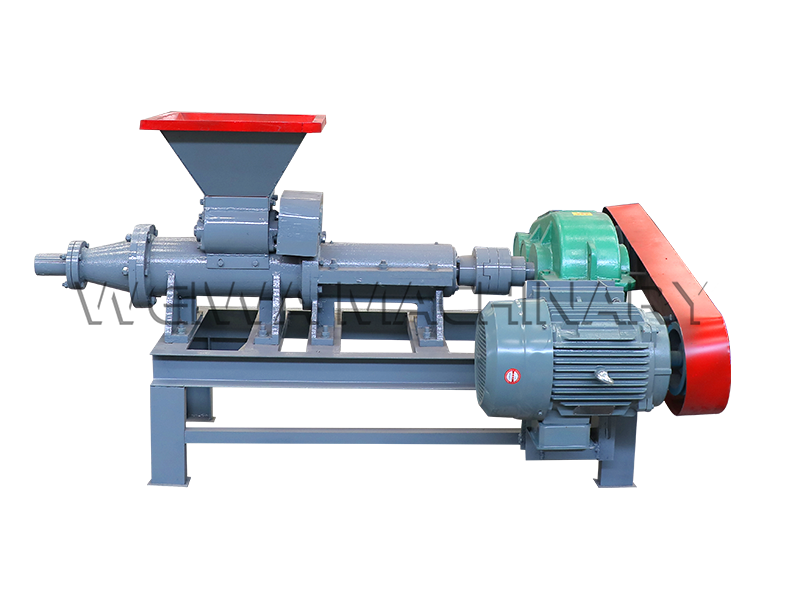

Principio de funcionamiento de la máquina extrusora de carbón

El motor transmite potencia a la transmisión a través de la correa transversal. ,y el eje de salida de la transmisión transmite potencia al eje de propulsión a través del acoplamiento flotante. La hélice en el eje de propulsión empuja el material de carbón hacia afuera a través del cabezal de formación.,y se produce la varilla de carbón de alta presión..

Característica:

1.Acero al carbono certificado nacional como base y marco de la máquina.;

2.100% motores de bobina de cobre;

3.Caja de cambios usada de alta calidad.;

4.Hélice de aleación de alto manganeso y #45 moldes de acero.

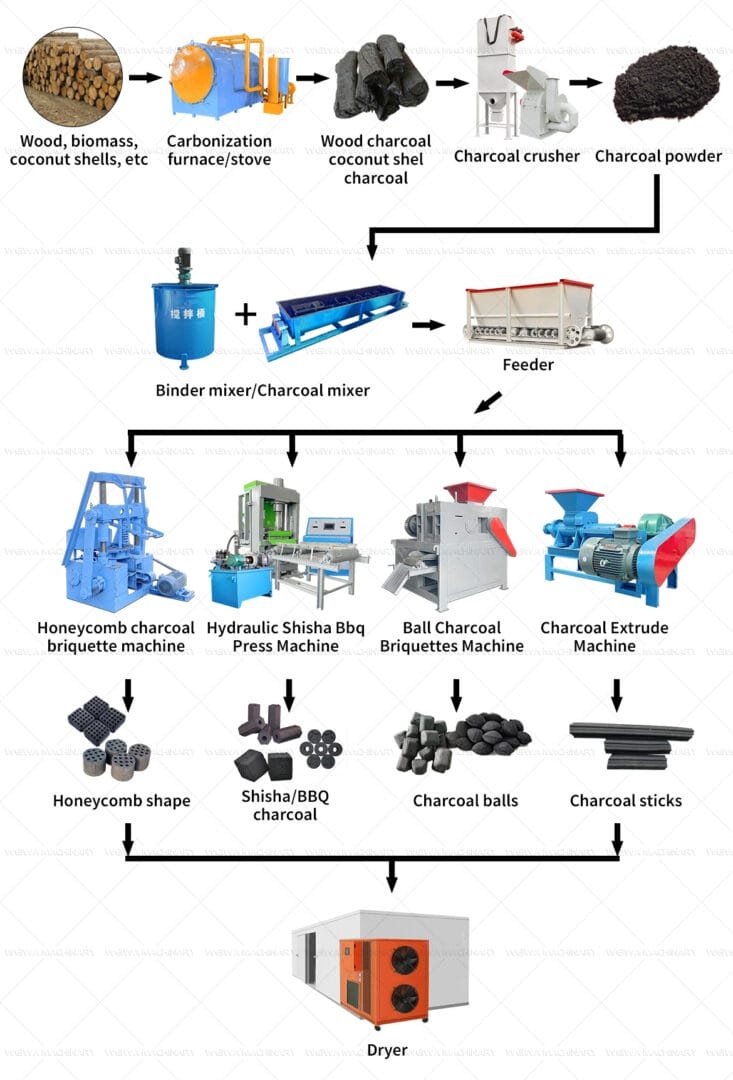

¿Cuál es el proceso de la máquina extrusora de carbón?

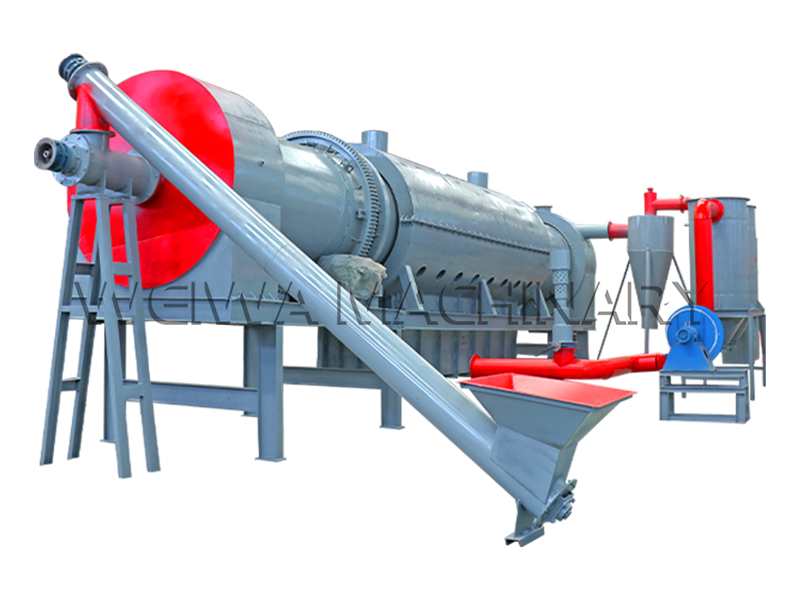

Trituradora de carbón:

Se utiliza para pulverizar carbón de biomasa hasta convertirlo en polvo.. El polvo mide menos de 3 mm. Si su materia prima mide menos de 3 mm. Puedes pasar directamente al siguiente proceso sin elegir aplastar.

Mezclador de muelas:

La mezcladora es una máquina importante en la línea de producción.. Utilizamos principalmente esta máquina para mezclar el polvo de carbón y el aglutinante.. El material procesado por esta máquina es fácil de moldear..

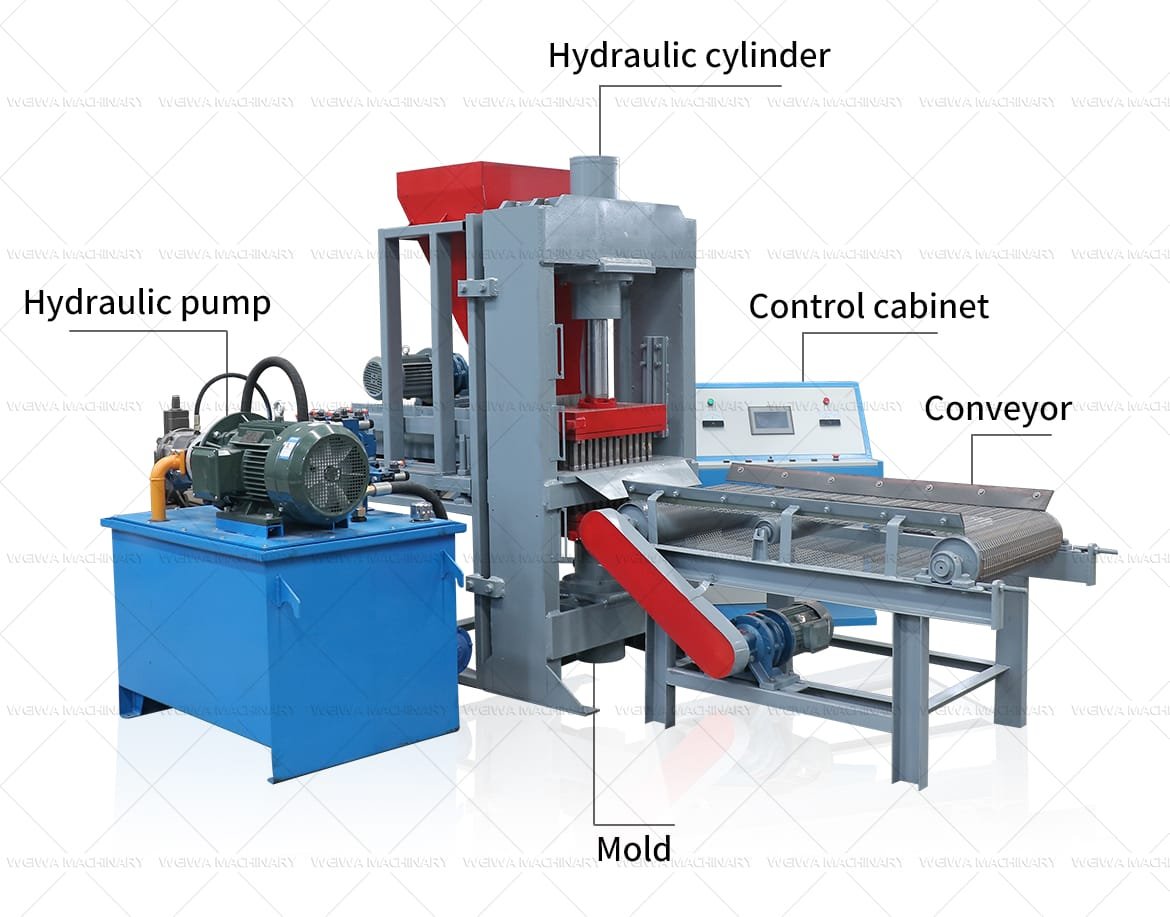

Máquina de extrudencia de carbón:

La máquina extrusora de carbón es la máquina más importante en esta línea de producción.. Se pueden producir muchas formas que desee., como cilíndrico, columna cuadrada, hexagonal, cuadrado, etc..

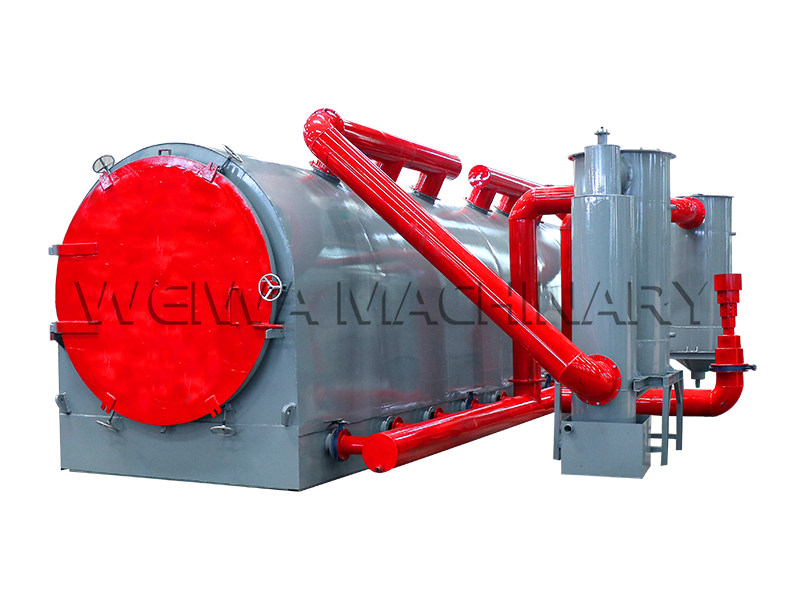

Equipo de secado:

Este equipo de secado se utiliza para secar las materias primas formadas..

¡También hay otros equipos formadores de carbón disponibles para que usted elija!

Modelos y tipos de máquinas extrusoras de carbón a la venta

| Modelo | Potencia (kilovatios)) | Capacidad(T/H) | Dimensión(metro) | Peso(kg) |

| 140 | 15 | 0.8-1.0 | 1.9*1.1*1.17 | 650 |

| 160 | 22 | 1.2-1.5 | 2.2*1.3*1.4 | 850 |

| 180 | 22-30 | 1.0-1.2 | 2.2*1.3*1.4 | 1050 |

Embalaje & Envío

Máquina moldeadora de briquetas de carbón estará envuelto con película de plástico primero (incluyendo el motor).

La máquina envuelta en bolsas de película de plástico, Según el tamaño y el peso para hacer una caja de madera o de hierro, Ponga la máquina y solucionó la caja después de cargar. (El material de la caja se puede hacer como sus requisitos)

Comenzando su negocio aquí!

Hasta ahora, Tenemos clientes más de 130 países, Indonesia, India, Malasia, Laos, Myanmar, Tailandia,Vietnam,Filipinas,Pakistán, Sri Lanka, Líbano, Georgia, Pavo, Polonia, checo, Mongolia, Corea del Sur, Rumania, Egipto, Sudán,Túnez,Argelia, Etiopía, Guinea ecuatorial de Tanzania, Zambia, México, Sudáfrica, etc..

De nada si desea visitar nuestra fábrica! Puedes contactarnos ahora!

Publicaciones relacionadas:

Veloz

Veloz

+8613838093177

+8613838093177