La creciente demanda de briquetas de carbón en Tailandia

El cambio de Tailandia hacia la energía sostenible y las soluciones de combustible ecológicas ha impulsado un aumento en la demanda debriquetas de carbón, particularmente en los hogares, restaurantes, y sectores industriales. Como resultado, Los fabricantes buscan cada vez más soluciones eficientes.máquinas extrusoras de carbónYbriquetadoras de varillas con cortadorespara producir alta calidad, briquetas de forma uniforme.

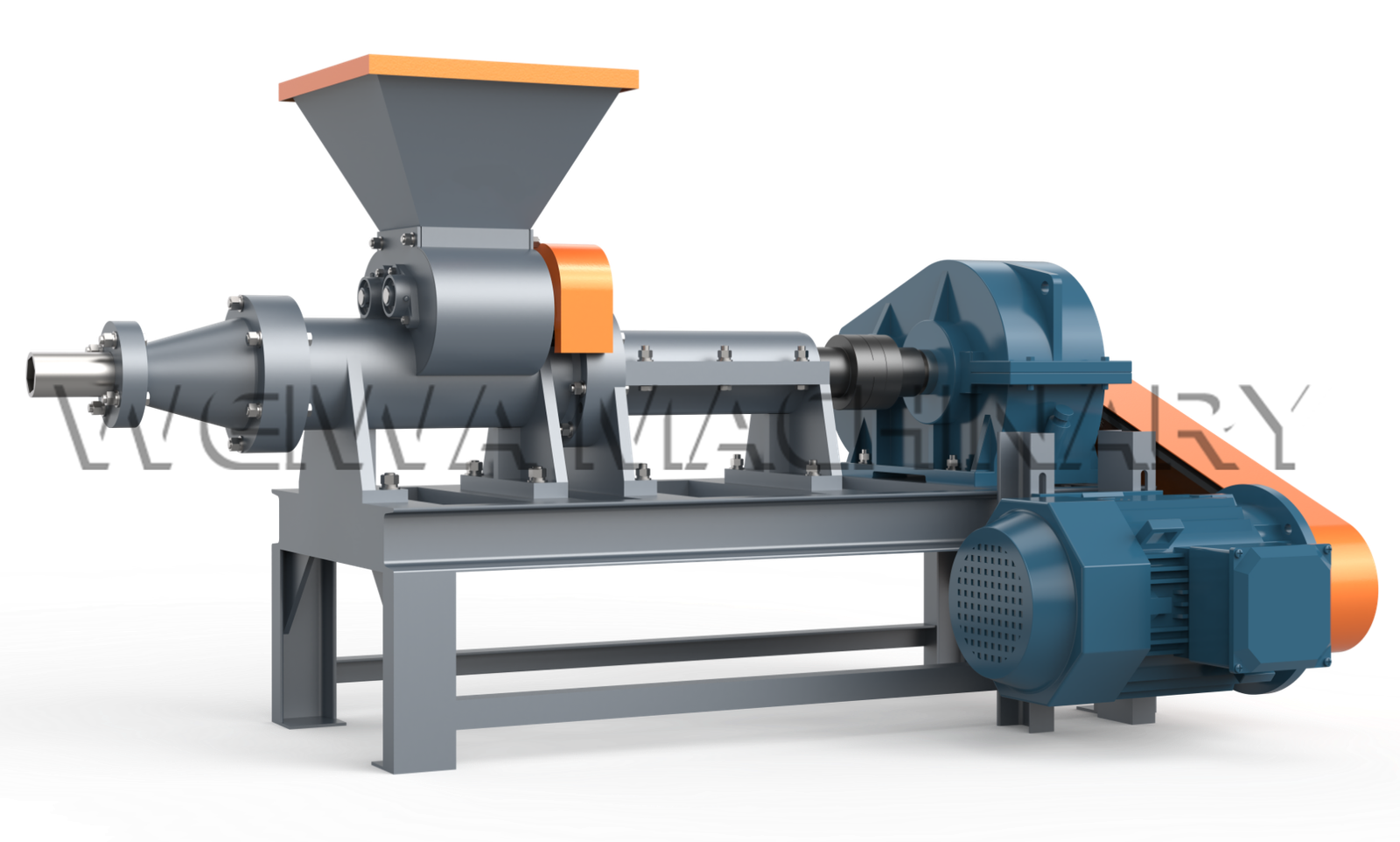

AMaquinaria de Weiwa, Recientemente realizamos una prueba in situ de nuestromaquina extrusora de carbon con cortador para un cliente tailandés, demostrando su eficiencia, durabilidad, y rentabilidad.

Cómo Máquinas extrusoras de carbón con cortador Trabajar?

El papel de las máquinas extrusoras en la producción de briquetas

Unmáquina extrusora de carbón (también llamadomáquina de varilla de carbón) comprime el polvo de carbón en barras o barras densas usando alta presión. Luego, estas varillas se secan al aire o se carbonizan para usarlas como combustible..

Nuestrobriquetadora de varillas con cortador lleva este proceso más allá Cortar automáticamente las varillas extruidas. en longitudes uniformes, Garantizar la coherencia y reducir el trabajo manual.. Esto es especialmente beneficioso para los fabricantes tailandeses que buscanalta eficiencia de producción.

Por qué los clientes tailandeses prefieren los modelos equipados con cortador?

- Corte de Precisión: Garantiza tamaños de briquetas uniformes para una mejor eficiencia de combustión.

- Ahorro de mano de obra: Elimina la necesidad de corte manual, Reducción de los costos operativos.

- Producción más rápida: La extrusión y el corte continuos mejoran la velocidad de salida.

Prueba de campo en Tailandia

Configuración de prueba & Requisitos del cliente

https://youtube.com/shorts/Cb2nP1xTiMc

Nuestro cliente tailandés, un productor de carbón de mediana escala, necesitaba unMáquina extrusora de carbón confiable con cortadorque podría manejarproducción de alta capacidadmientras se mantienebajos costos de mantenimiento. Instalamos nuestromáquina para fabricar briquetas de varillas en Tailandiay realizó un72-prueba continua de una horapara evaluar su desempeño.

Aspectos destacados del rendimiento

- Extrusión suave & Corte

- La máquina funcionó sin atascos., produciendovarillas de carbón consistentes con superficies lisas.

- Elcortador incorporadoSegmentó con precisión las varillas en5cm de longitud (ajustable según las necesidades del cliente).

- Alta eficiencia & Bajo tiempo de inactividad

- La máquina procesó1-1.5 toneladas de carbón en polvo por hora, Cumplir con los objetivos de producción del cliente..

- Desgaste mínimo de los componentes garantizadodurabilidad a largo plazo.

- Energía & Rentabilidad

- El motor consumiópoder moderado, alineándose con el clienteprecio de la máquina para fabricar carbónexpectativas de retorno de la inversión.

- Costos laborales reducidos debido a la automatización..

Precio de la máquina para fabricar carbón

Factores que influyen en el costo

Elprecio de una máquina para fabricar carbónvaría según:

- Capacidad (pequeño, medio, o producción a gran escala)

- Nivel de automatización (manual, semiautomático, o completamente automático con cortador)

- Calidad de los materiales (acero inoxidable vs.. acero carbono)

Nuestrobriquetadora de varillas con cortador ofertas precios competitivos al mismo tiempo que se garantizaalta durabilidad y rendimiento, convirtiéndolo en unSolución rentable para los fabricantes tailandeses..

ROI para clientes tailandeses

- Capacidad de producción: 1-1.5 toneladas/hora → ~8-12 toneladas/día

- Precio de mercado de briquetas de carbón en Tailandia: ~1.20 por kilogramo (dependiendo de la calidad)

- Punto de equilibrio: Normalmente dentro6-12 meses de operación.

Por qué Tailandia es un mercado clave para las briquetas de varillas?

Creciente demanda de combustible sostenible

- Hospitalidad & Industria de Restaurantes: Gran demanda de briquetas de carbón vegetal de combustión limpia.

- Uso doméstico: Los consumidores prefierensin humo, briquetas de combustión prolongada.

- Aplicaciones industriales: Utilizado en metalurgia y agricultura..

Tendencias de fabricación local

Los empresarios tailandeses están invirtiendo enmáquinas extrusoras de carbón a:

- Reducir la dependencia del carbón importado

- Crear productos con valor agregado a partir de desechos agrícolas. (P.EJ., cáscara de coco, restos de madera)

La experiencia de Weiwa Machinery en soluciones de briquetas de carbón

Nuestroprueba de campo en Tailandia confirmó que nuestro maquina extrusora de carbon con cortadorentregaalta eficiencia, durabilidad, y ahorro de costos para fabricantes locales. Si necesitas unmáquina para fabricar briquetas de varillas en Tailandiao unsolución personalizada para hacer carbón, Maquinaria Weiwa proporciona:

Maquinaria confiable con rendimiento probado

Precio competitivo de la máquina para fabricar carbón

Soporte en sitio & pruebas

Acerca de Maquinaria de Weiwa

Maquinaria de Weiwaes un fabricante líder debriquetas de carbón, extrusoras, y soluciones de briquetas con más 10+ Años de experiencia en el servicio a clientes globales. Nos especializamos en:

- Máquinas extrusoras de carbón con cortadores.

- Máquinas de briquetas de varilla (manual, semiautomático, completamente automático)

- Soluciones personalizadas para diferentes materias primas (madera, cáscara de coco, biomasa)

Con fuerte presencia enAsia, África, y el sudeste asiático, ayudamos a los clientesaumentar la eficiencia de la producción, reducir costos, y transición hacia soluciones de combustible sostenibles.

Contáctenos hoy para un consulta gratuita o demostración de la máquina adaptado a sus necesidades en Tailandia o más allá.

- Multitud:+8613838093177

- Whatsapp:+8613838093177

- Correo electrónico:info@cjlmachinegroup.com

Veloz

Veloz

+8613838093177

+8613838093177