Introducción: Why Canada Needs Advanced Charcoal Production Technology

Canada’s push for renewable energy and sustainable agriculture has created a booming demand for biomass-based charcoal solutions. As a leading manufacturer of extrusoras de aserrín, rice husk extrusion machines, y briquetas de carbón, Weiwa Machinery is proud to support this transition.

The Science Behind Biomass Charcoal Production

How Sawdust & Rice Husk Become High-Quality Charcoal

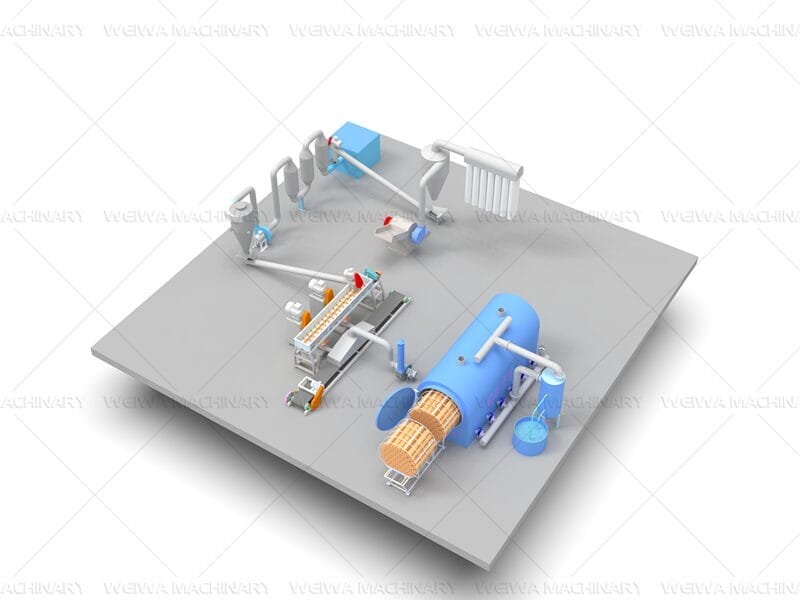

Nuestrosawdust charcoal making machine product line employs a horno de carbonización to convert organic waste into charcoal through controlled carbonization. The process involves:

- Paso 1. Molinillo para aplastar la materia prima en piezas pequeñas (El diámetro es de aproximadamente 3-5 mm)

- Paso 2. Secadora para secar la materia prima hasta que la humedad sea menor que 12%

- Paso 3. Coloque el material en la máquina de briqueta de madera sin agregar ningún producto químico,

- Paso 4. Carbonización El palo de briqueta de madera

- Paso 5. El carbón terminado puede ser de 45 mm , 50mm,60mm ,70mm ,80mm de diámetro

This method not only recycles agricultural waste but also produces clean-burning charcoal for heating, cocinando, y aplicaciones industriales.

Why Canadian Clients Chose Weiwa’s Machinery

Key Advantages of Our Charcoal Briquette Machine

The Canadian buyer selected Weiwa’s equipment for three main reasons:

- Alta eficiencia- nuestrorice husk extrude machine processes raw materials at a rate of 1–2 tons/hour, ideal for large-scale production.

- Bajas emisiones – The charcoal making machine in Canada is designed to minimize smoke and pollutants during carbonization.

- Versatility – The system accepts serrín, cáscara de arroz, and other biomass, catering to Canada’s diverse agricultural waste streams.

Instalación en el sitio & Trial Run in Canada

From Unboxing to Production: A Smooth Setup

Our technicians supervised the installation, asegurando:

- Proper alignment of the extrusora de aserrín and conveyor belts.

- Calibration of the carbonization furnace for optimal temperature control.

- Safety checks for the briquette pressing unit.

The trial run exceeded expectations, produciendouniform charcoal briquettes with 85% carbon content—a testament to our machine’s precision.

Local Impact: How This Machine Benefits Canadian Industries

From Farms to Energy Markets

The shipment addresses Canada’s need for:

- Sustainable fuel for rural households and industrial boilers.

- Waste management solutions for sawmills and rice processing plants.

- Export-ready charcoalPara mercados globales.

Feedback from the Canadian team highlights bajos costos de mantenimientoYhigh durability—key factors in their long-term partnership with Weiwa.

Conclusión: Weiwa Machinery’s Commitment to Global Sustainability

This shipment marks another milestone in our mission to provide eco-friendly charcoal solutions worldwide. By combining advanced extrusion technologyConefficient carbonization, we empower clients like our Canadian partners to turn waste into profit.

Acerca de Maquinaria de Weiwa

con más 30 Años de experiencia, Maquinaria de Weiwa specializes in biomass processing equipment, including sawdust charcoal making machines, rice husk extruders, y complete briquette production lines. Our R&D team continuously innovates to meet global sustainability goals.

Contáctenos for a customized solution tailored to your region’s needs.

- Multitud:+8613838093177

- Whatsapp:+8613838093177

- Correo electrónico:info@cjlmachinegroup.com

Veloz

Veloz

+8613838093177

+8613838093177