Introduction to Charcoal Briquette Machines

Charcoal briquette machines, como charcoal extruders, son esenciales para convertir la biomasa de los residuos o el polvo de carbón en varillas de combustible de alta densidad. These machines are widely used in Uganda for domestic and industrial applications due to their cost-effectiveness and environmental benefits.

AMaquinaria de Weiwa, we specialize in manufacturing high-performance máquinas extrusoras de carbón, máquinas extrusoras de aserrín, y briquetas de bolas designed for efficiency and durability. In this blog, we’ll explore the working principles of these machines and share insights from a recent test run of our equipment.

How Does a Charcoal Extruder Machine Work?

Key Components & Process

Unmáquina extrusina de carbón compresses raw materials (polvo de carbón, polvo de carbón, or biomass) under high pressure, forcing them through a mold to form solid briquettes. The process involves:

- Feeding System: Raw materials are fed into the machine’s hopper.

- Compression & Extrusión: A screw conveyor pushes the material into a compression chamber, where high pressure forms dense rods.

- Corte & El secado: The extruded rods are cut to size and dried for optimal combustion.

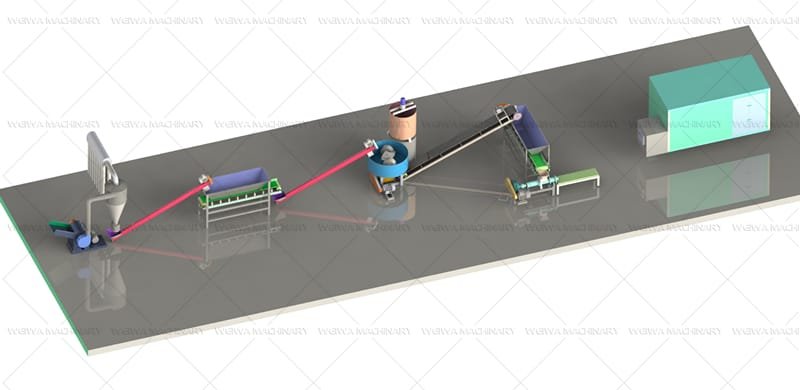

We can also customize the línea de montaje according to the customers’ requisitos.

Why Choose a Rod Briquette Machine?

Rod-shaped briquettes offer several advantages:

- Higher density for longer burning time.

- Lower smoke emissions compared to loose charcoal.

- Easier storage & transporte due to uniform shape.

Weiwa’s Charcoal Extruder Test Run: Key Findings

Configuración de prueba & Parameters

We conducted a real-world test run de nuestro máquina extrusina de carbón under typical Ugandan operating conditions. The test focused on:

- Production capacity (kg/hour)

- Energy efficiency (power consumption)

- Briquette quality (densidad, durabilidad, and burn time)

Performance Results

Our machine demonstrated:

- High output efficiency, produciendo500-1000 kg/hour depending on material moisture.

- Low power consumption, making it cost-effective for small and medium businesses.

- Consistent briquette quality, with dense, crack-free rods ideal for cooking and industrial use.

Factors Affecting Charcoal Extruder Machine Price in Uganda

When evaluating charcoal making machine prices, consider:

- Machine capacity (small-scale vs. industrial models).

- Material compatibility (polvo de carbón, serrín, o desechos agrícolas).

- After-sales support, including installation and maintenance.

Weiwa Machinery offers precios competitivos without compromising quality, ensuring a strong return on investment for Ugandan customers.

¿Por qué elegir? Maquinaria de Weiwa?

Conencima 30 Años de experiencia, Weiwa Machinery is a trusted name in briquette machine manufacturing. Nuestroexpert technical team provides:

- Soluciones personalizadas tailored to your production needs.

- On-site installation & capacitación for smooth operation.

- Reliable after-sales support, including spare parts and troubleshooting.

Si necesitas unmáquina extrusina de carbón, rod briquette press, or full production line, Weiwa delivers durable, high-performance equipment at a fair price.

Contáctenos

WhatsApp/WeChat/Tel:+86 13838093177

Correo electrónico:info@cjlmachinegroup.com

Veloz

Veloz

+8613838093177

+8613838093177