Por qué Rusia necesita tecnología avanzada de briqueting de aserrín?

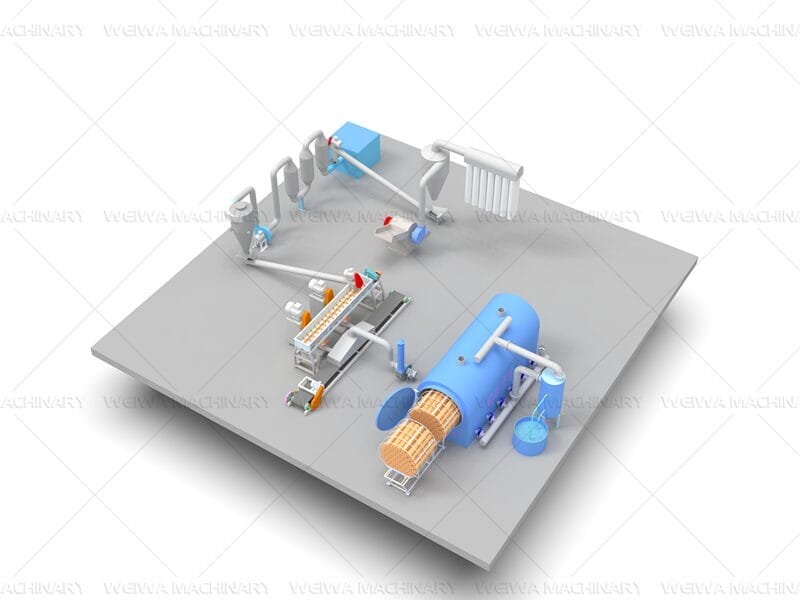

En los últimos años, Russia has seen a surge in demand for sustainable fuel alternatives, with briquetas de aserrín emerging as a key player. Como fabricante líder, Maquinaria de Weiwa recently completed the shipment of a complete wood charcoal production line to Russia, equipped with high-performance máquinas extrusoras de aserrín, Briqueta, and briquetting systems.

Understanding Sawdust Briquetting Machine

What is Sawdust Briquetting?

Sawdust briquetting is the process of compressing residuos de madera (serrín) into dense, burnable briquettes without the need for binders. These briquettes are a renewable, cost-effective alternative to traditional charcoal and firewood, making them ideal for heating, cocinando, y aplicaciones industriales.

Why Russia is Turning to Sawdust Briquettes?

Russia, with its vast forestry resources, generates massive amounts of sawdust waste. En lugar de dejar que se desperdicie, converting it into briquetas provides:

- A clean-burning fuel source (lower smoke emissions than raw wood).

- A profitable waste-to-energy solution for sawmills and biomass plants.

- Reduced reliance on imported fuels by utilizing local resources.

The Role of Máquina de extrudio de aserrín in the Production Line

How the Sawdust Extruder Works?

At the heart of our wood charcoal production linees elmáquina de extrudio de aserrín (also called a briquette extruder or sawdust briquetting machine). This equipment:

- Compresses sawdust under high pressure and heat, forming dense cylindrical briquettes (often called “briquettes sticks” o “fuel rods”).

- Does not require additional binders, as the natural lignin in wood acts as a natural adhesive when heated.

- Ensures high density and consistent shape, improving combustion efficiency.

Nuestrosawdust extrude machine in Russia is engineered to handle producción de alta capacidad, meeting the demands of both small workshops and large-scale biomass plants.

Why Our Extruder Stands Out?

- Energy-efficient design reduces operational costs.

- Construcción duradera for long-term use in demanding environments.

- Customizable output sizes to match client specifications.

From Raw Sawdust to Finished Briquettes

Paso 1: Raw Material Preparation

El proceso comienza condry sawdust (ideally 8-12% contenido de humedad). Excess moisture can hinder compression, so proper drying is essential.

Paso 2: Briquetting with Weiwa’s Sawdust Briquette Machine

Once the sawdust is prepared, it is fed into our sawdust briquette machine, where:

- High pressure and frictional heat mold the sawdust into solid briquettes.

- No chemical additives are needed, ensuring an eco-friendly product.

Paso 3: Enfriamiento & Embalaje

After extrusion, the briquettes are cooled to harden and then packed for storage or transport.

esto end-to-end sawdust briquetting system ensures maximum efficiency and minimal waste, convirtiéndolo en ungame-changer for Russia’s biomass industry.

Why Russian Clients Choose Weiwa Machinery?

1. Proven Expertise in Biomass Solutions

With years of experience in sawdust briquetting technology, Weiwa Machinery understands the unique needs of different markets, including Russia’s cold climate and vast forest resources.

2. Tailored Solutions for Local Demand

Nuestrosawdust extrude machines and briquetting lines are personalizado to match:

- Production capacity requirements (pequeño, medio, or large-scale).

- Raw material specifications (different types of sawdust, wood shavings, etc.).

3. Reliable After-Sales Support

We provide comprehensive training, guía de instalación, and maintenance support to ensure smooth operations in Russia.

The Future of Biomass Energy in Russia

As Russia continues to explore sustainable energy solutions, briquetas de aserrín are becoming a preferred choice for eco-conscious consumers and industries. With Weiwa Machinery’s advanced sawdust briquetting machines, Russian businesses can:

- Reduce waste disposal costs.

- Generate additional revenue from sawdust.

- Contribute to a greener future.

Partnering with Weiwa for Your Sawdust Briquetting Needs

The recent shipment of our wood charcoal production line to Russia highlights Weiwa Machinery’s commitment to delivering efficient, confiable, and high-quality biomass solutions. Si necesitas unmáquina de extrudio de aserrín, briquette press, or a complete production line, we have the expertise to help you succeed.

Al elegir Weiwa, you’re not just investing in machinery—you’re investing in a sustainable, rentable, and future-ready fuel solution.

Acerca de Maquinaria de Weiwa

Maquinaria de WeiwaEs unleading manufacturer of biomass briquetting and charcoal production equipment, especializado ensawdust briquette machines, extrusoras, y líneas de producción completas. ConAños de experiencia, global exports, and a focus on innovation, we help clients worldwide turn waste into valuable fuel.

Our mission is to provide rentable, durable, and efficient solutionsParaenergía de biomasa, charcoal production, and waste recycling.

Contáctenos hoy para conocer más sobre nuestro sawdust briquetting machines and how we can support your business in Russia or beyond.

- Multitud:+8613838093177

- Whatsapp:+8613838093177

- Correo electrónico:info@cjlmachinegroup.com

Veloz

Veloz

+8613838093177

+8613838093177