Meeting Saudi Arabia’s Growing Demand for Sustainable Charcoal

En los últimos años, Saudi Arabia has seen a rising demand for carbón de alta calidad, particularmente paraShisha use, due to its clean burn and aromatic properties. Palm leaves, an abundant agricultural waste in the region, present a sustainable and cost-effective raw material for charcoal production. Sin embargo, traditional carbonization methods are inefficient, time-consuming, and produce inconsistent results.

That’s where Maquinaria de Weiwa comes in. We recently completed a successful trial run of our horno de carbonización continua for a Saudi client, specifically designed to carbonize palm leaves and produce premium charcoal using a hydraulic press.

Why Continuous Carbonization Furnace is the Best Choice for Palm Leaf Carbonization

The Challenge with Traditional Carbonization Methods

Conventional batch carbonization ovens require long processing times, frequent manual intervention, and often lead to incomplete carbonization, resultando enlow-quality charcoal with high moisture content. For Saudi clients aiming to produce Shisha/Hookah charcoal, consistency and purity are crucial—factors that traditional methods struggle to deliver.

Weiwa’s Continuous Carbonization Furnace

Nuestrohorno de carbonización continuaEstá diseñado paraprocess palm leaves continuously, asegurandosteady output, eficiencia energética, and superior charcoal quality. Unlike batch systems, our furnace:

- Operates non-stop, reducing downtime and labor costs.

- Maintains optimal temperature control for uniform carbonization.

- Minimizes smoke and emissions, making it environmentally friendly.

- Handles large volumes of palm leaves, ideal for industrial-scale production.

This makes it the ideal solution for Saudi Arabia’s charcoal industry, where efficiency and scalability are key.

Customized Solution for Saudi Clients

Understanding the Saudi Client’s Needs

Our Saudi client approached Weiwa Machinery with a specific requirement: to convert palm leaves into charcoal suitable for shisha charcoal use. The challenge was to find a confiable, high-capacity carbonization system that could process palm leaves efficiently and integrate with a hydraulic press for charcoal shaping.

Our Tailored Approach

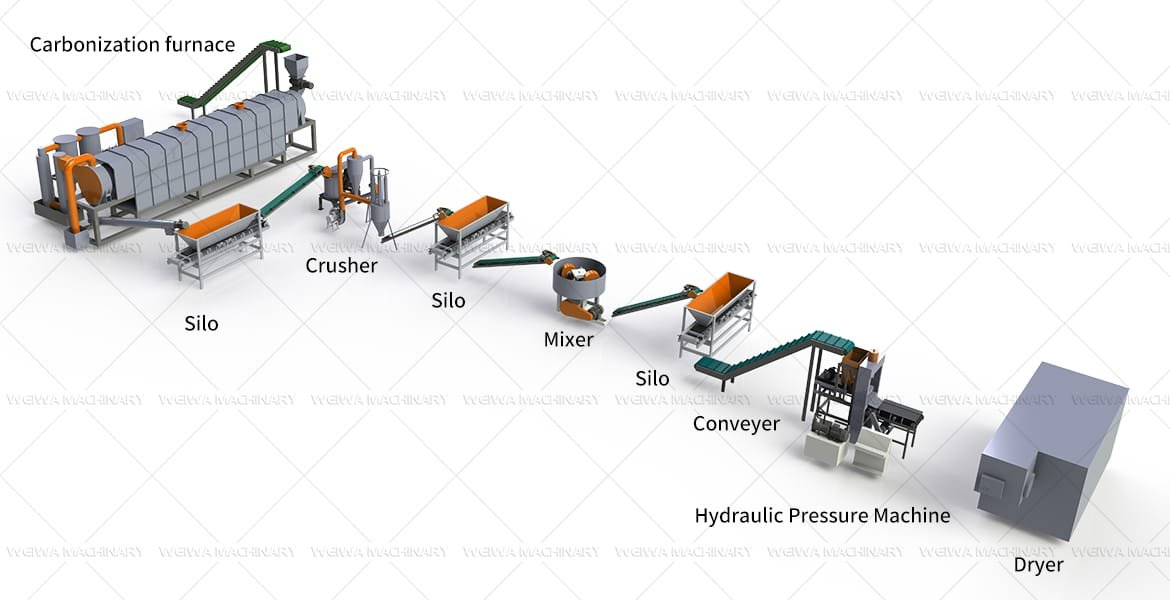

After analyzing the client’s requirements, Weiwa Machinery designed and manufactured a custom continuous carbonization furnace with the following features:

- Optimized carbonization chamber for palm leaves, asegurandocomplete pyrolysis without ash residue.

- Automated feeding and discharge systemParanon-stop operation.

- Integrated cooling and collection system to maintain charcoal quality.

- Compatibility with hydraulic pressParashisha charcoal molding.

Eltrial run confirmed that our furnace could produce high-density, low-ash charcoal with excellent combustion properties—perfect for the Saudi market.

El proceso de carbonización

1. Feeding Palm Leaves into the Furnace

Elhorno de carbonización continua is fed with dried palm leaves at a controlled rate, asegurandoeven carbonization without overloading the system.

2. Carbonization Stage

Inside the furnace, palm leaves undergo high-temperature pyrolysis (300°C–600°C), breaking down organic matter into biochar (carbón) while releasing volatile gases. Our furnace recovers these gases for energy efficiency, Reducción de los costos operativos.

3. Cooling and Collection

El resultantecarbón is automatically cooled and collected, asegurandono re-oxidation and maintaining high fixed carbon content.

4. Hydraulic Pressing for Shisha Charcoal

The final step involves compressing the charcoal into uniform shisha briquettes using a hydraulic press, asegurandoconsistent size, densidad, and burn time—key factors for customer satisfaction in Saudi Arabia.

Why Saudi Arabia is the Perfect Market for Our Continuous Carbonization Furnace

Abundant Palm Leaf Waste

Saudi Arabia has millions of date palms, produciendolarge quantities of palm leaves that are often discarded. Our furnace turns this waste into a profitable resource, apoyandosustainable agriculture and waste management.

Growing Demand for Premium Charcoal

With the rise of narguile (shisha) culture in the Middle East, there is a strong demand for high-quality charcoal that burns cleanly and lasts long. Nuestrohorno de carbonización continua ensures consistent, premium-grade charcoal that meets these standards.

Eficiencia Energética & Beneficios ambientales

Our furnace minimizes smoke emissionsYrecovers waste heat, making it ecológico and compliant with Saudi environmental regulations.

Your Partner in Advanced Charcoal Production

Elsuccessful trial of our continuous carbonization furnace in Saudi Arabia proves that Weiwa Machinery is at the forefront of innovador, sustainable charcoal production solutions. Nuestrocustom-designed furnace not only efficiently carbonizes palm leaves but also integrates seamlessly with hydraulic pressingParahigh-quality shisha charcoal.

For Saudi clients and businesses worldwide looking to upgrade their charcoal production process, Ofertas de maquinaria de Weiwa:

30+ years of expertise in carbonization technology

Custom-designed furnaces tailored to your raw materials

Professional after-sales support and on-site training

Complete planning, including design drawings and site layout

Acerca de Maquinaria de Weiwa

Conencima 30 Años de experiencia en fabricación máquinas de fabricación de carbón, Weiwa Machinery is a trusted name in the biomass carbonization industry. We specialize in custom-designed hornos de carbonización continuos, hydraulic presses, y complete production line solutions for clients in Saudi Arabia, the Middle East, y más allá.

Nuestroprofessional after-sales team garantiza una instalación sin problemas, capacitación, and ongoing support. Si necesitas unturnkey project or a customized solution, Weiwa Machinery is your reliable partner in efficient, eco-friendly charcoal production.

Get in touch with us today for a quote or consultation—we’re here to help you succeed in the charcoal business.

- Multitud:+8613838093177

- Whatsapp:+8613838093177

- Correo electrónico:info@cjlmachinegroup.com

Veloz

Veloz

+8613838093177

+8613838093177