Apakah Anda mencari mesin pembuat arang sekam padi untuk dijual? Silakan lihat grup Weiwa! Kami dapat memberikan solusi dan mesin yang paling cocok untuk Anda. Datang dan ikuti kami untuk belajar tentang mesin di sini.

Apa itu mesin pembuat arang sekam padi?

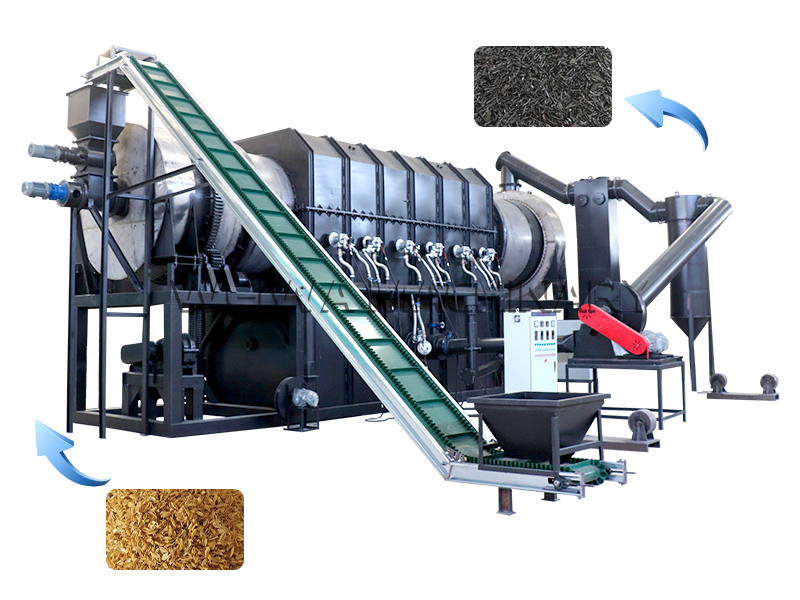

Mesin pembuat arang sekam padi mengubah limbah pertanian (KULUT NAS) menjadi biochar melalui karbonisasi suhu tinggi. Proses ramah lingkungan ini mengurangi limbah dan menciptakan energi terbarukan. Dengan jutaan ton sekam beras yang dibuang setiap tahun, Metode pembuangan tradisional seperti pembakaran atau tempat pembuangan sampah membahayakan lingkungan. Mesin pembuat arang sekam padi menawarkan solusi berkelanjutan dengan mengubah limbah menjadi produk yang berharga.

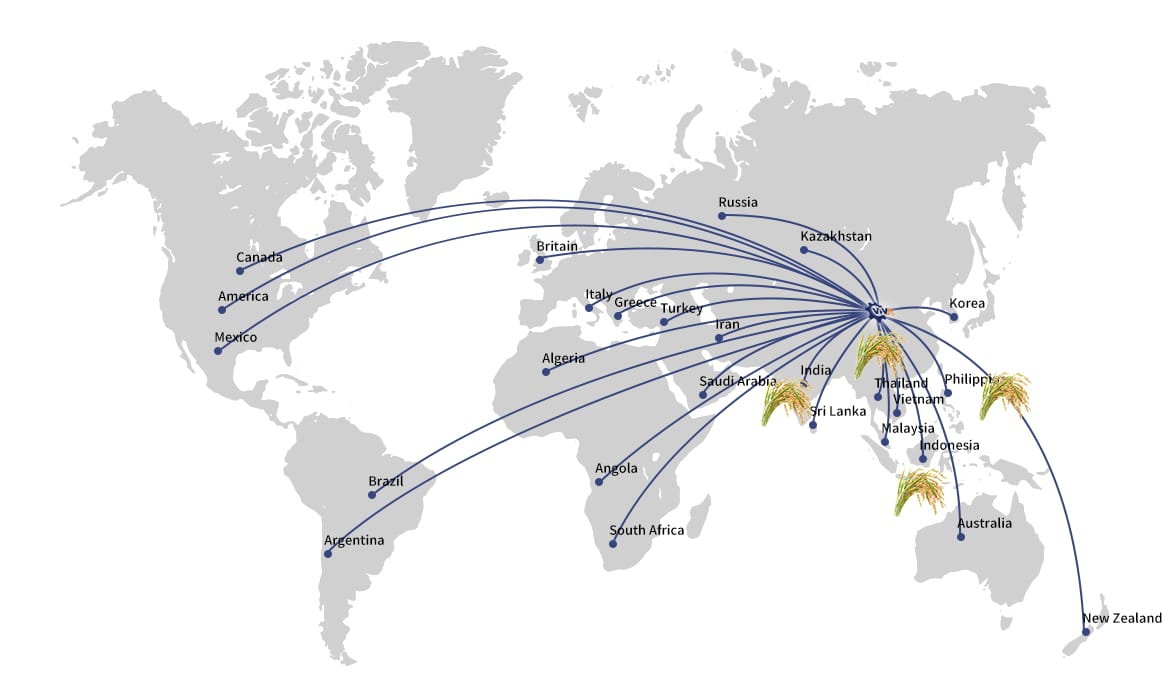

Latar Belakang Industri Produksi Beras

Berikut adalah negara -negara teratas di dunia untuk produksi beras per hektar di 2024:

Pembuangan sekam padi Tantangan saat ini

Tingkat daur ulang yang rendah

Sekitar 150 Juta ton sekam padi dihasilkan di seluruh dunia setiap tahun. Namun, Tingkat daur ulang sekam padi kurang dari 25%. Kurangnya sistem daur ulang dan infrastruktur yang efektif adalah alasan utama. Sebagai akibat, Sekam padi sering ditinggalkan atau tidak sepenuhnya dimanfaatkan.

Teknologi yang belum matang

Saat ini, Teknologi pemrosesan sekam padi yang tersedia tidak efisien. Misalnya, Insinerasi untuk energi atau pengomposan sederhana tidak dapat sepenuhnya mengetuk nilai potensial sekam padi. Teknologi pemrosesan yang lebih maju, seperti karbonisasi biomassa, belum banyak digunakan.

Masalah kelayakan ekonomi

Daur ulang berskala besar dari sekam padi sering melibatkan biaya pihak ketiga yang tinggi. Itu termasuk koleksi, biaya transportasi dan pemrosesan. Biaya ini mungkin terlalu tinggi untuk petani padi dan pengolahan tanaman. Sebagai akibat, Alasan kelayakan ekonomi menghalangi praktisi dari daur ulang.

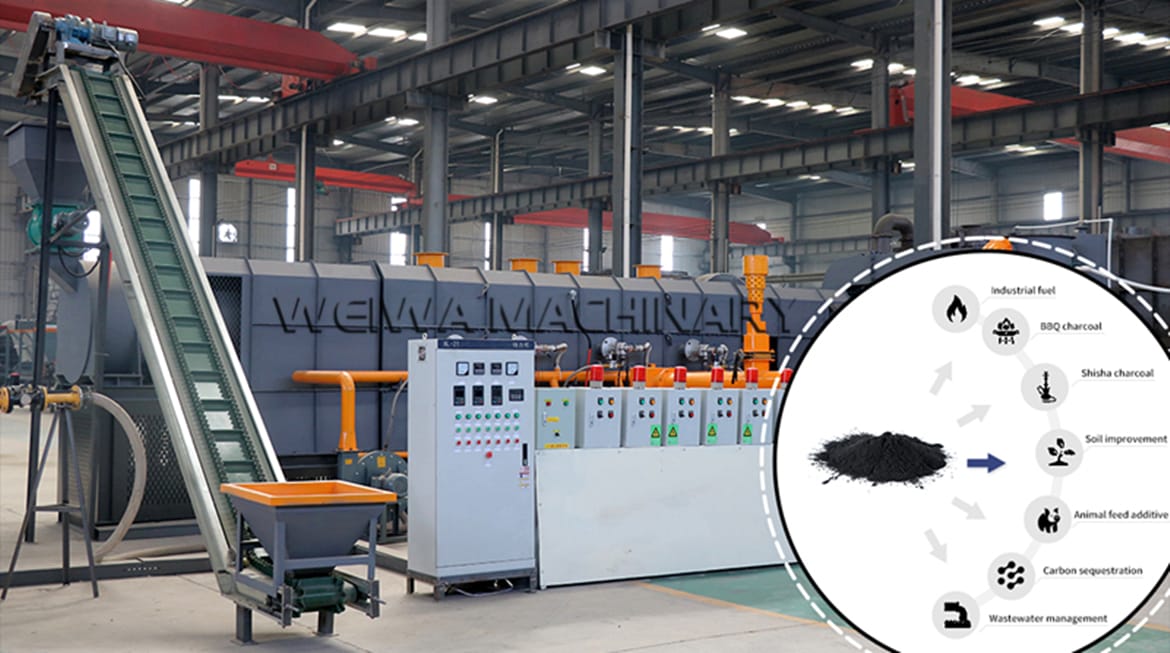

Solusi berkelanjutan: Mesin pembuat arang sekam padi

-1.jpg)

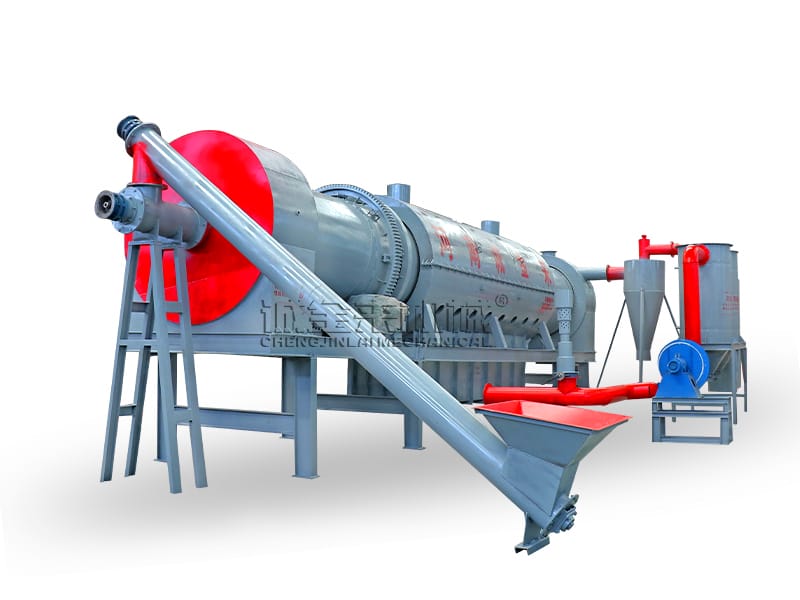

KULUT NAS Mesin Pembuat Arang adalah larutan daur ulang limbah pertanian arus utama saat ini. Itu disukai oleh pendaur ulang untuk keramahan lingkungan dan efisiensi tinggi. Mesin mencapai pengurangan sekam padi dan pemanfaatan sumber daya.

Dengan menggunakan mesin pembuat arang sekam padi, kita bisa mendapatkan produk akhir yang paling penting, arang sekam padi. Arang dapat diproses lebih lanjut menjadi hookah industri atau arang barbekyu, keduanya memiliki nilai tinggi dan dapat diterapkan di banyak area. Ini adalah mesin yang paling cocok untuk arang hookah atau produksi arang BBQ.

Hookah Charcoal

BBQ Charcoal

Cara menggunakan mesin pembuat arang sekam padi?

Fitur mesin pembuat arang sekam padi

Dilengkapi dengan perangkat alarm

Kabinet listrik PLC memiliki perangkat alarm, Dan akan ada tampilan alarm dan alarm untuk beberapa kegagalan listrik.

Dengan segel air tahan ledakan

Ada segel air tahan ledakan di pipa yang mudah terbakar (untuk mencegah tekanan abnormal gas yang mudah terbakar di dalam peralatan)

Panduan Kipas Frekuensi Variabel

Arah gas di semua pipa dipimpin oleh kipas (Kipas adalah frekuensi variabel), dan itu akan ditampilkan di PLC saat pipa diblokir.

Efisiensi panas yang tinggi

Bahannya tidak berhubungan dengan gas buang dan tidak tercemar oleh udara panas.

Efek hemat energi yang baik

Tingkat pemanfaatan panas peralatan ini lebih tinggi, Penggunaan ex-changer panas udara dapat secara efektif meningkatkan efisiensi termal dengan 5-10%, dan efek hemat energi bagus.

Dapatkan manfaat dari mesin arang sekam padi

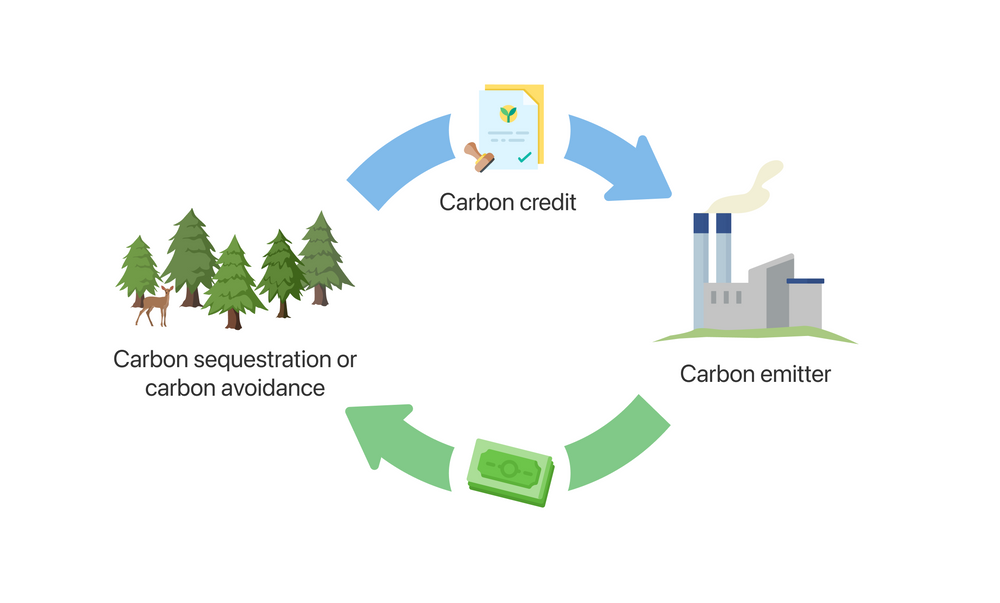

Akses terjamin ke perdagangan kredit karbon

Biochar yang diproduksi setelah sekam padi dirawat oleh tungku karbonisasi kontinu memiliki struktur karbon yang stabil dan dapat disimpan di tanah selama ratusan tahun, Mengurangi karbon dioksida di atmosfer. Proses ini sejalan dengan kategori "penghapusan karbon" atau "sekuestrasi karbon" dalam proyek kredit karbon, dan dapat diterapkan kredit karbon melalui sertifikasi internasional (seperti VC, GS, dll.)

Output arang sekam padi berkualitas tinggi

Proses karbonisasi kami menggunakan karbonisasi suhu tinggi, menjamin produksi biochar yang memenuhi standar EBC. Rasio Molar H/C Produk, Konten logam berat, dan level PAHS selaras dengan persyaratan untuk berbagai skenario aplikasi EBC, memastikan kualitas biochar superior untuk beragam penggunaan.

Perbaikan tanah

- 80% Struktur mikro untuk meningkatkan aerasi dan drainase tanah

- Memberikan beberapa elemen jejak, seperti kalium, magnesium, seng

- Alkalinitas dan pertukaran ion membantu menyesuaikan pH tanah dan menghemat biaya pupuk

Produk terkait

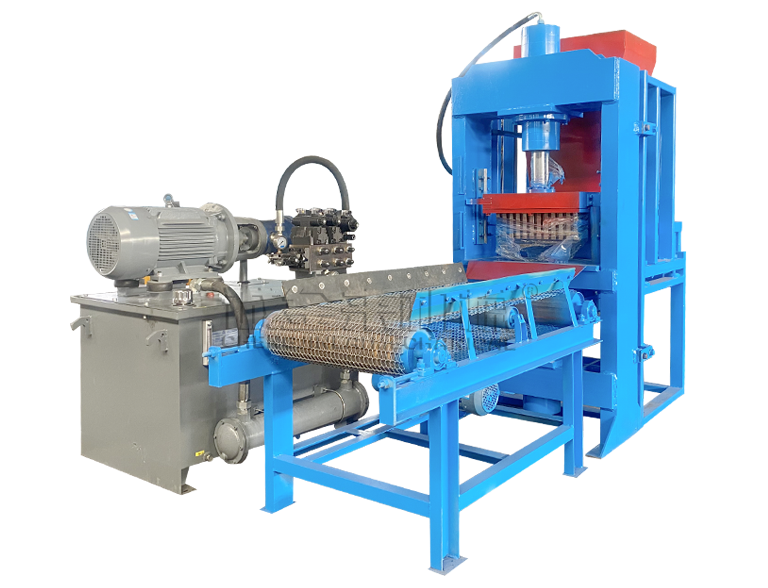

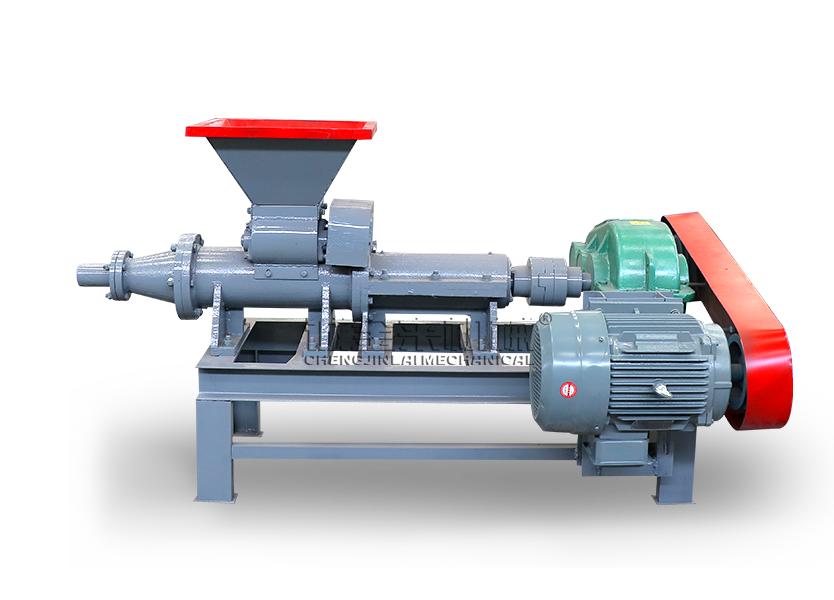

Berbagai jenis peralatan karbonisasi

Efek karbonisasi yang lebih baik, tingkat karbonisasi yang lebih tinggi 304 bahan stainless untuk tungku dalam. Resistensi suhu tinggi.

Kandungan karbon tetap yang lebih tinggi.

Cocok untuk bahan besar seperti kayu kayu.

Struktur sederhana,mudah dioperasikan dan dipelihara dapat dikendalikan dan dapat disesuaikan

suhu karbonisasi

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177