Mesin Pembuat Arang Kernel Palm Kernel Dirancang untuk Mengubah Limbah Kernel Palm Kernel menjadi arang melalui proses karbonisasi biomassa. Sebagai pelopor di limbah pembuatan pabrik daur ulang limbah, Weiwa Group dapat memberi Anda mesin arang kernel kulit palem berkualitas terbaik dengan desain yang sempurna, yang dapat menghemat energi dan melindungi lingkungan.

Ketahui cangkang kernel palem dalam penanaman kelapa sawit dan industri minyak kelapa sawit

Palm Kernel Shell (PKS) adalah kulit luar yang keras dari buah kernel palem, yang tertinggal sebagai produk sampingan setelah ekstraksi minyak sawit. Itu adalah fibrous, bahan kuning kecoklatan dengan ukuran partikel biasanya mulai dari 5 mm to 40 mm. Setiap tahun, Industri minyak kelapa sawit menghasilkan 5 Juta ton PKS. Memanfaatkan mesin biochar shell kernel palem memungkinkan Anda mendapat untung dari harga arang kernel kernel yang menarik. Sekarang pelajari tentang materi ini.

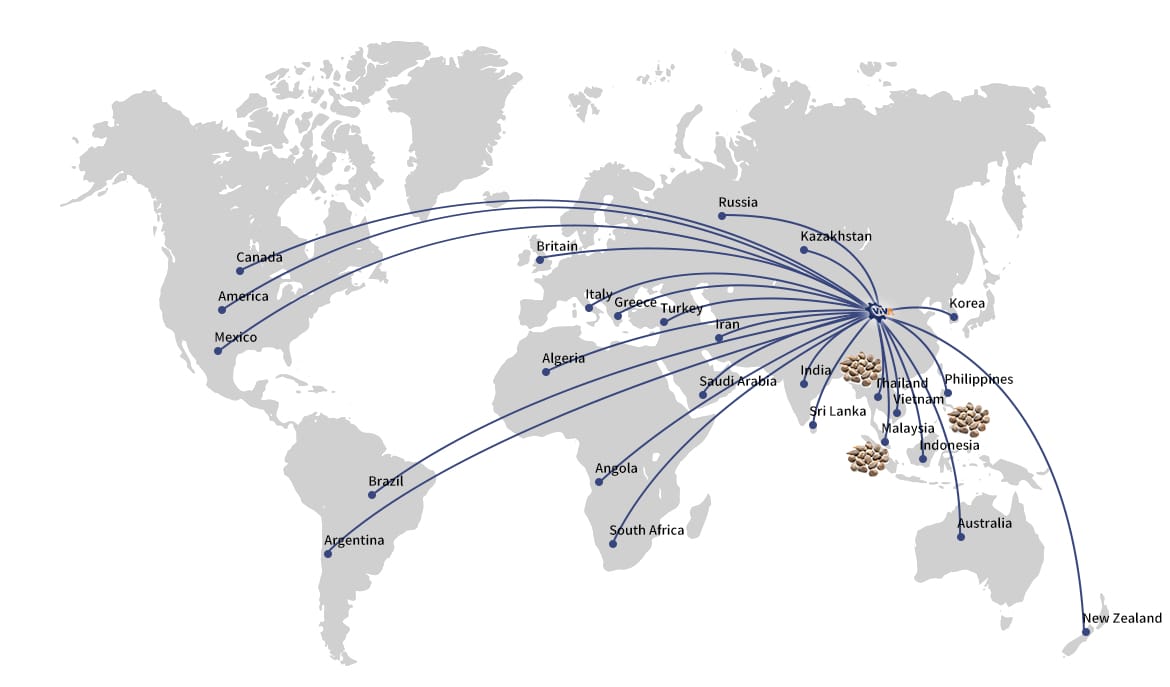

Daerah penghasil utama

Produsen utama PKS adalah negara -negara di mana kelapa sawit adalah tanaman ekonomi utama. Menurut data publik, Daerah penghasil PKS teratas termasuk:Indonesia、Malaysia 、Thailand dan dll.

Karakteristik cangkang palem

Cangkang kernel palem menawarkan karakteristik unik yang membuatnya ideal untuk produksi arang.

- Nilai kalori tinggi (sekitar 4000 Kcal/kg)

- Kadar air rendah

- Mudah dihancurkan

- Kandungan abu rendah

- Dapat diperbarui, mudah tersedia dan berbiaya rendah

Produk sampingan palem untuk karbonisasi

Selain PKS, Beberapa produk sampingan palem lainnya diproses melalui karbonisasi

- Serat kelapa sawit;

- Tandan buah kosong (EFB);

- Palm Dregs;

- Cabang dan Daun Palm;

- dll..

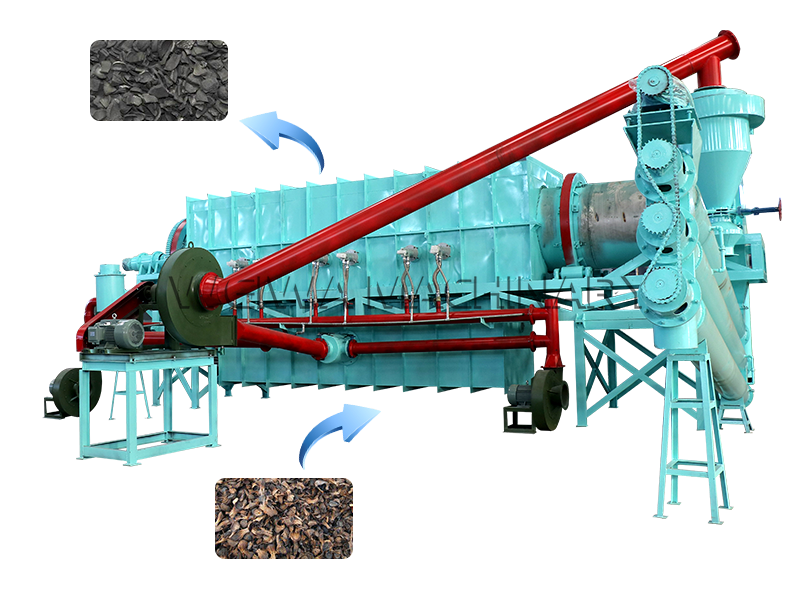

Cara menggunakan mesin pembuatan arang cangkang kernel palem?

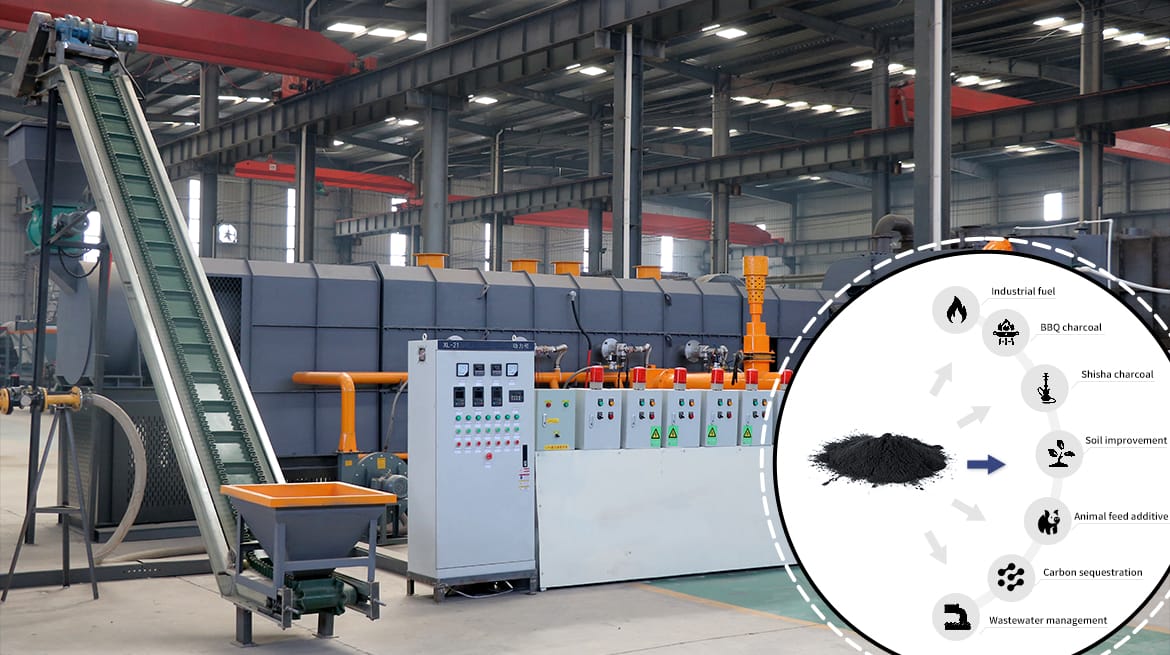

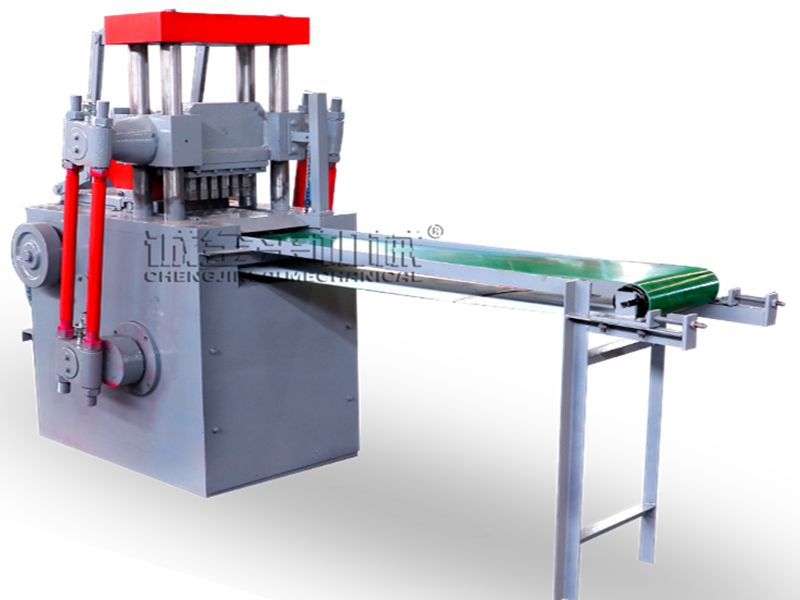

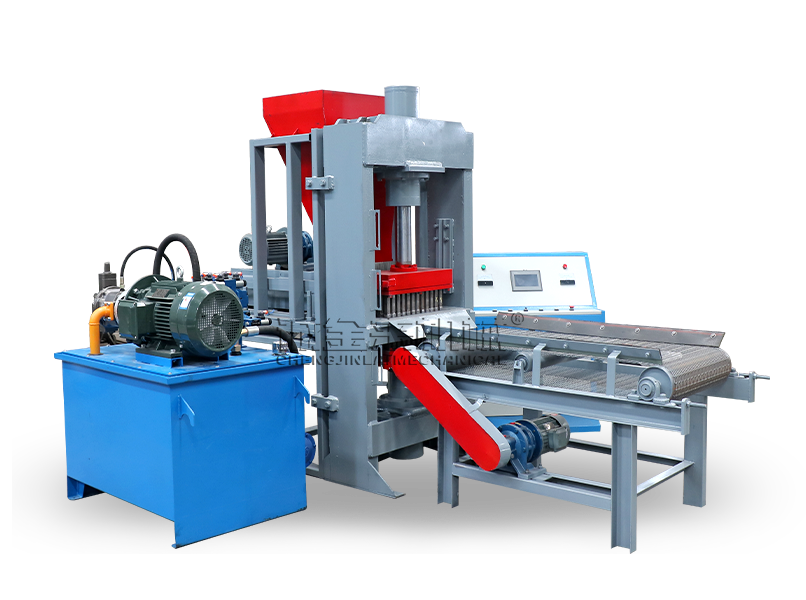

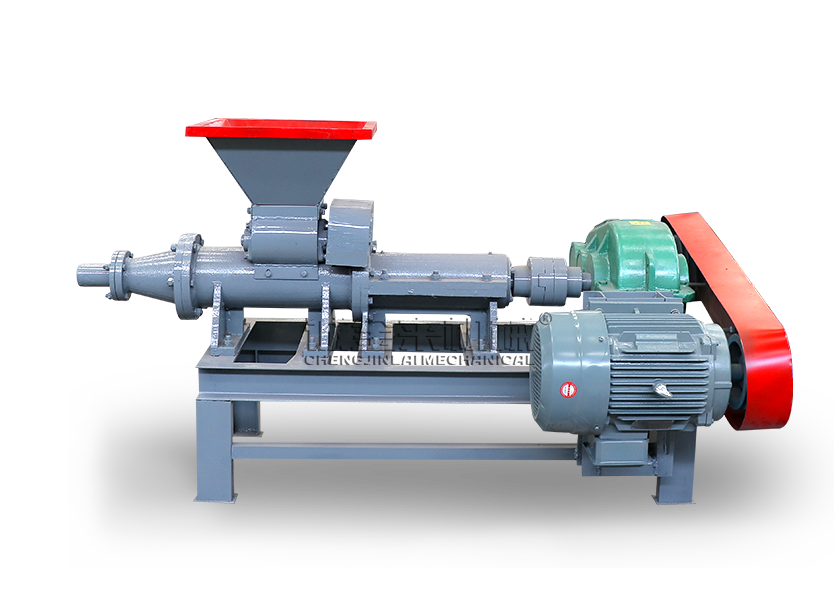

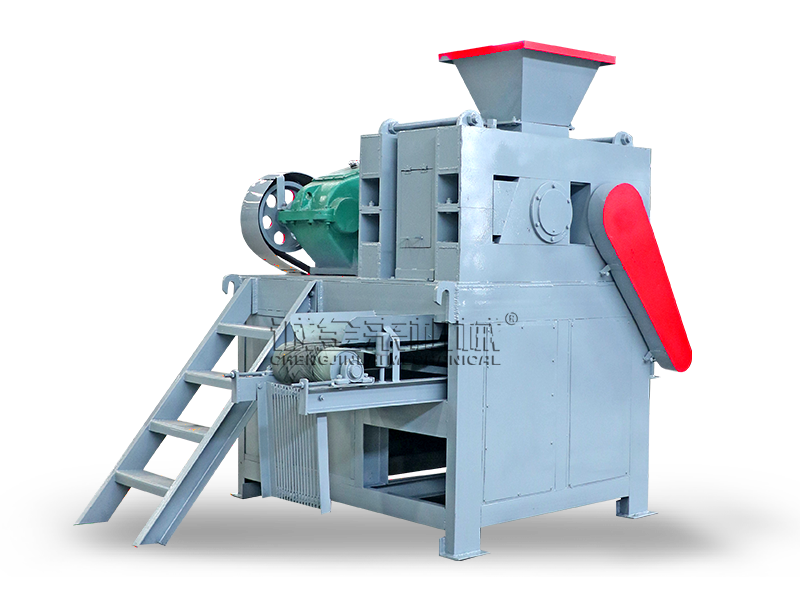

Mesin arang cangkang kernel palem lengkap biasanya mencakup garis pretreatment material, bagian karbonisasi biomassa, Dan mesin briket arang. Sistem terintegrasi ini secara efektif mengubah limbah kelapa sawit menjadi arang berharga, Mengoptimalkan proses efisiensi dan keberlanjutan. Lihat proses kerjanya.

Fitur Mesin Arang Palm Kernel Shell

Dilengkapi dengan perangkat alarm

Kabinet listrik PLC memiliki perangkat alarm, Dan akan ada tampilan alarm dan alarm untuk beberapa kegagalan listrik.

Dengan segel air tahan ledakan

Ada segel air tahan ledakan di pipa yang mudah terbakar (untuk mencegah tekanan abnormal gas yang mudah terbakar di dalam peralatan)

Panduan Kipas Frekuensi Variabel

Arah gas di semua pipa dipimpin oleh kipas (Kipas adalah frekuensi variabel), dan itu akan ditampilkan di PLC saat pipa diblokir.

Efisiensi panas yang tinggi

Bahannya tidak berhubungan dengan gas buang dan tidak tercemar oleh udara panas.

Efek hemat energi yang baik

Tingkat pemanfaatan panas peralatan ini lebih tinggi, Penggunaan ex-changer panas udara dapat secara efektif meningkatkan efisiensi termal dengan 5-10%, dan efek hemat energi bagus.

Keuntungan Mesin Arang Shell Palm Kernel

Laporan Uji Palm Kernel Shell Charcoal

Catatan: Berikut ini adalah data uji untuk Biochar Shell Palm yang diproduksi oleh Mesin Arang Kernel Palm. Data dapat bervariasi karena perbedaan material.

- Ukuran: 5-20mm

- Nilai kalor: tinggi, sekitar 5500kcal/kg

- Karbon tetap: tinggi, tentang 77%

- Kandungan belerang: sangat rendah, di bawah 0.1% (sangat rendah dibandingkan dengan kokas biasa).

- Materi yang mudah menguap: tentang 10%

- Kadar air: di antara 1% Dan 2%.

| Baik | Butir sutra palem |

| Seluruh air mt% | 2.35 |

| Air analitik gila% | 1.32 |

| Basis kering Ash Ad% | 20.75 |

| Materi volatile vd% | 9.32 |

| Basis kering fcad karbon fcad% | 68.61 |

| Kandungan belerang di basis kering st.d% | 0.42 |

| Karakteristik Coking 1-8CRC | 1 |

| Kalorimeter Kalorimeter Nasional Baru Nilai Kalori Tinggi KCAL/KG | 5485 |

| Metode Kalorimeter Standar Nasional yang baru menerima nilai rendah kalori Nilai Kkal/kg rendah | 5265 |

| Perkataan: Data di atas hanya untuk referensi |

Bidang aplikasi arang shell kernel palem

Sifat kimia unik arang cangkang kernel palem membawa berbagai aplikasi dan nilai ekonomi yang signifikan. Arang kerang Palm Kernel banyak diterapkan di pertanian, farmasi, sipil, dan industri lainnya. Ayo memulai investasi mesin pembuatan arang cangkang kernel palem!

Sekuestrasi karbon

Fitur: Kandungan karbon yang berlimpah dan struktur kimia yang stabil

Aplikasi: Sekuestrasi karbon dan kredit karbon

Palm kernel shell kandungan karbon tinggi dan struktur kimia yang stabil membuatnya cocok untuk inisiatif penyerapan karbon. Ini dapat digunakan untuk menangkap dan menyimpan karbon dioksida, Berkontribusi pada upaya yang bertujuan untuk mengurangi perubahan iklim. Selain itu, Ini dapat menghasilkan kredit karbon untuk organisasi yang terlibat dalam program offset karbon.

Bahan bakar

Fitur: Nilai kalori tinggi

Aplikasi: Bahan bakar alternatif

Nilai kalori tinggi cangkang kernel sawit menjadikannya sumber bahan bakar alternatif yang sangat baik. Ini dapat digunakan di berbagai industri untuk pembangkit panas dan produksi energi.

Perbaikan tanah

Fitur: Elemen mikro yang kaya dan properti yang sedikit basa

Aplikasi: Perbaikan tanah dan remediasi tanah

Palm Kernel Shell Charcoal kaya akan elemen seperti n, P, Ca, Zn, dan MN, bermanfaat untuk peningkatan tanah. Itu dapat memperkaya tanah dengan nutrisi penting dan menyesuaikan pH, Meningkatkan kesuburan tanah dan hasil panen yang lebih baik.

Produk terkait

Membuat peralatan

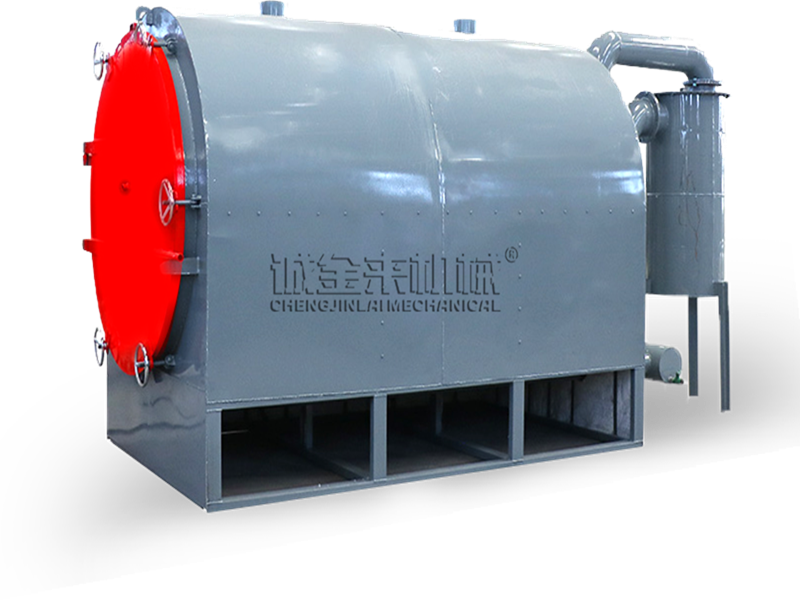

Jenis Mesin Pembuat Arang Kernel Palm

Efek karbonisasi yang lebih baik, tingkat karbonisasi yang lebih tinggi 304 bahan stainless untuk tungku dalam. Resistensi suhu tinggi.

Kandungan karbon tetap yang lebih tinggi.

Cocok untuk bahan besar seperti kayu kayu.

Struktur sederhana,mudah dioperasikan dan dipelihara dapat dikendalikan dan dapat disesuaikan

suhu karbonisasi.

Bebas asap dan bebas debu, ramah lingkungan. Mudah dioperasikan, Menghemat waktu dan tenaga. Tingkat karbonisasi yang sangat baik,tanpa menghancurkan struktur bentuk.

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177