Perkenalan: Memenuhi Permintaan Arang Shisha Premium dalam Iklim yang Menantang

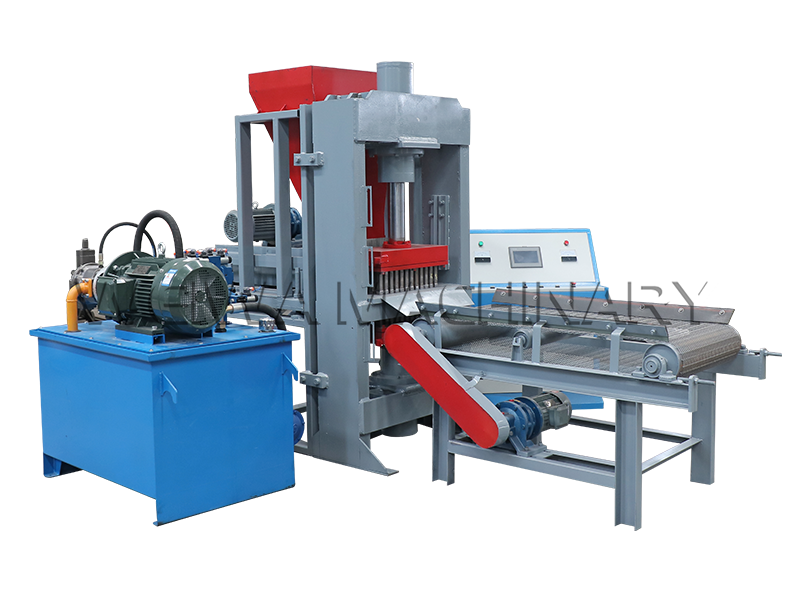

Di shisha global (pipa) industri, Kualitas briket arang secara langsung memengaruhi pengalaman pengguna. Seiring meningkatnya permintaan—terutama di wilayah yang lebih dingin seperti Rusia—produsen membutuhkan peralatan yang mampu memenuhi kebutuhankonsisten, briket kepadatan tinggiDengankinerja pembakaran yang unggul. ATMesin Weiwa, kami telah menjawab tantangan ini dengan kamiterbaru ditingkatkan mesin press hidrolik, dirancang khusus untukProduksi briket arang shisha.

Dengan30+ keahlian bertahun-tahun dalam teknologi pembuatan briket, atim purna jual profesional, dan komitmen untuksolusi khusus, Weiwa Machinery dengan bangga memperkenalkan mesin yang menggabungkanpresisi hidrolik, kemampuan beradaptasi iklim, dan daya tahan yang tak tertandingi. Di blog ini, Kami akan mengeksplorasi bagaimana mesin arang shisha hidrolik kami memecahkan tantangan produksi utama, meningkatkan kualitas briket, dan adalah sangat cocok untuk iklim Rusia.

Mengapa Mesin Press Hidrolik Mendominasi Produksi Arang Shisha

Ilmu di Balik Kompresi Hidraulik

Berbeda dengan mesin briket mekanis tradisional, mesin pers hidrolikgunakandikendalikan, sistem hidrolik bertekanan tinggiuntuk mengompres bubuk arang menjadi padat, Briket seragam. Teknologi ini menawarkan:

- Kepadatan lebih tinggi – Menghasilkan waktu pembakaran yang lebih lama dan kadar abu yang berkurang.

- Tekstur lebih halus – Meminimalkan kantong udara untuk aliran udara yang konsisten di pipa shisha.

- Konsumsi energi yang lebih rendah – Sistem hidrolik memerlukan daya yang lebih kecil dibandingkan sistem mekanis.

Untuk arang Shisha, dimanawaktu pembakaran dan konsistensi panassangat penting, pengepres hidrolik menyediakankeuntungan yang jelas.

Mengapa Perubahan Iklim di Rusia Membutuhkan Solusi Hidraulik

Rusiasuhu dingin dan fluktuasi kelembaban menimbulkan tantangan unik untuk produksi arang:

- Iklim dingindapat membuat bahan menjadi rapuh, menyebabkan keretakan pada saat kompresi.

- Kelembaban tinggimempengaruhi pengikatan material, mengurangi integritas briket.

Kamimesin press hidrolik yang ditingkatkanmengatasi masalah ini dengan:

- Sistem penyegelan yang ditingkatkanuntuk mencegah masuknya kelembapan.

- Cairan hidrolik tahan suhu untuk kinerja yang stabil dalam kondisi di bawah nol.

- Bingkai yang diperkuatuntuk menahan ekspansi dan kontraksi termal.

Ini membuat mesin Weiwapilihan ideal untuk pabrikan Rusiamencari yang dapat diandalkan, produksi berkualitas tinggi sepanjang tahun.

Fitur Utama Mesin Arang Shisha Hidraulik Weiwa yang Ditingkatkan

1. Sistem Hidraulik Presisi untuk Kepadatan Briket yang Unggul

Teknisi kami punyamengoptimalkan pengaturan tekanan hidrolikuntuk mencapai:

- Kompresi seragamdi semua briket, menghilangkan titik lemah.

- Tingkat tekanan yang dapat disesuaikanuntuk menampung bahan baku yang berbeda (MISALNYA., batok kelapa, lubang zaitun, atau arang kayu).

- Mengurangi persyaratan pengikat, menurunkan biaya produksi dengan tetap menjaga kualitas.

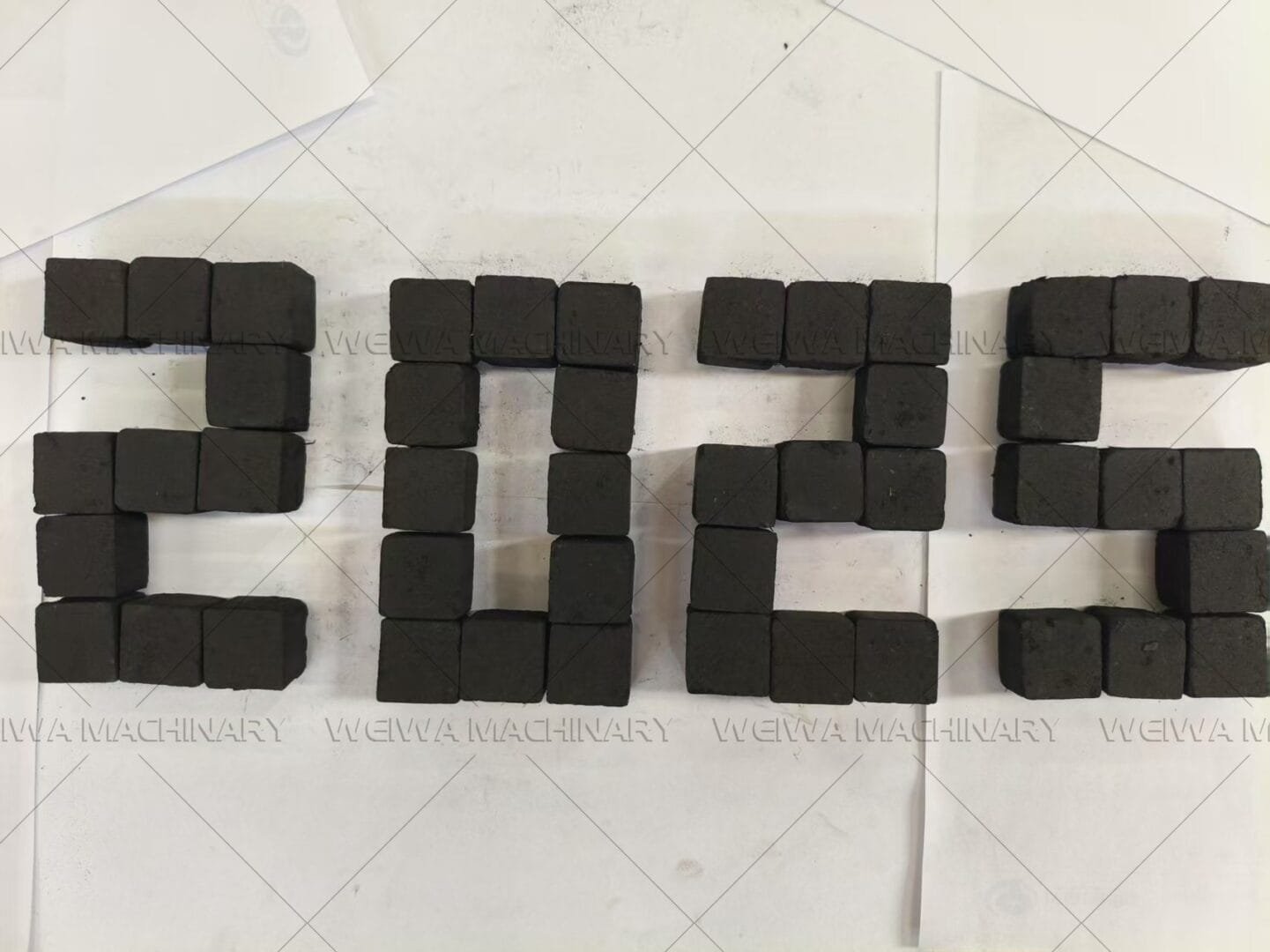

Hasilnya? Briket yang terbakar lebih lama, lebih panas, dan lebih bersih—Sempurna untuk pasar shisha premium.

2. Sistem Pendinginan Tingkat Lanjut untuk Output yang Konsisten

Sistem hidrolik menghasilkan panas selama pengoperasian, yang dapat mempengaruhi sifat material. Mesin kami meliputi:

- Sirkuit pendingin terintegrasiuntuk menjaga temperatur oli hidrolik tetap optimal.

- Pemantauan suhu otomatisuntuk mencegah panas berlebih.

Hal ini memastikankinerja yang stabil bahkan selama produksi dalam jumlah besar di musim dingin di Rusia.

3. Konstruksi Tahan Lama untuk Lingkungan yang Keras

Dibangun denganbaja bermutu tinggi dan lapisan tahan korosi, mesin kami dirancang untuk:

- Tahan suhu ekstrim (-30°C hingga +40 °C).

- Tahan karat dan keausandari kelembaban dan bahan abrasif.

- Memerlukan perawatan minimal, mengurangi waktu henti.

Daya tahan ini diterjemahkan menjadibiaya jangka panjang yang lebih rendahDanROI yang lebih tinggiuntuk klien kami.

4. Cetakan yang Dapat Disesuaikan untuk Beragam Kebutuhan Pasar

Kami memahami bahwa preferensi arang shisha berbeda-beda di setiap wilayah. Mesin kami menawarkan:

- Cetakan yang dapat dipertukarkanuntuk menghasilkan berbagai bentuk (MISALNYA., kubus, silinder, atau cakram datar).

- Ukuran briket dapat disesuaikanuntuk memenuhi kemasan tertentu atau permintaan konsumen.

Fleksibilitas ini menjadikan mesin Weiwasolusi terpadu untuk pasar global, termasuk persyaratan unik Rusia.

Aplikasi Mesin Arang Shisha Hidraulik Weiwa

1. Produksi Arang Shisha Premium

Mesin itukeluaran dengan kepadatan tinggisangat ideal untukkafe dan pengecer shisha kelas atas, di mana waktu pembakaran dan rasa sangat penting.

2. Arang Hookah untuk Pasar Ekspor

Dengan meningkatnya permintaan Rusia terhadap produk shisha impor, mesin kami memungkinkan produsen lokal untuk melakukannya:

- Menghasilkan briket yang memenuhi standar mutu internasional.

- Mengurangi ketergantungan pada impor yang mahal.

- Ketuk ke dalam $1.2 miliar pasar arang shisha global (Negarawan, 20XX).

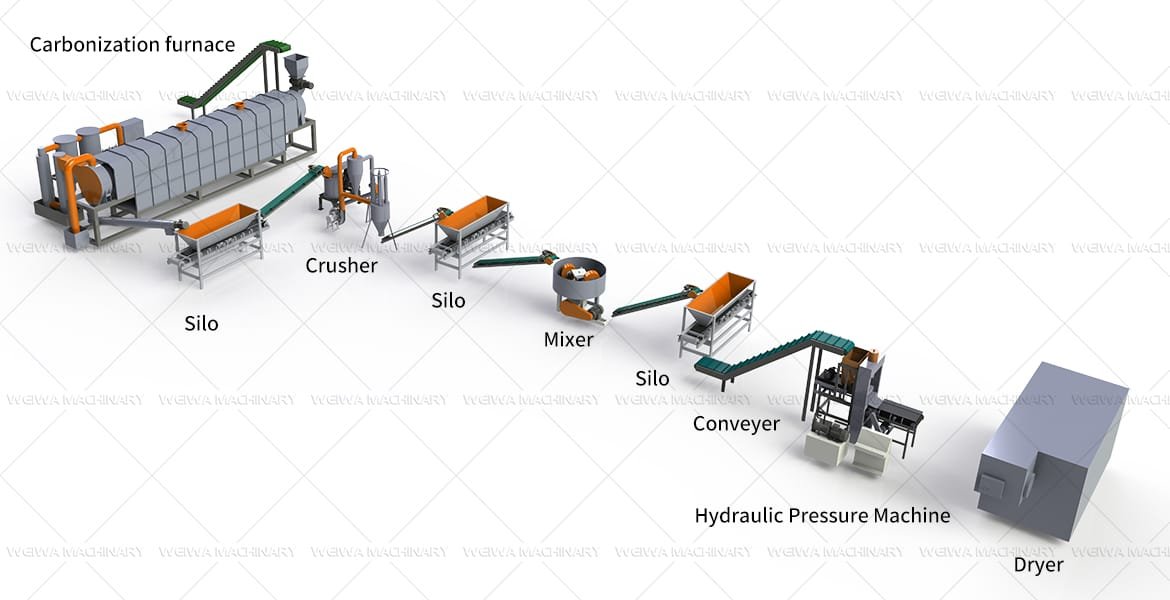

3. Pembuatan Briket Biomassa Berkelanjutan

Selain arang shisha, mesin press hidrolik kami dapat mengompreslimbah pertanian, Kerang kelapa, dan sisa kayumenjadi briket bahan bakar ramah lingkungan, mendukung dorongan Rusia untuksolusi energi terbarukan.

Mengapa Memilih Mesin Weiwa?

30+ Keunggulan Teknik Bertahun-tahun

Sejak 1990, Weiwa Machinery telah menjadi pelopor dalaminovasi peralatan briket. KamiR&Tim D terus menyempurnakan desainuntuk memenuhi kebutuhan industri yang terus berkembang, memastikan klien kami menerimateknologi mutakhir.

Dukungan dan Kustomisasi Purna Jual Profesional

Kami tidak hanya menjual mesin—kami menyediakan solusi ujung ke ujung, termasuk:

- Instalasi dan pelatihan di tempatoleh teknisi bersertifikat.

- 24/7 dukungan teknisdalam berbagai bahasa.

- Desain dan perencanaan tata letak yang disesuaikanuntuk pabrik Anda.

Baik Anda seorang pemula atau produsen mapan, tim kami akanmenyesuaikan solusisesuai kebutuhan Anda.

Jangkauan Global, Keahlian Lokal

Dengan klien di Rusia, Timur Tengah, Eropa, dan Asia, Weiwa Machinery telah membangun reputasi untukkeandalan, efisiensi, dan kepuasan pelanggan.

Kesimpulan: Tingkatkan Produksi Arang Shisha Anda dengan Mesin Press Hidrolik Weiwa

Thepeningkatan terbaru pada mesin arang Shisha hidrolik kamimenetapkan standar baru untukkualitas, daya tahan, dan kinerja. Dengan itukompresi presisi, kemampuan beradaptasi iklim, dan fitur yang dapat disesuaikan, itu adalahpilihan ideal bagi produsen yang menargetkan pasar Rusia dan global.

ATMesin Weiwa, kami berkomitmen untuk itumembantu Anda mencapai keunggulan operasional. Apakah Anda memerlukanunit skala kecil untuk pasar khususatau sebuahsistem industri besar untuk produksi massal, tim kami akanmemandu Anda di setiap langkah.

Hubungi kami hari iniuntuk sebuahkonsultasi gratis, desain khusus, atau kunjungan pabrik. Mari kita membangun sebuah lebih pintar, bisnis arang shisha yang lebih menguntungkanbersama-sama.

Telp/WhatsApp:+86 1838093177

E-mail:info@cjlmachineGroup.com

Wechat wechat

Wechat wechat