Meeting Indonesia’s Biomass Energy Needs

Dalam beberapa tahun terakhir, Indonesia has seen a growing demand for sawdust charcoal making machine lines, driven by the need for sustainable fuel alternatives and efficient biomass utilization. ATMesin Weiwa, Kami berspesialisasi dalam menyediakantungku karbonisasi horizontal that transform sawdust logs into briquettes with high efficiency.

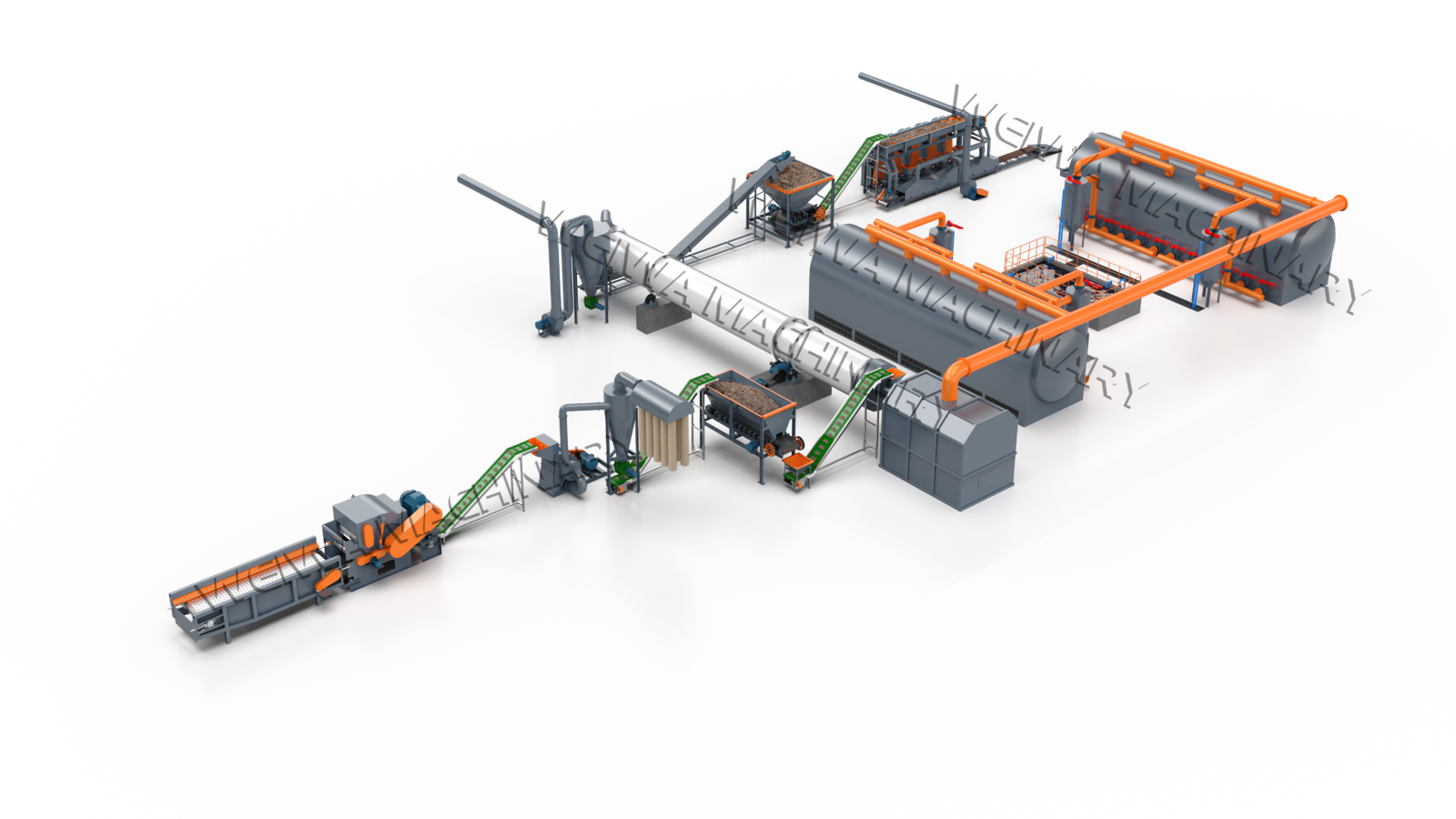

Our latest project involved designing and installing a Biomass briquette charcoal product linedi Indonesia, tailored to our client’s specific production needs.

Designing the Perfect Solution for Indonesian Customer

Understanding Client Requirements

Our Indonesian client required a high-capacity lini produksi arang serbuk gergaji. After analyzing their input materials (mainly sawdust logs) and desired output (Briket arang), our engineers developed a customized 3D design for the tungku karbonisasi horizontal.

The key considerations included:

- Optimal carbonization temperature control

- Efficient smoke emission management

- Continuous feeding and discharge system

- Energy-saving and low-maintenance operation

3D Modeling & Simulation

Before manufacturing, our engineering team created a detailed 3D model of the tungku karbonisasi horizontal, ensuring all components—such as the carbonization chamber, heating system, and conveyor belt—were perfectly aligned for smooth operation.

This digital simulation helped us:

- Minimize design flaws before production

- Ensure the furnace could handle 5 tons/hour throughput

- Optimize space and energy efficiency

On-Site Installation & Testing in Indonesia

Engineer Deployment for Machine Setup

Once the tungku karbonisasi horizontal was manufactured, our team of experienced engineers traveled to Indonesia to oversee the installation and commissioning of the entire sawdust charcoal making machine line.

The installation process included:

- Positioning the horizontal carbonization furnace in the client’s facility

- Connecting the sawdust logs machine to the carbonization unit

- Integrating the briquette pressing system for final product formation

Testing & Performance Optimization

Setelah instalasi, we conducted real-time testing to ensure the 5-ton/hour capacity was achieved while maintaining high-quality charcoal output. Key adjustments included:

- Fine-tuning temperature settings for optimal carbonization

- Ensuring smooth sawdust feeding into the furnace

- Monitoring smoke emission levels for environmental compliance

The client was impressed with the machine’s efficiency and durability, confirming that the tungku karbonisasi horizontal met their production goals.

Why Choose Weiwa Machinery’s Horizontal Carbonization Furnace?

1. Efisiensi tinggi & Kapasitas besar

Kamitungku karbonisasi horizontal is designed for Operasi Berkelanjutan, processing hingga 5 tons of sawdust per hour—making it ideal for industrial-scale charcoal production.

2. Solusi yang dapat disesuaikan

Unlike one-size-fits-all machines, Weiwa Machinery engineers each system based on client requirements, ensuring the best performance for their specific raw materials (MISALNYA., sawdust logs).

3. Operasi ramah lingkungan

Thetungku karbonisasi horizontal includes advanced smoke filtration, reducing harmful emissions and ensuring kepatuhan lingkungan.

4. Reliable After-Sales Support

Tim kami menyediakanon-site installation, pelatihan, and maintenance support to ensure smooth long-term operation—just like we did in Indonesia.

Weiwa Machinery’s Success in Indonesia

This project highlights Weiwa Machinery’s ability to deliver turnkey sawdust charcoal production solutions, dari3D design to on-site installation. Kamitungku karbonisasi horizontal proved to be a dapat diandalkan, high-capacity solution for our Indonesian client, successfully transforming sawdust logs into briquettes at a 5-ton/hour rate.

Jika Anda mencari atrusted partner in biomass carbonization, Weiwa Machinery is here to help. Contact us today to discuss your sawdust charcoal making machine line needs.

Tentang Mesin Weiwa

Mesin WeiwaAdalah produsen terkemukabiomass carbonization and briquetting equipment, berspesialisasi dalamtungku karbonisasi horizontal, sawdust logs machines, Dan complete charcoal production lines. Dengan pengalaman bertahun-tahun di bidangnyaexporting to Indonesia and other Southeast Asian markets, kami menyediakancustomized, high-efficiency solutions for turning waste biomass into valuable charcoal products.

Our commitment to kualitas, inovasi, dan dukungan pelanggan ensures that every client receives a dapat diandalkan, high-performing machine tailored to their needs.

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177