Meeting Saudi Arabia’s Growing Demand for High-Quality Charcoal Products

Dalam beberapa tahun terakhir, Saudi Arabia has seen a surge in demand for both commercial-grade charcoal (digunakan dalam metalurgi industri dan pengolahan makanan) danpremium BBQ charcoal rods (Populer di kalangan rumah tangga dan penggemar luar ruangan). Karena kerajaan terus berinvestasi dalam solusi energi berkelanjutan dan barang konsumen premium, Produsen mencari yang dapat diandalkan, high-output Mesin Pembuat Arang that can convert local biomass waste (seperti serbuk gergaji, Kerang kelapa, atau residu pertanian) menjadi padat, Produk arang yang sudah lama terbakar.

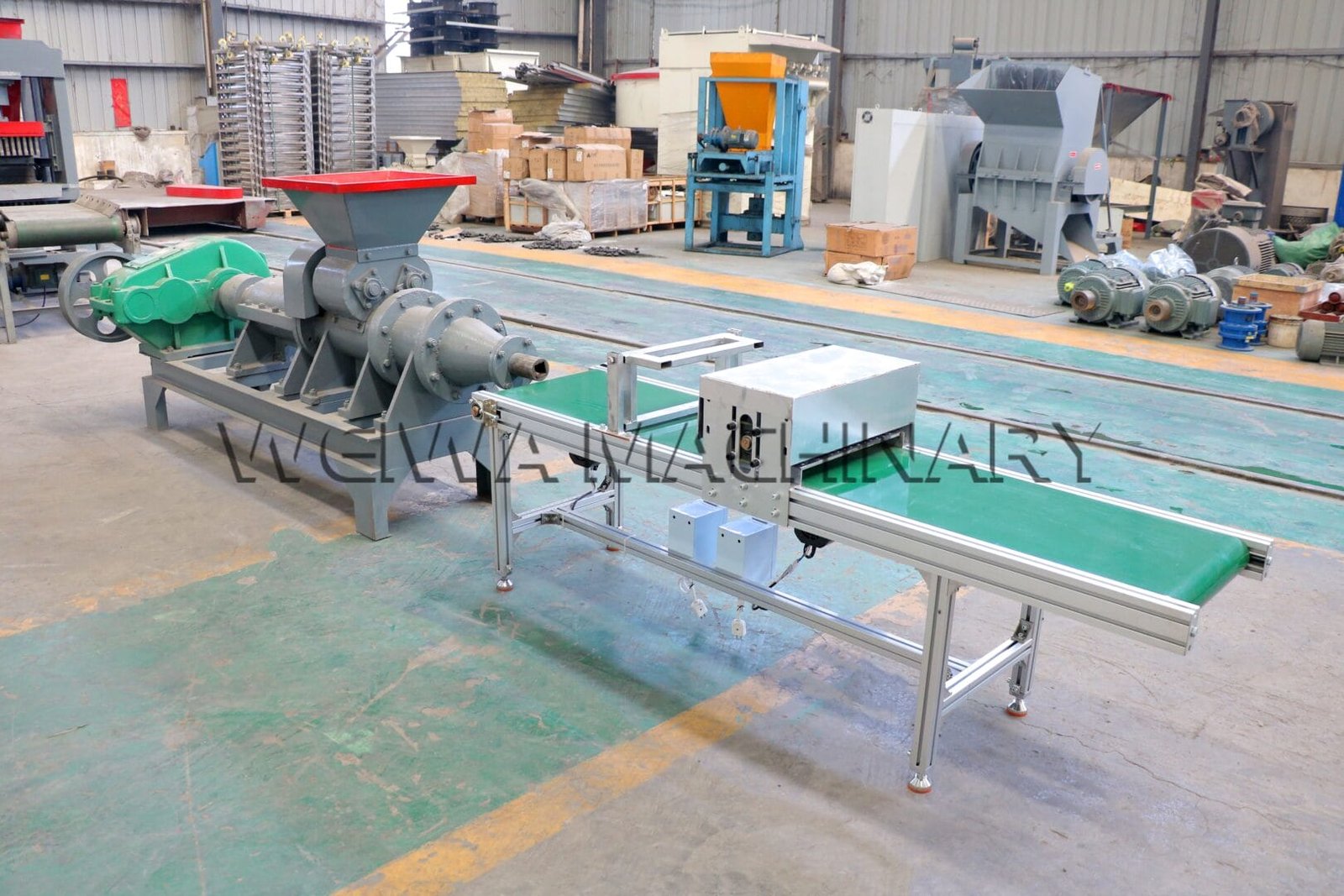

ATMesin Weiwa, we’ve been at the forefront of this shift—recently completing a successful charcoal extrude machine trial for a Saudi client.

What Is a Mesin Ekstrude Arang?

Sebelum menyelam ke hasil percobaan, Mari kita klarifikasi apaMesin Ekstrude Arang actually does. Often referred to as a charcoal rod press atau briquette extruder, this machine transforms carbonized biomass (or raw biomass mixed with a binder, depending on the feedstock) menjadi seragam, dense rods—typically 20–60mm in diameter and 30–150cm long. These rods are then carbonized further (jika diperlukan) to produce the final BBQ Charcoal atau industrial charcoal.

WeiwaMesin Ekstrude Arang is engineered with a mekanisme sekrup bertekanan tinggi that compresses the raw material evenly, eliminating air pockets and ensuring consistent density. Unlike traditional mold-based briquette machines, our extruder doesn’t rely on excessive heat or manual shaping—instead, it uses mechanical force to form rods that are stronger, more uniform, and easier to carbonize.

For Saudi clients, this is particularly important: the kingdom’s hot, dry climate demands charcoal that can withstand high temperatures without crumbling, and our extruded rods deliver just that.

The Saudi Trial Is Objectives, Pengaturan, and Key Focus Areas

Klien kami, a Saudi-based manufacturer specializing in premium BBQ charcoal and industrial fuel briquettes, approached Weiwa with two primary goals:

- Test the output consistency and durability of our charcoal rods under local biomass conditions (primarily date palm residues and sawdust).

- Evaluate the machine’s operational efficiency, ease of maintenance, and adaptability to Saudi power standards (380V/50Hz).

The trial was conducted at our factory in China (where we manufacture all equipment before export) over a 7-day period, simulating real-world production conditions. We used the client’s actual raw materials (shipped in advance) and monitored five critical metrics:

- Rod density and hardness (measured via compression testing);

- Production speed and hourly output;

- Energy consumption per ton of finished product;

- Machine stability (vibration, noise, and downtime);

- Ease of operation and maintenance requirements.

Trial Results

1. Superior Rod Quality: Dense, Uniform, and Long-Lasting

The most immediate standout was the quality of the extruded rods. Using a mix of 70% date palm fiber and 30% serbuk gergaji (a common combination in the Middle East), our machine produced rods with an average density of 1.2–1.3 g/cm³—significantly higher than the client’s previous supplier (who averaged 0.9–1.0 g/cm³).

When tested for hardness, the rods withstood over 50N of pressure without cracking (industry standard for premium BBQ charcoal is 30–40N). This means they’re less likely to break during packaging, mengangkut, or use in grills, ensuring a better customer experience. The client also noted that the rods had a smooth surface and consistent diameter, which improved their aesthetic appeal for retail packaging.

2. Efisiensi tinggi: Fast Output with Low Energy Waste

The trial achieved an average output of 800–1,000 kg of raw rods per hour (depending on raw material moisture content, which we optimized to 8–12%). For the client, this translates to approximately 300–400 kg of finished charcoal per hour after carbonization (assuming a 30–40% weight loss during the carbonization process).

Energy consumption was equally impressive: the machine used just 18–20 kWh per ton of raw rods produced, thanks to our optimized screw design and motor efficiency. Compared to older extruders that often consume 25–30 kWh/ton, this represents a 20–25% reduction in operating costs—a critical factor for Saudi manufacturers aiming to maximize profitability.

3. Reliability in Harsh Conditions: Stable Performance Under Heat and Load

Saudi Arabia’s ambient temperatures often exceed 40°C during summer, and the trial environment was intentionally set to simulate these conditions (with controlled heat in our testing facility). Despite this, the machine operated without overheating, excessive vibration, or unexpected downtime.

Key features that contributed to this stability:

- Heavy-duty steel frame with reinforced bearings to handle high torque;

- Advanced cooling system for the screw and motor, preventing thermal overload;

- Automated lubrication for moving parts, reducing friction and wear.

The client’s technician, who observed the trial, commented: “We were worried about the machine struggling with our local biomass, but Weiwa’s equipment handled everything smoothly—even at maximum capacity.”

4. User-Friendly Operation: Minimal Training Required

Another major advantage was the machine’s intuitive controls. The Saudi team, who had limited prior experience with extrude machines, were able to operate it independently after just 2 hours of training. The control panel includes:

- Digital displays for real-time monitoring of pressure, speed, and temperature;

- Adjustable screws to fine-tune rod density based on raw material type;

- Emergency stop and safety locks to prevent operator errors.

Maintenance was equally straightforward: the screw and die (the core components that shape the rods) required cleaning every 8–10 hours of operation, but no specialized tools were needed. The client noted that this “reduces downtime and labor costs significantly.”

Why Saudi Clients Choose Weiwa?

This trial isn’t an isolated success story. Over the past 3 bertahun-tahun, Weiwa has exported lebih 200 Mesin Pembuat Arang to the Middle East many of them specifically designed for BBQ rod productionDanindustrial charcoal applications.

What sets us apart?

- Customization: We tailor machine specifications (like rod diameter, kapasitas output, and power supply) to each client’s raw materials and production goals.

- Dukungan setelah penjualan: Our team provides remote guidance, on-site installation (jika diperlukan), and spare parts delivery within 72 jam.

- Rekam Jejak Terbukti: Our machines have been tested in diverse climates (from Saudi’s deserts to Uganda’s humid tropics) and consistently deliver high-quality results.

Your Partner in Efficient Charcoal Production

The success of this Saudi trial underscores what we’ve believed since founding Weiwa Machinery: the right equipment, combined with deep technical expertise, can transform biomass waste into valuable, high-demand products. Whether you’re a small-scale BBQ charcoal producer in Saudi Arabia or an industrial manufacturer in Uganda, kamiMesin Ekstrude ArangDanmesin pembuat briket batang are built to meet your needs—with proven performance, Efisiensi Energi, and reliability.

Your Trusted Partner in Charcoal Solutions

Didirikan pada 1990, Mesin Weiwa is a leading manufacturer of biomass briquette and charcoal equipment, headquartered in [Your Country/Region] with global operations spanning Indonesia (manufacturing hub), Saudi Arabia, Uganda, dan di luar. Our product line includes charcoal extrude machines, rod briquette makers, tungku karbonisasi, and complete production lines—all designed to help clients turn waste into profit.

Dengan lebih 30 pengalaman bertahun -tahun, a dedicated R&Dam D., and a commitment to customer success, we don’t just sell machines—we provide solusi ujung ke ujung tailored to your local market. Ready to start your charcoal production journey? Contact Weiwa today for a free consultation or factory tour!

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177