Why Charcoal Briquette Machines Are Booming in Laos?

Permintaan untukmesin briket arang has surged across Southeast Asia, particularly in Laos, where sustainable fuel solutions and BBQ markets are expanding. Sebagai produsen terkemuka, Mesin Weiwa recently deployed engineers to a client’s site in Laos to debug and optimize a ball charcoal briquette production line, ensuring seamless operation and high output.

Understanding Charcoal Briquette Machines

What Is a Mesin briket arang bola?

Amesin briket arang bola (juga disebut acharcoal briquette press machine) compresses charcoal dust, biomassa, or coal fines into uniform ball-shaped briquettes—ideal for grilling, Bahan Bakar Industri, or household heating. Weiwa’s machines are engineered for tekanan tinggi, daya tahan, and efficiency, ensuring minimal waste and consistent output.

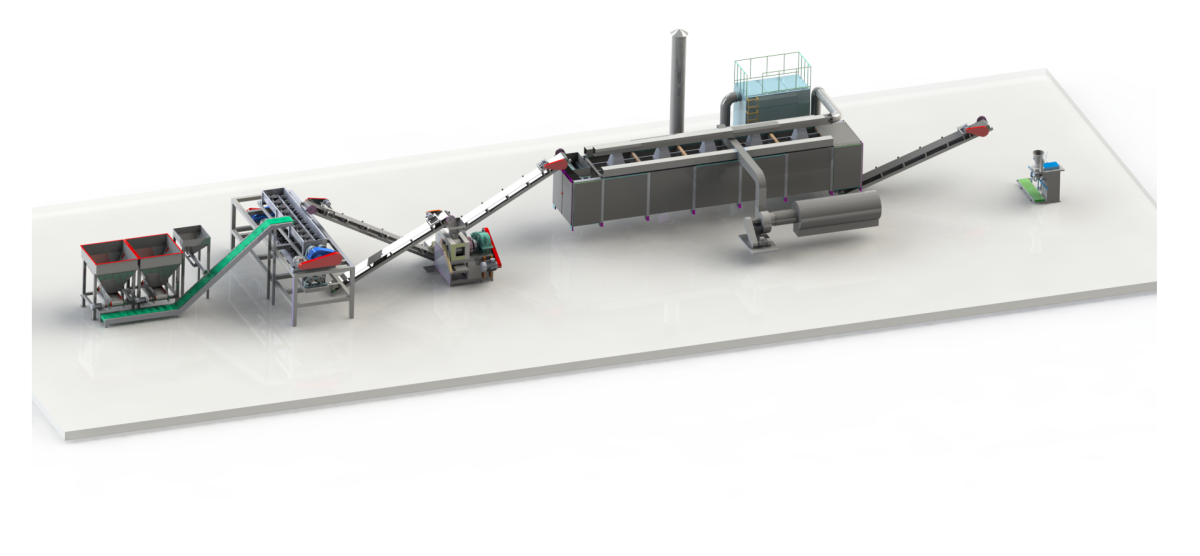

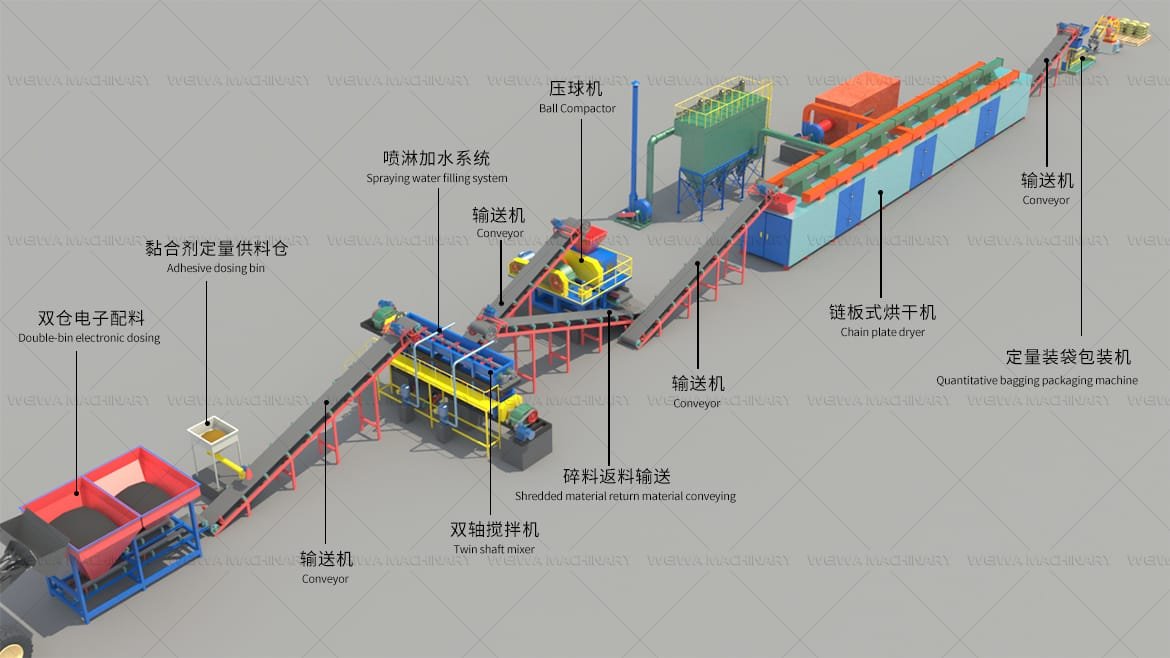

The Complete Charcoal Briquette Machine Product Line

KamiLaos client opted for an integrated briquette plant, termasuk:

- Raw material crushing & drying systems (to prepare charcoal dust)

- Mixing & binding agents (for optimal briquette formation)

- Ball charcoal briquette press machines (core pressing units)

- Drying ovens (to harden briquettes for storage & mengangkut)

Iniend-to-end production line ensures smooth workflow, reduced labor costs, and higher profitability.

On-Site Debugging in Laos

Why On-Site Support Matters?

https://youtube.com/shorts/gciDb0gWpPY?feature=share

Sementaramesin briket arang are designed for efficiency, real-world conditions—such as humidity, raw material variations, and operator skill levels—can affect performance. Weiwaengineers traveled to Laoske:

- Calibrate the briquette press for optimal pressure and shape consistency.

- Adjust the drying system based on local climate conditions.

- Train local staff on machine operation, maintenance, and troubleshooting.

Inihands-on approach ensured the client achieved maximum output with minimal downtime.

Common Debugging Issues & Solutions

- Uneven Briquette Formation → Adjusted roller gap and pressure settings.

- Drying Efficiency Problems → Modified airflow and temperature controls.

- Material Feeding Inconsistencies → Optimized conveyor speed and mixing ratios.

Thanks to Weiwa’s quick response and technical expertise, TheLaos briquette plant was fully operational within days.

Why Southeast Asia Is the Next Big Market for Charcoal Briquette Machines?

Growing Demand in Laos & Neighboring Countries

- BBQ & Restaurant Industry: Charcoal briquettes are preferred for their clean burn and long-lasting heat.

- Sustainable Fuel Alternatives: Biomass briquettes reduce reliance on wood charcoal, aligning with environmental regulations.

- Peluang Ekspor: High-quality briquettes are in demand for international markets.

Weiwasolusi khusus ensure clients in Laos and beyond can scale production efficiently.

Competitive Advantages of Weiwa’s Briquette Machines

✔High Compression Ratio → Denser, longer-burning briquettes.

✔Konsumsi energi rendah → Cost-effective operation.

✔Konstruksi yang tahan lama → Minimal wear and tear.

✔Customizable Designs → Adaptable to different raw materials.

From Consultation to After-Sales Service

Customized Planning & Desain

Every client’s needs are unique. Weiwa provides:

- Site-specific machine layouts (optimized for space & workflow).

- Detailed engineering drawings for smooth installation.

- Flexible production capacity options (kecil, sedang, or large-scale).

Tim Purna Jual Profesional

Kamidedicated support team ensures:

- Remote troubleshooting via video calls.

- On-site engineer dispatch when needed (as in Laos).

- Spare parts availability for quick replacements.

Why Choose Weiwa for Your Charcoal Briquette Machine Needs?

Weiwa Machinery has lebih 30 pengalaman bertahun -tahun in manufacturing high-performance charcoal briquette machines, with a proven track record in Laos, Asia Tenggara, and global markets. Kamiengineer-led debugging, solusi khusus, and reliable after-sales service make us the top choice for briquette production lines.

Need a ball charcoal briquette machine for your business?

Contact Weiwa Machinery today for a free consultation, design plans, and a competitive quote!

- Massa:+8613838093177

- Whatsapp:+8613838093177

- E-mail:info@cjlmachineGroup.com

Tentang Mesin Weiwa

Dengan30+ keahlian bertahun -tahun, Mesin Weiwa specializes in customized charcoal briquette machines, ball press machines, and complete production lines. Kamitim purna jual profesional, on-site engineering support, dandesign & planning services ensure seamless operations for clients worldwide. Apakah Anda memerlukansmall-scale briquette press or a full production plant, Weiwa is your trusted partner.

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177