Perkenalan

Di dunia yang sadar lingkungan saat ini, Bisnis dan industri terus mencari cara berkelanjutan untuk mengelola limbah dan mengoptimalkan produksi bahan bakar. Itu Pers briket hidrolik menonjol sebagai mesin revolusioner yang mengubah limbah biomassa menjadi kepadatan tinggi, Briket hemat energi. Apakah Anda berada di daur ulang, pertanian, atau sektor energi, Berinvestasi dalam pers briket hidrolik dapat secara signifikan meningkatkan produktivitas dan profitabilitas.

Apa itu pers briket hidrolik?

A Pers briket hidrolik adalah canggih mesin briket yang menggunakan sistem hidrolik tekanan tinggi untuk mengompres bahan baku (seperti serbuk gergaji, limbah pertanian, bubuk arang, atau chip logam) menjadi kompak, Briket seragam. Tidak seperti mesin cetak mekanis, Model hidrolik menawarkan kontrol tekanan yang unggul, memastikan kepadatan yang lebih tinggi dan efisiensi pembakaran yang lebih baik.

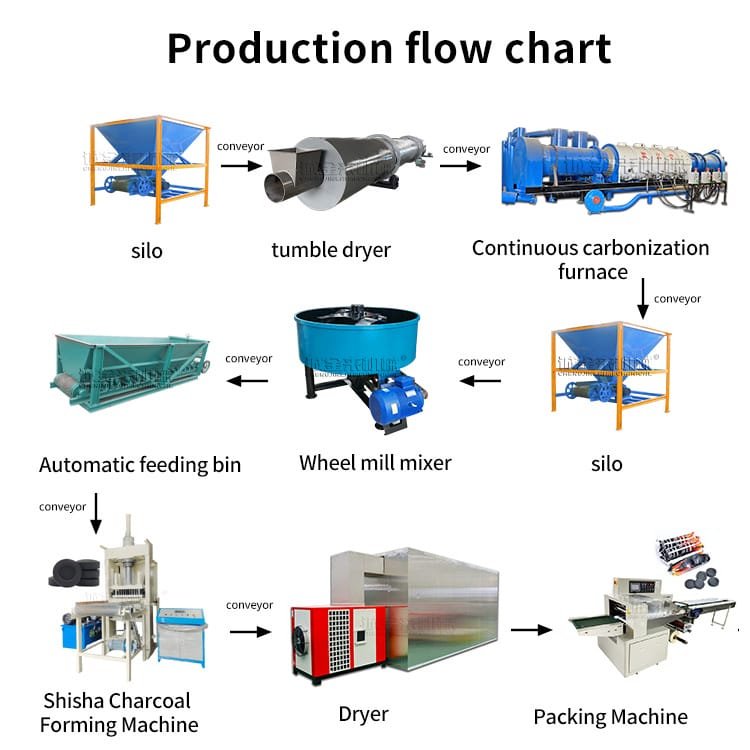

Bagaimana cara kerjanya?

-

Pemberian makan material - Biomassa mentah dimasukkan ke dalam hopper mesin.

-

Kompresi - Silinder hidrolik memberikan tekanan ekstrem (hingga 3000 psi atau lebih), memadatkan bahan.

-

Briket ejeksi - Briket yang terbentuk diekstrusi dalam bentuk yang konsisten (berbentuk silinder, heksagonal, atau cetakan khusus).

-

Pendinginan & Kemasan - Briketnya dingin dan mengeras sebelum dikemas untuk penyimpanan atau penjualan.

Mengapa Memilih Pers Briket Hidrolik daripada Mesin Lain?

| Fitur | Pers hidrolik | Tekan sekrup | Pers mekanis |

|---|---|---|---|

| Kontrol tekanan | Tinggi & bisa disesuaikan | Terbatas | Sedang |

| Kepadatan briket | Sangat tinggi | Sedang | Sedang |

| Efisiensi Energi | Dioptimalkan | Konsumsi tinggi | Sedang |

| Pemeliharaan | Rendah | Tinggi (keausan sekrup) | Sedang |

| Tingkat kebisingan | Rendah | Tinggi | Sedang |

Keuntungan utama:

Kepadatan briket yang lebih tinggi - Waktu terbakar yang lebih lama, efisiensi bahan bakar yang lebih baik.

Biaya operasi yang lebih rendah - Sistem hidrolik mengkonsumsi daya yang lebih sedikit dari pada tekan sekrup.

Penggunaan materi yang serba guna - Bekerja dengan serbuk gergaji, sekam padi, arang, sisa logam, dan lebih banyak lagi.

Daya tahan & Pemeliharaan rendah - lebih sedikit bagian yang bergerak mengurangi keausan.

Ramah lingkungan - Mengubah limbah menjadi bahan bakar yang berharga, Mengurangi penggunaan TPA.

Siapa yang bisa mendapat manfaat dari pers briket hidrolik?

1. Arang & Produsen biomassa

Putar serbuk gergaji, Kerang kelapa, atau keripik kayu ke briket arang premium untuk dipanggang, pemanas, dan penggunaan industri.

2. Pertanian & Kehutanan

Repurpose limbah tanaman (sekam padi, jerami, Bestasse) menjadi briket bahan bakar yang dapat dijual.

3. Tanaman daur ulang logam

Serutan logam kompak (aluminium, besi) untuk transportasi dan peleburan yang lebih mudah.

4. Perusahaan pengelolaan limbah

Kurangi limbah TPA dengan mengubah residu organik menjadi briket yang menguntungkan.

5. Tanaman boiler industri

Gunakan briket dengan kepadatan tinggi sebagai alternatif yang hemat biaya untuk batubara atau kayu bakar.

Memaksimalkan ROI dengan pers briket hidrolik

Berinvestasi dalam pers briket hidrolik berkualitas tinggi dapat menghasilkan pengembalian cepat melalui:

-

Menjual briket ke pasar lokal, Restoran, atau industri.

-

Mengurangi biaya pembuangan limbah dengan menggunakan kembali biomassa.

-

Menurunkan biaya energi dengan menggunakan briket yang diproduksi sendiri untuk pemanasan.

Untuk tipnya: Pasangkan pers Anda dengan a tungku karbonisasi untuk menghasilkan briket arang bernilai tinggi!

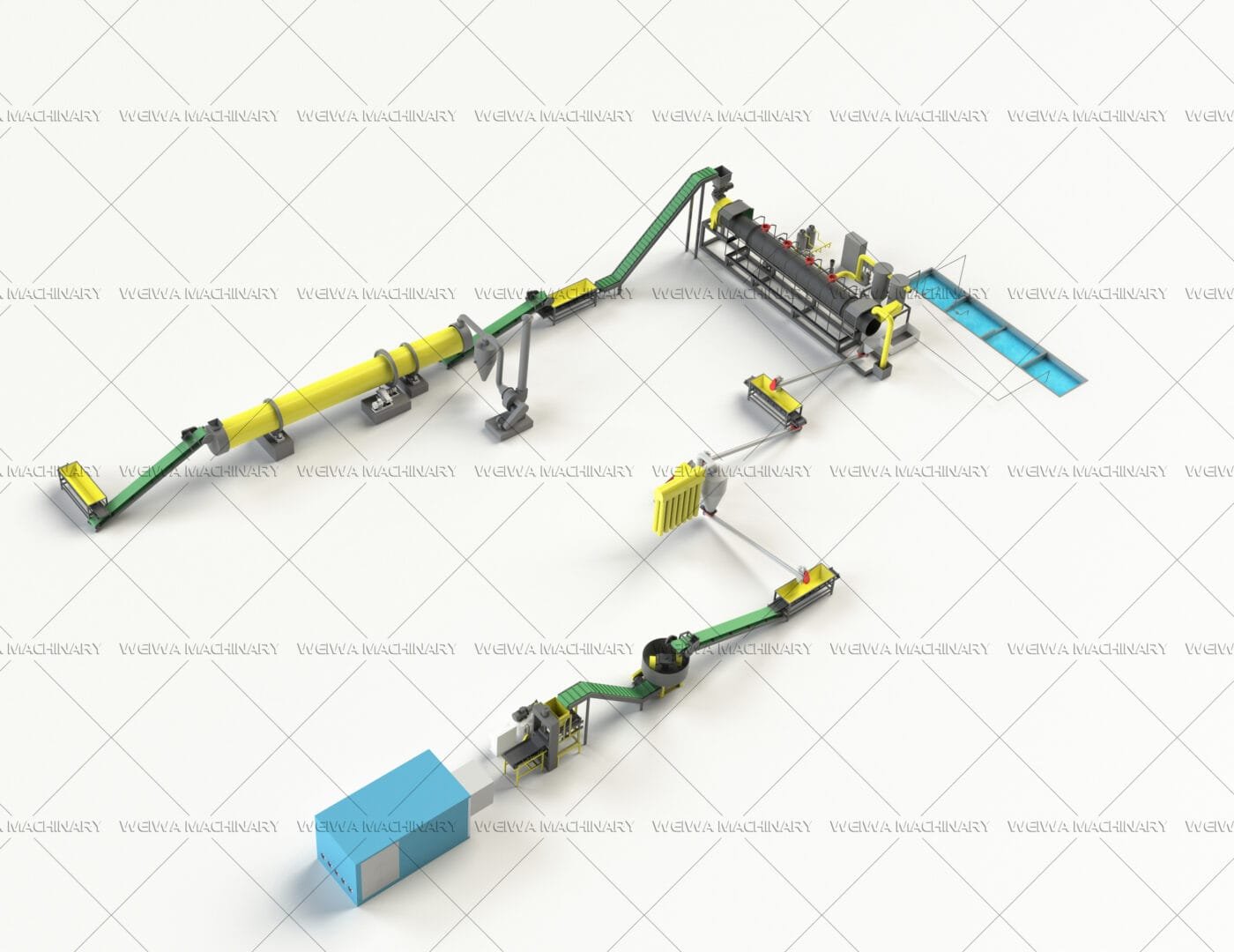

Insinyur kami juga bisa Rancang gambar dan rencanakan situs untuk Anda berdasarkan kebutuhan Anda dan kondisi situs.

Kesimpulan: Adalah tekan briket hidrolik tepat untuk Anda?

Jika Anda mencari efisien, pemeliharaan rendah, dan menguntungkan cara memproses biomassa atau limbah logam, A Pers briket hidrolik adalah solusi yang ideal. Dengan teknologi kompresi yang unggul dan penghematan biaya jangka panjang, Ini adalah investasi cerdas untuk bisnis yang berkelanjutan.

Siap Meningkatkan Produksi Anda? Hubungi kami hari ini untuk menemukan pers briket yang sempurna untuk kebutuhan Anda!

Hubungi kami

Hubungi sekarang: +8613838093177

Email kami: info@cjlmachineGroup.com

Ingin konsultasi gratis? Biarkan para ahli kami membantu Anda memilih mesin terbaik untuk efisiensi maksimal!

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177