Introduction to Charcoal Briquette Machines

Charcoal briquette machines, seperti charcoal extruders, sangat penting untuk mengubah biomassa limbah atau debu batu bara menjadi batang bahan bakar dengan kepadatan tinggi. Mesin-mesin ini banyak digunakan di Uganda untuk aplikasi domestik dan industri karena efektivitas biaya dan manfaat lingkungannya.

ATMesin Weiwa, we specialize in manufacturing high-performance charcoal extruder machines, mesin ekstruder serbuk gergaji, Dan mesin briket bola designed for efficiency and durability. Di blog ini, we’ll explore the working principles of these machines and share insights from a recent test run of our equipment.

How Does a Charcoal Extruder Machine Work?

Key Components & Proses

AMesin Ekstruder Arang compresses raw materials (bubuk arang, Debu Batubara, atau biomassa) di bawah tekanan tinggi, forcing them through a mold to form solid briquettes. Prosesnya melibatkan:

- Sistem makan: Raw materials are fed into the machine’s hopper.

- Kompresi & Ekstrusi: A screw conveyor pushes the material into a compression chamber, where high pressure forms dense rods.

- Pemotongan & Pengeringan: The extruded rods are cut to size and dried for optimal combustion.

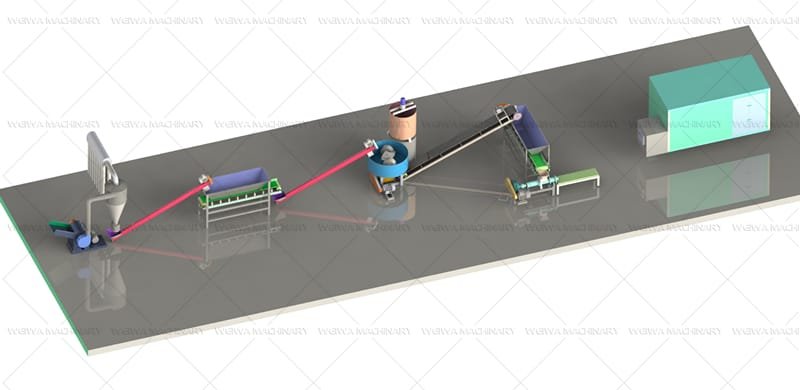

We can also customize the Jalur produksi according to the customers’ persyaratan.

Why Choose a Rod Briquette Machine?

Rod-shaped briquettes offer several advantages:

- Kepadatan lebih tinggi for longer burning time.

- Lower smoke emissions compared to loose charcoal.

- Easier storage & angkutan due to uniform shape.

Weiwa’s Charcoal Extruder Test Run: Key Findings

Test Setup & Parameters

We conducted a real-world test run of our Mesin Ekstruder Arang under typical Ugandan operating conditions. The test focused on:

- Production capacity (kg/hour)

- Energy efficiency (power consumption)

- Briquette quality (kepadatan, daya tahan, dan membakar waktu)

Performance Results

Our machine demonstrated:

- High output efficiency, producing 500-1000 kg/hour depending on material moisture.

- Low power consumption, making it cost-effective for small and medium businesses.

- Consistent briquette quality, with dense, crack-free rods ideal for cooking and industrial use.

Factors Affecting Charcoal Extruder Machine Price in Uganda

When evaluating charcoal making machine prices, consider:

- Machine capacity (small-scale vs. industrial models).

- Material compatibility (Debu arang, serbuk gergaji, atau limbah pertanian).

- After-sales support, including installation and maintenance.

Weiwa Machinery offers competitive pricingTanpa mengorbankan kualitas, ensuring a strong return on investment for Ugandan customers.

Mengapa Memilih Mesin Weiwa?

Denganlebih 30 pengalaman bertahun -tahun, Weiwa Machinery is a trusted name in briquette machine manufacturing. Kamiexpert technical team provides:

- Solusi khusus tailored to your production needs.

- Instalasi di tempat & pelatihan for smooth operation.

- Reliable after-sales support, including spare parts and troubleshooting.

Apakah Anda memerlukanMesin Ekstruder Arang, rod briquette press, atau full production line, Weiwa delivers tahan lama, high-performance equipment at a fair price.

Hubungi kami

WhatsApp/WeChat/Tel:+86 13838093177

E-mail:info@cjlmachineGroup.com

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177