Permintaan global untuk solusi berkelanjutan sedang meroket. Biochar, stabil, Bentuk arang yang kaya karbon yang dihasilkan dari biomassa, berada di garis depan revolusi ini. Ini bukan hanya amandemen tanah yang sangat baik meningkatkan kesuburan dan hasil panen; Ini adalah alat yang ampuh untuk sekuestrasi karbon dan pengelolaan limbah. Untuk bisnis dan pengusaha yang ingin memanfaatkan emas hijau ini, Berinvestasi di sebelah kananPeralatan Produksi BiocharAdalah langkah pertama yang kritis.

Pada Mesin Weiwa, Kami memahami bahwa menavigasi dunia mesin biochar, Kilns, dan teknologi terkait bisa rumit. Panduan ini demistifkan produksi biochar modern, Menyoroti teknologi utama dan bagaimana solusi inovatif Weiwa dapat membantu Anda mencapai efisiensi, profitabilitas, dan dampak lingkungan.

Apa itu Biochar & Mengapa itu penting?

Biochar diproduksi melaluipirolisis: Pemanasan biomassa organik (seperti keripik kayu, sekam padi, Kerang kelapa, residu pertanian, atau bahkan jenis limbah tertentu) dalam lingkungan oksigen rendah. Proses ini menguraikan materi tanpa pembakaran penuh, Mengunci karbon menjadi bentuk padat yang stabil alih -alih melepaskannya sebagai CO2.

Manfaatnya

- Supercharger tanah:Meningkatkan retensi air, Ketersediaan nutrisi, dan aktivitas mikroba, mengarah ke tanaman yang lebih sehat dan berkurangnya kebutuhan pupuk.

- Gudang karbon:Penggabungan karbon selama berabad -abad atau ribuan tahun, menjadikannya alat vital dalam memerangi perubahan iklim. nyatanya, Penghapusan karbon biochar terwakili 90% kredit karbon yang disampaikan 2023, menyoroti dampaknya yang diakui.

- Transformator limbah:Menyediakan outlet yang berharga untuk pertanian, kehutanan, dan limbah organik lainnya, Mengurangi biaya pembuangan dan beban lingkungan.

- Aliran pendapatan:Biochar yang diproduksi, bersama dengan produk sampingan yang berharga seperti Syngas (dapat digunakan untuk proses panas) dan cuka kayu (Pestisida/pupuk alami), menciptakan potensi pendapatan yang signifikan. Pasar Biochar Global diproyeksikan akan tumbuh secara signifikan, didorong oleh tuntutan keberlanjutan.

Bagaimana peralatan produksi biochar modern bekerja

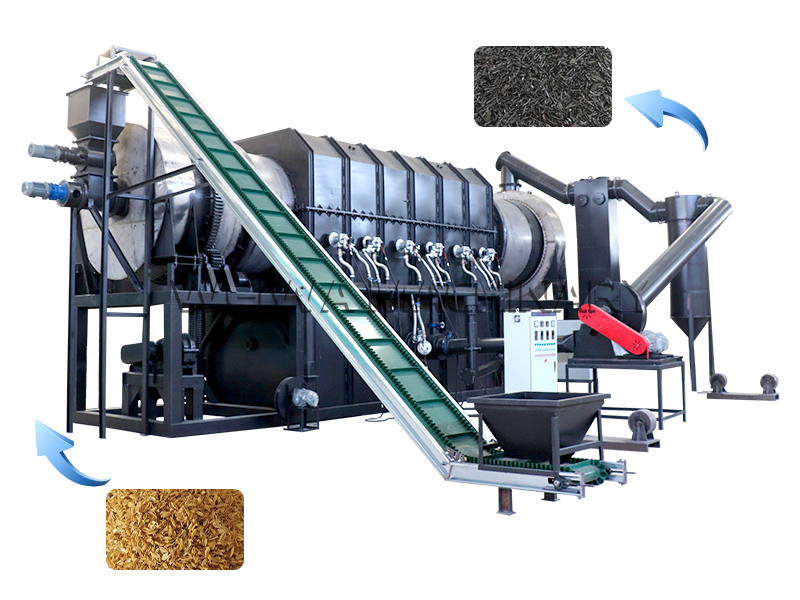

Lewatlah sudah hari -hari yang tidak efisien, mencemari metode tradisional. Modernmesin biocharTeknologi berfokus pada operasi berkelanjutan, Efisiensi Energi, kepatuhan lingkungan, dan output berkualitas tinggi. Inilah rincian proses inti:

- Persiapan bahan baku:Biomassa mentah (kayu, bambu, KULUT NAS, batok kelapa, jerami, Palm Kernel Shell, dll.) dikeringkan (Idealnya untuk <20% kelembaban) dan sering robek atau terkelupas untuk pemrosesan yang seragam.

- Proses karbonisasi (Hati):Biomassa yang disiapkan memasukiKiln BiocharAtau reaktor. Di lingkungan terbatas oksigen, itu dipanaskan hingga suhu tinggi (biasanya 400-800 ° C.). Proses pirolisis ini mengusir gas dan kelembaban yang mudah menguap, Meninggalkan Struktur Karbon Padat - Biochar.

- Teknologi Utama:Sistem Modern, Seperti Weiwa yang majuTungku karbonisasi berkelanjutan, Izinkan pemberian makan dan pelepasan tanpa henti. Ini secara drastis meningkatkan efisiensi dan output dibandingkan dengan sistem batch yang lebih lama.

- Pemulihan produk sampingan & Pemanfaatan:Gas yang mudah terbakar (Syngas) dilepaskan selama pirolisis tidak terbuang. Mereka ditangkap, dimurnikan (MISALNYA., Menghapus senyawa tar dan belerang), dan biasanya didaur ulang untuk bahan bakar tungku itu sendiri, menciptakan sangat hemat energi, sistem loop tertutup. Kelebihan syngas terkadang dapat digunakan untuk kebutuhan energi lainnya. Cairan kental dikumpulkan sebagai cuka kayu.

- Koleksi Biochar & Pengolahan:Biochar yang didinginkan dikeluarkan, siap digunakan atau pemrosesan lebih lanjut (seperti menghancurkan, penyaringan, atau peleting menggunakan aBriket mesinUntuk aplikasi pasar tertentu).

Keuntungan mesin Weiwa

- Karbonisasi kontinu cutting-edge:Teknologi andalan kami, TheTungku karbonisasi berkelanjutan, memastikan throughput maksimum dengan downtime minimal, secara signifikan meningkatkan kapasitas produksi dan ROI Anda.

- Efisiensi bahan bakar yang tak tertandingi:Dengan mendaur ulang pirolisis syngas secara cerdas untuk memberi daya pada proses, Sistem kami secara drastis mengurangi atau bahkan menghilangkan kebutuhan akan sumber bahan bakar eksternal, memangkas biaya operasional.

- Patuh lingkungan:Kami mengintegrasikan sistem kontrol emisi canggih (seperti semprotan dedustasi dan kondensasi) untuk memastikan operasi yang bersih dan memenuhi standar lingkungan, mengubah pengelolaan limbah menjadi aset lingkungan.

- Fleksibilitas untuk Bahan Baku Beragam:Apakah Anda memprosesKerang kelapa (Mesin Pembuat Arang Kelapa), serbuk gergaji (Mesin pembuat arang serbuk gergaji), sekam padi, jerami (Mesin pembuat arang jerami), bambu (Mesin pembuat arang bambu), atau cangkang kernel palem, Sistem Weiwa direkayasa untuk hasil yang optimal.

- Output biochar berkualitas tinggi:Kontrol suhu yang tepat dan desain reaktor yang dioptimalkan memastikan konsisten, Biochar bermutu tinggi dengan sifat yang sangat baik untuk amandemen tanah atau aplikasi lainnya.

- Skalabilitas:Dari pengaturan yang lebih kecil keBiochar skala besar membuat peralatan produksi, Kami memberikan solusi yang disesuaikan dengan persyaratan volume spesifik dan tingkat investasi Anda.

Di luar tanah: Pasar yang berkembang untuk Biochar

Sedangkan peningkatan tanah tetap menjadi pasar utama, Potensi biochar berkembang pesat, membuka aliran pendapatan baru:

- Aditif pakan ternak:Meningkatkan pencernaan dan mengurangi emisi pada ternak.

- Bahan konstruksi:Meningkatkan sifat beton atau komposit.

- Penyaringan air:Menghapus kontaminan secara efektif.

- Kredit karbon:Menghasilkan kredit penghapusan karbon terverifikasi yang dijual di pasar sukarela. Dengan penghilangan karbon biochar menjadi sangat hemat biaya (~27/ton), Ini adalah pendorong keuangan utama.

- Proses industri:Sebagai agen pereduksi atau bahan pengisi.

Berinvestasi dalam serbagunaPeralatan Produksi BiocharMemposisikan Anda untuk memanfaatkan pasar yang beragam dan berkembang ini.

Memilih Mesin Biochar Anda: Pertimbangan utama

- Jenis bahan baku & Volume:Biomassa apa yang akan Anda proses terutama? Apa volume harian/mingguan Anda?

- Kapasitas output yang diinginkan:Berapa banyak biochar yang perlu Anda hasilkan per hari/bulan?

- Level Otomasi:Apakah Anda memerlukan sistem yang sepenuhnya berkelanjutan (Tungku karbonisasi berkelanjutan) atau merupakan solusi semi-otomatis yang cukup?

- Sumber energi & Efisiensi:Memprioritaskan sistem memaksimalkan resirkulasi syngas untuk meminimalkan biaya bahan bakar.

- Peraturan lingkungan:Pastikan peralatan termasuk fitur kontrol emisi yang diperlukan.

- Ruang angkasa & Infrastruktur:Pertimbangkan persyaratan jejak dan utilitas (kekuatan, air).

- Anggaran & ROI:Menyeimbangkan investasi awal dengan penghematan operasional jangka panjang dan potensi pendapatan.

Mengapa Bermitra dengan Mesin Weiwa?

Weiwa Machinery adalah inovator dan produsen terkemuka dalam pemrosesan biomassa danperalatan karbonisasiSektor. Kami menggabungkan keahlian rekayasa mendalam dengan komitmen terhadap keberlanjutan dan keberhasilan pelanggan. Misi kami adalah memberikan yang kuat, efisien, dan solusi hemat biaya yang memberdayakan bisnis untuk mengubah aliran limbah menjadi sumber daya yang berharga dan berkontribusi secara bermakna pada ekonomi melingkar.

Kami tidak hanya menjual mesin; Kami bermitra dengan Anda untuk sukses. Dari konsultasi awal dan penilaian kelayakan hingga desain peralatan yang disesuaikan, Dukungan Instalasi, dan layanan purna jual, Tim kami berdedikasi untuk memastikan usaha produksi biochar Anda berkembang pesat.

Hubungi mesin Weiwa hari ini!

Biarkan para ahli kami membantu Anda merancang lini produksi biochar yang sempurna yang disesuaikan dengan kebutuhan dan tujuan spesifik Anda. Permintaan Penawaran, Jadwalkan konsultasi, atau mintalah lebih banyak informasi teknis.

- Kunjungi halaman produk kami:Jelajahi jangkauan kamiPeralatan karbonisasi.

- Hubungi:Email kami di info@cjlmachineGroup.com atau hubungi 8613838093177 untuk berbicara dengan spesialis.

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177