Perkenalan: The Rising Demand for Hookah Charcoal

Dalam beberapa tahun terakhir, Theglobal demand for hookah (Shisha) arang has surged, Didorong oleh semakin populernya perokok air di Timur Tengah, Eropa, and North America. Unlike traditional wood-based charcoal, hookah charcoal requires high density, long burn time, and minimal smoke, membuatcoal-based briquettes an increasingly viable alternative.

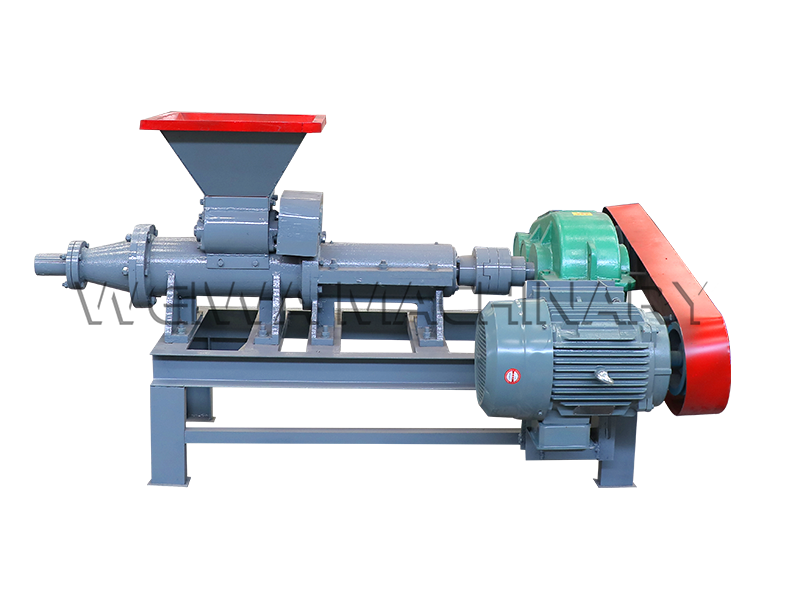

ATMesin Weiwa, we have upgraded our mesin batang batubara (charcoal extruder) to produce high-quality hookah charcoal at a lower production cost, leveraging binder-free or low-binder formulations for a cleaner burn.

Understanding the Charcoal Extruder Machine: Cara kerjanya

What is a Coal Rod Machine (Charcoal Extruder)?

Amesin batang batubara, also known as a charcoal extruder or charcoal briquette machine, is a mechanical device that compresses powdered or granulated charcoal into dense rods or sticks using high pressure and sometimes binders.

Kamiupgraded coal rod machine is designed to:

- Produce uniform, high-density charcoal rods (ideal for hookah use).

- Operate efficiently with lower energy consumption.

- Use cost-effective raw materials (including coal fines, biomassa, or blends).

- Minimize waste and maximize output.

Why a Coal Rod Machine is Ideal for Hookah Charcoal?

Hookah charcoal requires:

✔High density (for longer burn time)

✔Asap rendah & abu (for a smoother smoking experience)

✔Consistent shape & ukuran (for even heating)

Kamicoal extruder machine achieves this by compressing charcoal powder into tightly bound rods, which can then be carbonized or directly used depending on the formulation.

Why Our Upgraded Coal Rod Machine is a Game-Changer

1. Lower Production Costs with Affordable Raw Materials

Traditional hookah charcoal is often made from coconut shells or hardwood, which are expensive and limited in supply. Kamicoal rod machine allows the use of cheaper coal fines or biomass blends, reducing raw material costs by up to 40%.

2. Higher Efficiency & Konsistensi

Kaminewly optimized extruder ensures:

- Uniform rod density (no cracking or breaking).

- Adjustable pressure settings for different charcoal types.

- Faster production rates with minimal downtime.

3. Ramah lingkungan & Binder-Free Options

Unlike some charcoal briquette machines that rely on chemical binders, kamicoal rod machine can produce binder-free or low-binder hookah charcoal, making it cleaner and more environmentally friendly.

4. Versatility in Production

While our machine is optimized for Hookah Charcoal, it can also produce:

- BBQ charcoal briquettes

- Industrial carbon rods

- Biomass fuel sticks

Iniversatility makes it a smart investment for businesses looking to diversify their product lines.

The Science Behind Hookah Charcoal Production Using a Coal Rod Machine

How Coal-Based Hookah Charcoal is Made

- Persiapan Bahan Baku – Coal fines, pati (optional binder), and additives are mixed.

- Ekstrusi – The coal rod machine compresses the mixture into dense rods.

- Pengeringan – The rods are dried to remove moisture.

- Karbonisasi (Opsional) – For a purer burn, the rods can be carbonized in a kiln.

Why Coal-Based Hookah Charcoal is Gaining Popularity

- Waktu terbakar lebih lama (compared to quick-lighting charcoal).

- No chemical additives (when using natural binders).

- Cost-effective for manufacturers.

Kamiupgraded coal briquette machine ensures that these benefits are maximized while keeping production efficient and affordable.

Potensi pasar: Why Invest in Coal Rod Machine for Hookah Charcoal?

1. Growing Global Demand

- Theglobal hookah market is expected to reach $5 miliar oleh 2030.

- Middle Eastern and European markets prefer high-quality, long-burning charcoal.

2. Competitive Advantage with Lower Costs

By using coal instead of coconut shells, manufacturers can reduce production costs while maintaining quality.

3. Sustainable & Scalable Production

Kamicoal extruder machine allows for scalable production, whether you’re a small business or a large-scale manufacturer.

Kesimpulan: Why Weiwa Machinery is Your Best Partner for Hookah Charcoal Production

ATMesin Weiwa, we have lebih 30 pengalaman bertahun -tahun in manufacturing Mesin Pembuat Arang, termasukcoal rod machines, charcoal extruders, and briquette presses. Kaminewly upgraded coal rod machine is designed to maximize efficiency, mengurangi biaya, and produce high-quality hookah charcoal.

What We Offer:

Dukungan Purna Jual Profesional – Our team ensures smooth operation.

Solusi khusus- Kami mendesainmesin yang disesuaikanberdasarkan kebutuhan Anda.

Site Planning & Blueprint Services – We help optimize your production layout.

Layanan OEM/ODM – We can customize machines for your brand.

Tentang mesin Weiwa

Denganlebih 30 keahlian bertahun -tahun in the machinery industry, Mesin Weiwa specializes in charcoal production equipment, termasukcoal rod machines, charcoal extruders, and briquette presses. Kamitim purna jual profesional, customized design services, danon-site planning support ensure that every client gets the best solution for their needs.

Custom Machinery Design

Expert Technical Support

Global Shipping & Installation

Hubungi kami hari iniUntuk mendapatkan afree quote or consultation for your charcoal production line.

- Massa:+8613838093177

- Whatsapp:+8613838093177

- E-mail:info@cjlmachineGroup.com

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177