Perkenalan: Meeting Zimbabwe’s Charcoal Demand

Afrika, khususnya Zimbabwe, faces a growing need for eco-friendly fuel alternatives like sawdust charcoal briquettes. Traditional charcoal production depletes forests, while sawdust-based charcoal offers a renewable solution. ATMesin Weiwa, kami baru-baru ini melakukansuccessful sawdust extruder and charcoal briquette machine trial for a Zimbabwean client, demonstrating our equipment’s efficiency in transforming waste sawdust into high-quality charcoal.

Why Sawdust Charcoal? The African Context

The Challenge of Traditional Charcoal in Zimbabwe

Zimbabwe, Seperti banyak negara Afrika, relies heavily on wood-derived charcoal for cooking and heating. Namun, this practice leads to deforestation, soil erosion, and carbon emissions. The government and environmentalists are pushing for sustainable alternatives, dansawdust charcoal briquettes are emerging as a viable solution.

How Sawdust Charcoal Helps

- Pemanfaatan limbah: Sawdust from woodworking industries is usually discarded, but it can be compressed into briket kepadatan tinggi.

- Cleaner Burning: Sawdust charcoal produces less smoke and more heat than traditional charcoal.

- Economic Opportunity: Local entrepreneurs can profit from waste while meeting fuel demands sustainably.

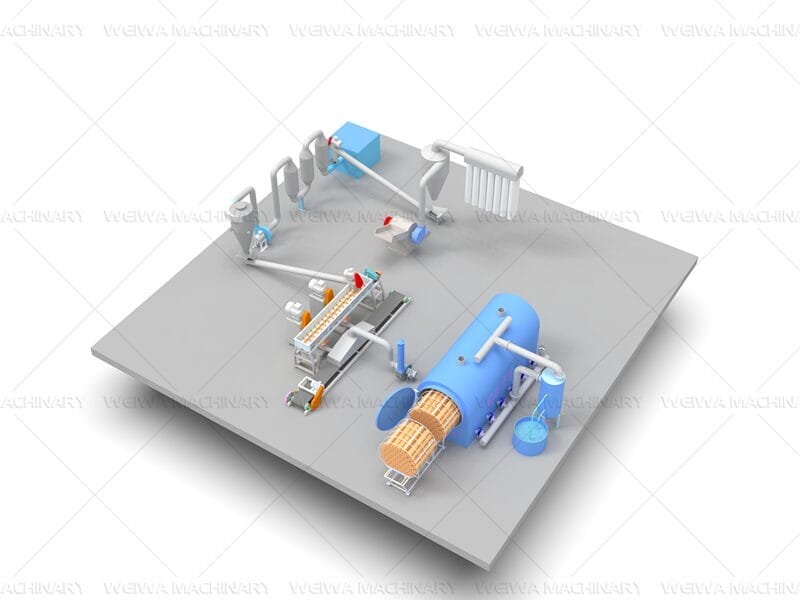

Weiwa’s Sawdust Charcoal Production Line: Key Machines

Kamisawdust-to-charcoal production line for Zimbabwe includes:

1. Extruder serbuk gergaji (Sawduat Extrude Production Line)

Theekstruder serbuk gergaji compresses sawdust into padat, cylindrical blocks (called “Briket” atau “log”) without binders. Our extruder in the trial diproses 1-1.5 tons of sawdust per hour, memproduksiseragam, high-density extrusions perfect for carbonization.

Fitur utama:

- High pressure & kontrol suhu for optimal extrusion

- Durable steel construction for African operational conditions

- Adjustable output size to match client needs

2. Tungku karbonisasi (Turning Extrusions into Charcoal)

After extrusion, the sawdust logs are carbonized in a kiln or furnace (provided by Weiwa or sourced locally). The trial showed that our extruded sawdust carbonizes faster than loose sawdust, menghasilkan90% charcoal yield.

3. Mesin briket arang (Optional Final Product Shaping)

For clients wanting briquettes instead of logs, kamimesin briket arang compresses carbonized sawdust into seragam, market-ready briquettes. The Zimbabwe trial produced mulus, Briket padatDenganNilai kalori tinggi.

Trial Results: What We Achieved in Zimbabwe

Machine Performance

- Extruder Efficiency: Processed 1.2 tons of sawdust/hour with minimal downtime.

- Carbonization Success: Extruded sawdust turned into 90% pure charcoal within 4-6 jam.

- Briquette Quality: Final briquettes had <5% breakage rateDanhigh market appeal.

Client Feedback

The Zimbabwean client was impressed by:

Konsumsi energi rendahDibandingkan dengan metode tradisional

Ease of operation (minimal training needed)

High-quality charcoal output (sold at premium prices)

Why Choose Weiwa Machinery for African Projects?

1. Proven Expertise in Sawdust Charcoal Machines

Denganpengalaman bertahun -tahun, Weiwa has supplied charcoal production lines to Africa, Asia, dan di luar, adapting machines to local conditions.

2. Solusi yang dapat disesuaikan

Apakah Anda memerlukansmall-scale briquette machine or a full sawdust extruder line, we tailor equipment to your production goals.

3. Dukungan setelah penjualan

Kami menyediakanPanduan Instalasi, pelatihan, and spare parts to ensure smooth operations in Zimbabwe and other African regions.

Kesimpulan: Sawdust Charcoal is the Future for Zimbabwe

The trial proved that Weiwa’s sawdust extruder and charcoal briquette machine can efficiently convert waste into profitable, eco-friendly fuel. For Zimbabwean entrepreneurs, this means:

✔Sustainable income from sawdust waste

✔Cleaner, better charcoal for local markets

✔Reliable machinery from a trusted supplier (Mesin Weiwa)

If you’re in Zimbabwe or Africa and interested in sawdust charcoal production, contact Weiwa Machineryuntuk sebuahcustomized solution.

Tentang mesin Weiwa

Mesin Weiwa is a leading manufacturer of biomass and charcoal production equipment, berspesialisasi dalamsawdust extruders, Briket mesin, Dan complete carbonization lines. Denganover three decades of experience, we serve clients in Afrika, Asia, dan di luar, menyediakantahan lama, high-performance machines tailored to local needs. Our commitment to kualitas, inovasi, dan dukungan pelanggan makes us the preferred partner for sustainable fuel solutions.

- Massa:+8613838093177

- Whatsapp:+8613838093177

- E-mail:info@cjlmachineGroup.com

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177