A New Era of Charcoal Production in the Philippines

Dalam beberapa tahun terakhir, permintaan untukefisien, eco-friendly charcoal production has surged across the Philippines and Southeast Asia, driven by both industrial needs and environmental regulations. To meet this growing demand, Mesin Weiwa recently delivered a tungku karbonisasi berkelanjutan to a Philippine client, marking a significant step in modernizing local charcoal manufacturing.

Our engineers are now on-site in the Filipina, overseeing the installation and commissioning of the tungku karbonisasi berkelanjutan, ensuring optimal performance and client satisfaction.

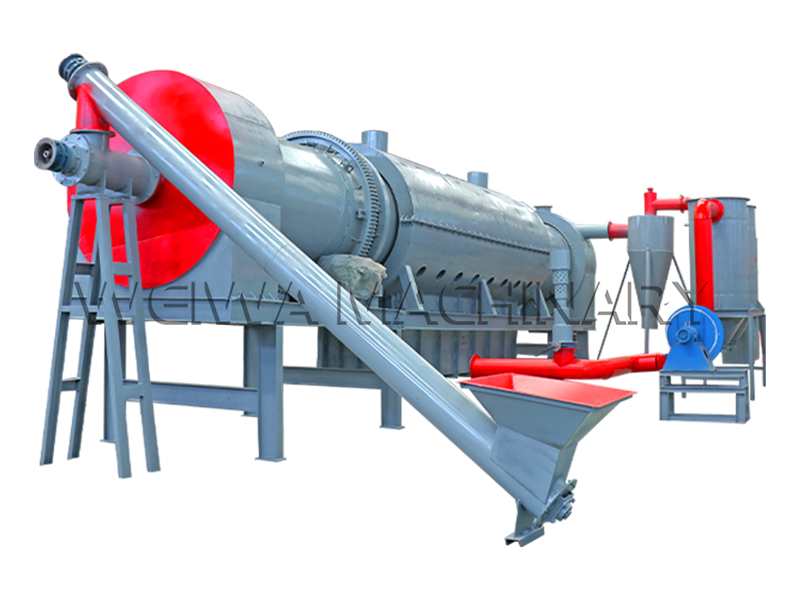

Apa itu Tungku karbonisasi berkelanjutan?

Atungku karbonisasi berkelanjutan is an advanced charcoal-making machine designed to convert biomass (seperti kayu, Kerang kelapa, dan sekam padi) into high-quality charcoal through a controlled carbonization process. Tidak seperti metode karbonisasi batch tradisional, which require frequent shutdowns for loading and unloading, atungku karbonisasi berkelanjutan operates non-stop, improving efficiency and reducing labor costs.

Key Features of Weiwa’s Continuous Carbonization Furnace

- Efisiensi tinggi: Processes raw materials continuously, maximizing output.

- Kepatuhan lingkungan: Equipped with smoke purification systems to minimize emissions.

- Energy-Saving Design: Utilizes waste heat recovery to reduce fuel consumption.

- Konstruksi yang tahan lama: Dibangun denganhigh-temperature-resistant materials for long-term use.

This technology is particularly valuable in the Filipina, dimanabiomass waste is abundant, and there is a rising demand for pembersih, more efficient charcoal production.

On-Site Installation & Testing in the Philippines

Our team of experienced engineers is currently in the Filipina, working closely with the client to ensure the tungku karbonisasi berkelanjutan is installed correctly and performs at its best.

Installation Process

- Site Preparation: Ensuring the foundation and utilities (listrik, air, dll.) meet requirements.

- Furnace Assembly: Carefully assembling the furnace components for optimal performance.

- System Integration: Connecting the carbonization furnace with makanan, pemakaian, and smoke purification systems.

Testing & Performance Results

Once installed, the furnace undergoes rigorous testing to verify:

- Efisiensi Karbonisasi: How well it converts raw materials into charcoal.

- Production Capacity: Whether it meets the client’s expected output.

- Pengendalian Emisi: Ensuring minimal smoke and pollutants.

https://youtube.com/shorts/8TAo8zZOVZU

Early results are promising, with the furnace demonstrating Operasi yang stabil, high charcoal yield, and low energy consumption. The client has reported satisfaction with the machine’s performance, and we expect full operational readiness soon.

Why the Philippines Needs Continuous Carbonization Furnaces?

TheFilipina, along with other Southeast Asian countries, faces increasing demand for arang due to:

- Cooking & Domestic Use: Charcoal remains a primary fuel source for households.

- Industrial Applications: Digunakan dimetalurgi, pertanian, and food processing.

- Peraturan lingkungan: Stricter rules on open burning and pollution control push for cleaner production methods.

Traditional charcoal-making methods (such as pit kilns or drum burners) are inefficient, polluting, and labor-intensive. Thetungku karbonisasi berkelanjutan offers a modern, sustainable alternative that aligns with global and local environmental standards.

Market Potential in Southeast Asia

Beyond the Filipina, countries like Indonesia, Malaysia, Vietnam, dan Thailand also have high biomass availability and growing charcoal demands. Weiwa Machinery is actively expanding its presence in these markets, menawarkantailored solutions for different raw materials and production scales.

Weiwa Machinery’s After-Sales Support & Expertise

One of the key advantages of choosing Mesin Weiwa is our comprehensive after-sales service, ensuring clients get the most out of their investment.

Our Support Includes:

- On-Site Engineer Training: Teaching operators how to run the furnace safely and efficiently.

- Maintenance Guidance: Helping clients perform routine checks to extend equipment lifespan.

- Troubleshooting Assistance: Quick remote or on-site support for any technical issues.

Kamiengineers in the Philippines are not just installing the furnace—they are building a long-term partnership with the client, ensuring smooth operations for years to come.

Weiwa Machinery’s Commitment to Sustainable Charcoal Production

The successful delivery and installation of our continuous carbonization furnace in the Philippines highlight Weiwa Machinery’s leadership in biomass carbonization technology. Denganproven performance, strong market demand, and dedicated after-sales support, we are confident that this technology will transform charcoal production in the Philippines and beyond.

As we continue to expand in Asia Tenggara, we remain committed to providing inovatif, ramah lingkungan, and efficient solutionsuntuk klien kami.

Tentang Mesin Weiwa

Mesin WeiwaAdalah produsen terkemukabiomass carbonization and charcoal-making equipment, berspesialisasi dalamtungku karbonisasi berkelanjutan, mesin briket arang, dan mesin terkait. Denganpengalaman bertahun -tahun, kami melayani klien di seluruh dunia, menawarkansolusi khusus, kinerja yang dapat diandalkan, and professional after-sales service.

Our mission is to promote sustainable charcoal production through advanced technology and exceptional customer support. Whether you’re in the Filipina, Indonesia, or anywhere else, Weiwa Machinery adalah mitra terpercaya Andahigh-efficiency carbonization solutions.

📞Hubungi kami hari ini to learn more about our continuous carbonization furnaces and how we can support your charcoal production needs.

- Massa:+8613838093177

- Whatsapp:+8613838093177

- E-mail:info@cjlmachineGroup.com

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177