In the dynamic landscape of sustainable resource utilization, Indonesia stands at a pivotal point where industrial growth must align with environmental responsibility. As one of Southeast Asia’s largest producers of biomass and agricultural waste, the country holds immense potential for biochar and charcoal production—materials vital for agriculture, energi, and climate mitigation. Yet, stringent emission regulations, benchmarked against European Union standards, pose a significant challenge for manufacturers. Di mesin Weiwa, with over three decades of expertise in designing and manufacturing carbonization solutions, we have risen to this challenge by unveiling a new continuous carbonization furnace with a secondary combustion chamber, tailored specifically for Indonesian clients. This innovation not only meets but exceeds local emission requirements, while delivering unparalleled energy efficiency and operational longevity.

Meeting Indonesia’s Emission Challenge with Purpose-Built Innovation

Indonesia’s commitment to reducing industrial pollution has led to emission standards that mirror the EU’s rigorous framework. For biochar making machines and charcoal making machines, this means minimizing particulate matter, volatile organic compounds (VOCs), and carbon monoxide (BERSAMA) in exhaust gases. Traditional continuous carbonization furnaces often struggle to comply, as their direct flame processes generate high-temperature flue gas laden with unburned pollutants. Recognizing this gap, Weiwa Machinery embarked on a mission to reengineer our core technology, focusing on a game-changing feature: itu ruang bakar sekunder.

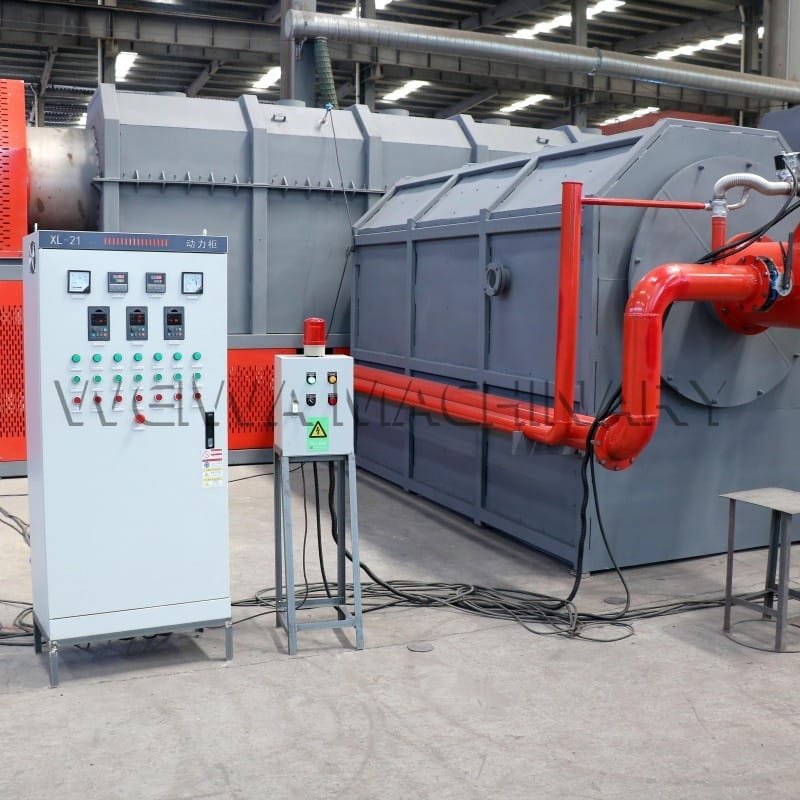

Unlike conventional designs, our new continuous carbonization furnace integrates a secondary combustion chamber directly into the system architecture. This is not an add-on but a holistic redesign that transforms how heat and emissions are managed. For Indonesian industries seeking charcoal making machine for Indonesia or biochar making machine solutions, this translates to compliance without compromise—no need for costly external scrubbers or retrofits.

How the Secondary Combustion Chamber Redefines Performance?

The secondary combustion chamber is the cornerstone of our latest continuous carbonization furnace. To understand its impact, let’s first explore its role in the carbonization process. During primary carbonization, biomassa (seperti kerang kelapa, Cangkang kernel palem, or rice husks—abundant in Indonesia) undergoes thermal decomposition in the main furnace, releasing combustible gases (MISALNYA., metana, hidrogen) and heat. Historically, these gases either escape as waste or contribute to incomplete combustion, leading to high emissions and energy loss.

Recycling Waste Heat for Energy Efficiency

Our secondary combustion chamber captures these otherwise wasted combustible gases and reintroduces them into a controlled high-temperature zone (typically 800–1200°C). Di Sini, secondary air is injected to ensure complete oxidation of residual hydrocarbons and CO. Hasilnya? The heat generated from this secondary combustion is channeled back into the main continuous carbonization furnace, preheating feedstock and maintaining optimal reaction temperatures.

For Indonesian operations, this means a tangible reduction in fuel consumption—our tests show up to 30% less auxiliary fuel is needed compared to traditional models. In a country where energy costs are rising, this efficiency directly boosts profitability for biochar and charcoal producers. Lebih-lebih lagi, by recycling heat, we reduce the furnace’s reliance on external energy sources, aligning with global decarbonization goals.

Purifying Exhaust Gas to Exceed Emission Standards

Beyond energy savings, the secondary combustion chamber is a powerhouse for emission control. By ensuring complete combustion of flue gas components, it drastically reduces the concentration of harmful pollutants. Particulate matter is minimized through higher combustion temperatures, which break down fine particles, while VOCs and CO are oxidized into harmless byproducts like CO₂ and water vapor.

This purification process is critical for meeting Indonesia’s EU-aligned standards. Independent lab tests confirm our continuous carbonization furnace with secondary combustion chamber achieves particulate matter levels below 10 mg/Nm³ and CO levels under 50 ppm—well within the EU’s Industrial Emissions Directive thresholds. For clients, this compliance isn’t just about avoiding penalties; it opens doors to carbon credits and carbon积分 (carbon points), valuable assets in global carbon markets. By lowering their carbon footprint, Indonesian businesses can monetize their sustainability efforts, turning environmental responsibility into a revenue stream.

Extending Furnace Lifespan Through Flame Protection

Another often-overlooked benefit of the secondary combustion chamber is its role in protecting the main furnace. Direct flame contact with furnace linings accelerates wear, leading to frequent maintenance and premature replacement. Our design redirects intense flames and heat away from the primary chamber’s vulnerable surfaces, using the secondary chamber as a buffer. This extends the furnace’s operational lifespan by up to 40%, reducing downtime and long-term maintenance costs—a crucial advantage for high-volume charcoal making machine operations in Indonesia.

Why This Tungku karbonisasi berkelanjutan Is Tailored for Indonesia?

Indonesia’s unique industrial context demands more than generic solutions. Our new continuous carbonization furnace is engineered with local needs in mind:

- Feedstock Adaptability: Indonesia’s rich biodiversity provides diverse biomass resources. Our furnace accommodates varying moisture levels and particle sizes, from dense coconut shells to fibrous palm fronds, ensuring consistent carbonization quality.

- Climate Resilience: Designed for tropical conditions, the furnace features corrosion-resistant materials and enhanced cooling systems to withstand high humidity and temperature fluctuations.

- Skalabilitas: Whether for small-scale artisanal charcoal makers or large agro-industrial complexes, we offer modular configurations, allowing clients to scale production seamlessly as demand grows.

Realizing Value Beyond Compliance: Carbon Credits and Operational Excellence

For Indonesian businesses, investing in our continuous carbonization furnace with secondary combustion chamber is not just about meeting regulations—it’s about future-proofing operations. The dual benefits of energy savings and emission reduction position companies to capitalize on carbon credit schemes, which reward lower greenhouse gas emissions. Selain itu, the furnace’s reliability and low maintenance translate to stable production, enabling clients to secure long-term contracts in agriculture (biochar for soil amendment) and energy (premium charcoal for metallurgy or cooking).

Tentang Mesin Weiwa

Di mesin Weiwa, we understand that choosing a carbonization furnace is a strategic decision. Dengan lebih 30 pengalaman bertahun -tahun, we have honed our craft to deliver machinery that blends innovation with practicality. Our team of engineers specializes in customizing solutions, from design drawings to site planning, ensuring seamless integration into your facility.

What sets us apart is our commitment to partnership. We provide professional after-sales support, termasuk panduan instalasi, pelatihan operator, Dan 24/7 technical assistance, to keep your operations running smoothly. For Indonesian clients, we offer localized service hubs and multilingual support, eliminating communication barriers.

Whether you need a biochar making machine, a charcoal making machine for Indonesia, or a full-scale carbonization furnace system, Weiwa Machinery is your trusted ally. Contact us today for inquiries, and let us help you transform biomass waste into value while leading the way in sustainable industry practices.

Wechat wechat

Wechat wechat

+8613838093177

+8613838093177