工业木芯片木炭块生产线是一种高级设备,可有效利用生物质废物(例如木屑),稻壳,花生壳,木屑材料. 旨在将木屑转换为高热量木炭块,以满足对环保燃料的市场需求. 随着可持续发展的概念变得越来越受欢迎, 木芯片木炭块由于其低污染和高效率而逐渐受到广泛关注.

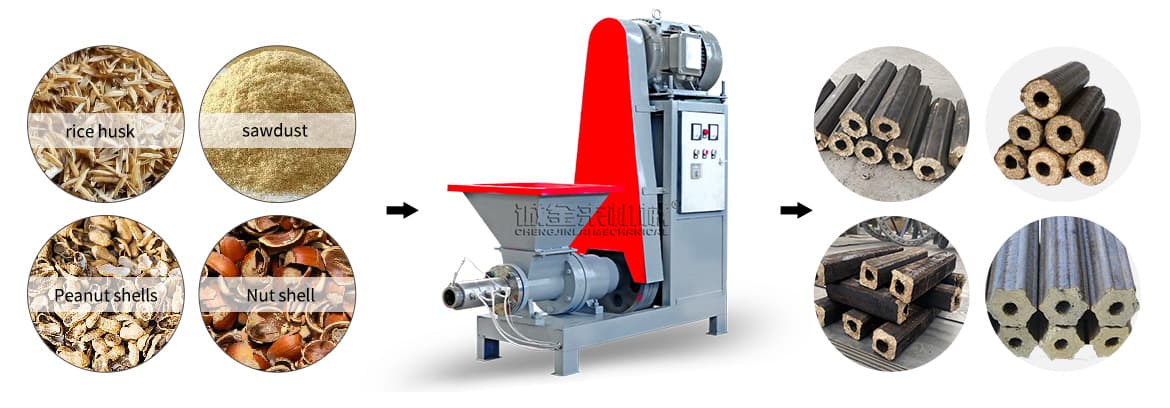

木炭制造机器原材料 & 最终产品

木炭制造机具有广泛的原材料,例如木材原木, 竹子, 椰子壳, 棕榈贝壳, 木屑, 稻壳, 坚果壳, 核桃壳和各种生物质原材料.

原材料是石墨粉, 煤粉或矿物粉, 它可以直接压碎,并添加到适当的binder和均匀搅拌和制作杆之前均匀搅拌.

(尺寸:少于 5 毫米;水分含量:少于 25%)

最终产品:

◆这个生物燃料直径为45-80mm, 发生在空心四角或六角形圆柱或空心六角形中,并通过人体15-20mm孔.

◆可用的形状: 正方形, 六角形, 五角大楼, 五角大楼带边缘, 六角形的边缘.

◆可用的直径可能是: 50毫米,60毫米,70毫米,80MM等

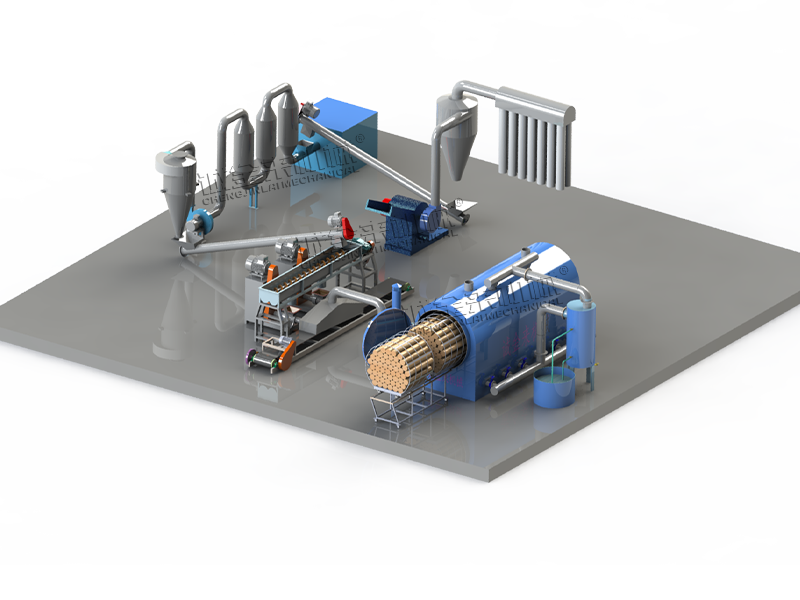

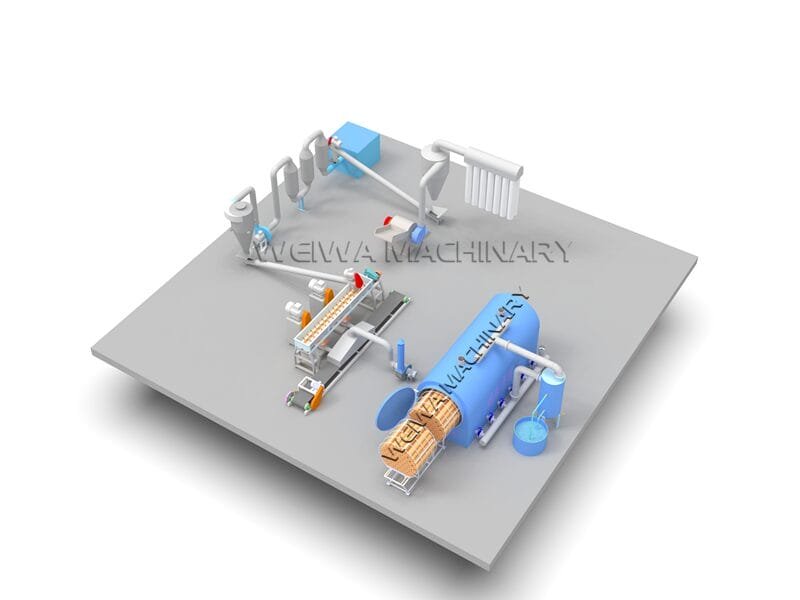

木炭煤片生产线过程流量

步 1. 磨床将原材料粉碎成小块 (直径约为3-5mm)

步 2. 干燥机将原材料干燥,直到水分小于 12%

步 3. 将材料放入木制煤球机中,而无需添加任何化学品,

步 4. 碳化木煤棒

步 5. 成品木炭可以是45mm , 50毫米,60毫米 ,70毫米 ,80毫米直径

A.Drum Chipper是生产各种高质量木屑的特殊设备. 它可以将原木和小直径木材切成均匀尺寸和扁平切割的高品质木片.

B.双口碎器是一种精美的压碎设备,可以处理各种木材, 木材废料, 分支, 分支, 木屑, 板装饰, 吠, 竹子, 竹皮和其他原材料一次进入木屑.

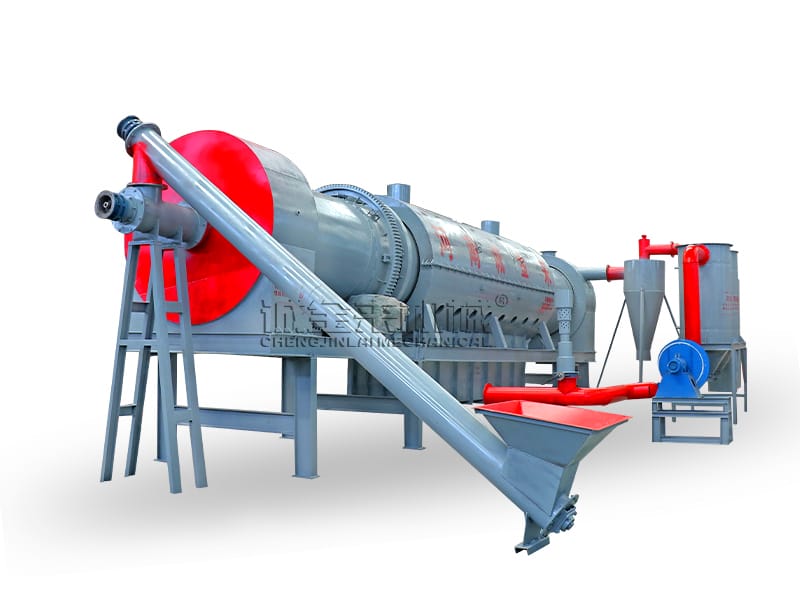

C.Rotary鼓式干燥机是传统的干燥设备之一, 这是可靠的, 操作灵活, 适应性强, 而且处理能力很大. 根据干燥要求确定设备的直径和长度.

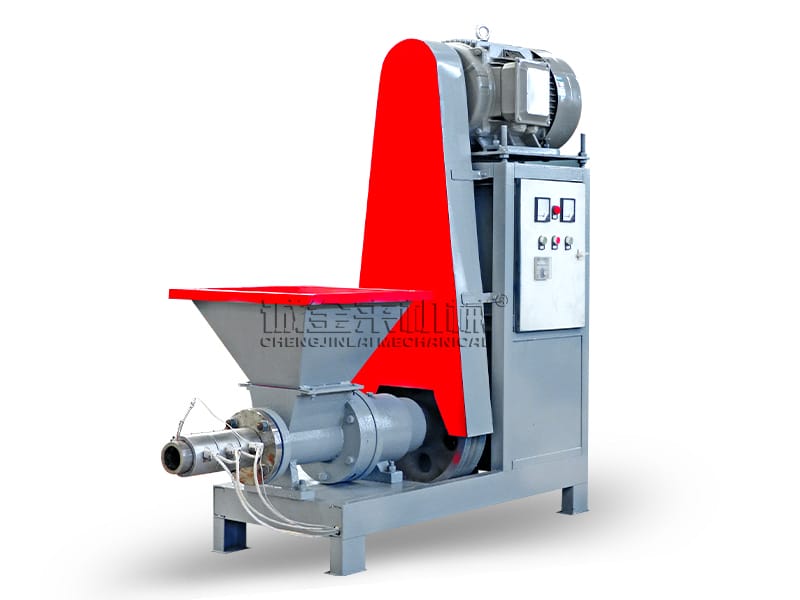

D.Wood Charcoal Briquette Machine是一种形成的设备, 哪个主要通过合格的木屑和木材材料或生物质材料 (尺寸低于5mm, 12% 水分) 通过螺旋, 高压形成气缸和加热环. 机械杆在高温和高压下形成.

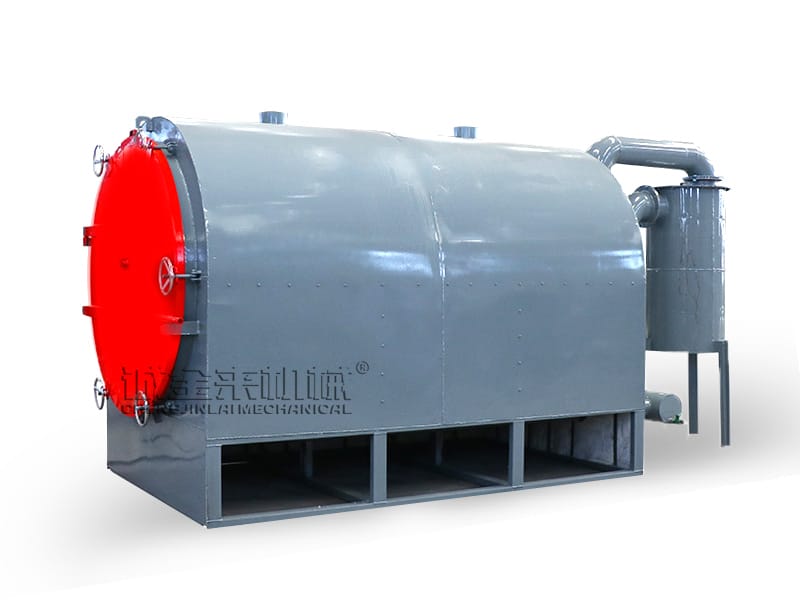

E.Hoisting碳化炉是一种环保且无烟的碳化设备. 它不仅可以碳化机器制造的杆, 但也直接碳化原材料(例如原材料), 木块, 椰子壳, 和树皮.

我们提供 100% 免费木炭机生产线设计

当您打算配置碳化生产线时, 请让我们知道您的详细信息.

这些材料包括:

1.原材料类型, 尺寸, 水分

2.植物尺寸

3.变压器容量

4.成品的类型和大小

5.对产出的需求

尽可能详细, 最好的, 为了自定义自己的碳化生产线设备, 我们将免费为您提供3D站点计划图.

*不同的材料将被设计为不同的生产解决方案, 咨询时客户需要通知我们材料’ 水分, 粒度, 屈服, 煤球大小, 形状, 某些特殊情况可能需要辅助设备,例如其他类型的破碎机,其他类型的混合器,屏幕网格, 振动筛, 粘合剂喂食器, 液体混合罐, 磁分离器, 电子带称重器, 可变频率驱动器.

总之, 工业木屑木炭块生产线是重要的环境保护技术. 它有效地将木芯片资源转换为高价值燃料,并有助于实现可持续发展的目标. 如果您对设备感兴趣或有任何疑问, 请留言,我们将全心全意地为您提供专业的答案和解决方案!

相关文章

微信

微信

+8613838093177

+8613838093177